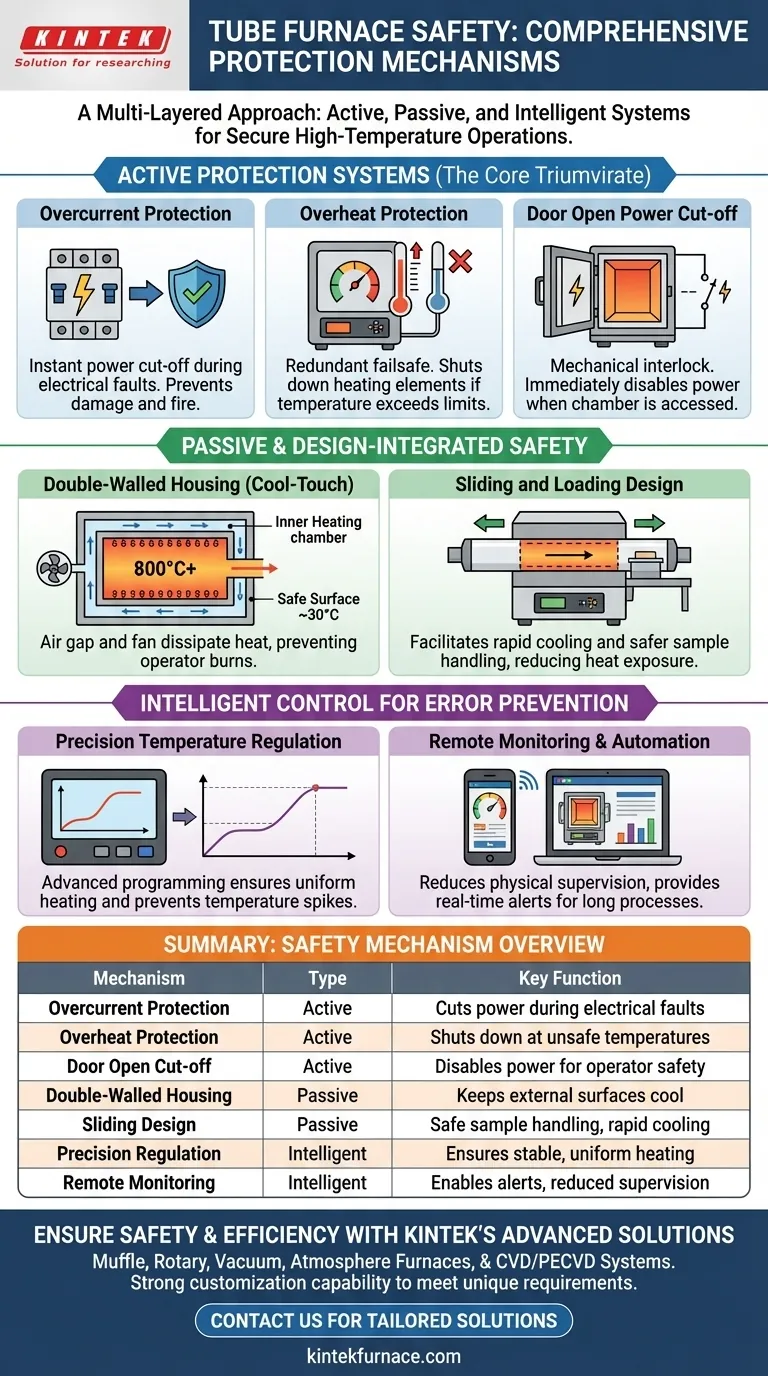

In any high-temperature environment, safety is non-negotiable. Tube furnaces are engineered with several critical, built-in safety mechanisms to protect both the operator and the equipment from abnormal conditions. The most fundamental of these are overcurrent protection, overheat protection, and an automatic power cut-off interlock connected to the furnace door. These systems work in concert to prevent accidents and equipment failure during demanding thermal processes.

True furnace safety is not about a single feature, but a comprehensive system. It combines active electronic cut-offs, passive design elements like cool-touch housing, and intelligent controls to create a secure operating environment.

The Core Triumvirate: Active Protection Systems

Every modern tube furnace should be equipped with a baseline of active safety systems that automatically respond to dangerous conditions. These are your first line of defense against common operational failures.

Overcurrent Protection

This system functions like a sophisticated circuit breaker designed specifically for the furnace. It continuously monitors the electrical current drawn by the heating elements.

If a short circuit or other electrical fault causes a surge in current, this protection instantly cuts power. This prevents damage to the furnace's sensitive electronics and significantly reduces the risk of an electrical fire.

Overheat Protection

This is arguably the most critical safety feature for preventing catastrophic failure. It acts as a redundant failsafe for the primary temperature controller.

A separate thermocouple and controller monitor the furnace temperature independently. If the main controller fails and the temperature rises above a pre-set safety limit, this secondary system will forcibly shut down the heating elements, protecting your sample, the heating elements, and the furnace integrity.

Door Open Power Cut-off

This is a simple but essential mechanical interlock. When the furnace door or chamber is opened, a switch is triggered that immediately cuts power to the heating elements.

This feature directly protects the operator from exposure to extreme temperatures and accidental contact with live electrical components inside the heating chamber.

Passive and Design-Integrated Safety

Beyond active electronic cut-offs, the physical design of the furnace plays a crucial role in day-to-day safety. These features are built into the structure of the equipment to minimize inherent hazards.

Double-Walled Housing

Modern furnaces often feature a double-walled or "double housing" design. An air gap, sometimes assisted by a cooling fan, separates the inner heating chamber from the external casing.

This design is remarkably effective at dissipating heat. Even when the internal temperature is at 800°C or higher, the external surface can remain at a safe-to-touch temperature of around 30°C, drastically reducing the risk of operator burns.

Sliding and Loading Design

Some furnace designs incorporate a sliding mechanism for the tube. This allows the hot zone to be moved away from the sample quickly, enabling rapid cooling.

This not only benefits the thermal process but also enhances safety by allowing for faster and safer loading and unloading of samples, reducing the operator's exposure time to residual heat.

The Role of Intelligent Control in Preventing Errors

The furnace's control system is a key component of its safety profile. By automating processes and ensuring precision, it helps to mitigate the single largest risk factor in any lab: human error.

Precision Temperature Regulation

Advanced digital controllers, which can be programmed with multiple temperature ramps and holds, ensure highly uniform and predictable heating.

By preventing temperature overshoots and providing stable control, these systems reduce the risk of damaging the sample or exceeding the furnace's operational limits.

Remote Monitoring and Automation

Many contemporary furnaces are equipped with intelligent control systems that allow for remote monitoring via a network.

This capability is invaluable for long-duration processes, as it reduces the need for constant physical supervision and allows for immediate alerts if any parameters deviate from the setpoints.

Understanding the Trade-offs and Limitations

While these systems provide robust protection, it's critical to recognize their limitations. No safety feature is a substitute for proper training and maintenance.

Reliance on Sensor Integrity

Active protections like the overheat cut-off are entirely dependent on the proper functioning of their sensors (thermocouples). Regular inspection and calibration are essential to ensure they will work when needed.

User Training is Irreplaceable

Safety systems are designed to protect against equipment failure and common mistakes, not deliberate misuse. A user must still be trained on proper operating procedures, chemical compatibility for their samples, and emergency shutdown protocols.

Not All Features are Standard

Basic or older furnace models may lack advanced features like double-walled housing or sophisticated programmable controllers. Always verify the specific safety features included with your particular unit before operation.

Making the Right Choice for Your Goal

When evaluating a tube furnace, align its safety features with your intended application.

- If your primary focus is routine, supervised lab work: Ensure the furnace has the core active protections: overcurrent, overheat, and a door power interlock.

- If your primary focus is running long, unattended processes: Prioritize models with intelligent controls, remote monitoring capabilities, and a highly reliable overheat protection system.

- If your primary focus is high-throughput use or operator safety in a teaching environment: A cool-touch double-walled housing and a design that simplifies sample loading are critical features to minimize accidents.

Understanding these layers of protection empowers you to operate your equipment with both confidence and competence.

Summary Table:

| Safety Mechanism | Type | Key Function |

|---|---|---|

| Overcurrent Protection | Active | Cuts power during electrical faults to prevent damage and fire |

| Overheat Protection | Active | Shuts down heating elements if temperature exceeds safe limits |

| Door Open Power Cut-off | Active | Disables power when door is opened for operator safety |

| Double-Walled Housing | Passive | Keeps external surfaces cool to prevent burns |

| Sliding and Loading Design | Passive | Allows safe sample handling and rapid cooling |

| Precision Temperature Regulation | Intelligent | Prevents overshoots and ensures stable heating |

| Remote Monitoring and Automation | Intelligent | Enables alerts and reduces need for physical supervision |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable tube furnaces and other products like Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, enhancing protection and performance. Contact us today to discuss how we can support your specific needs and deliver tailored solutions for safer, more effective thermal processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents