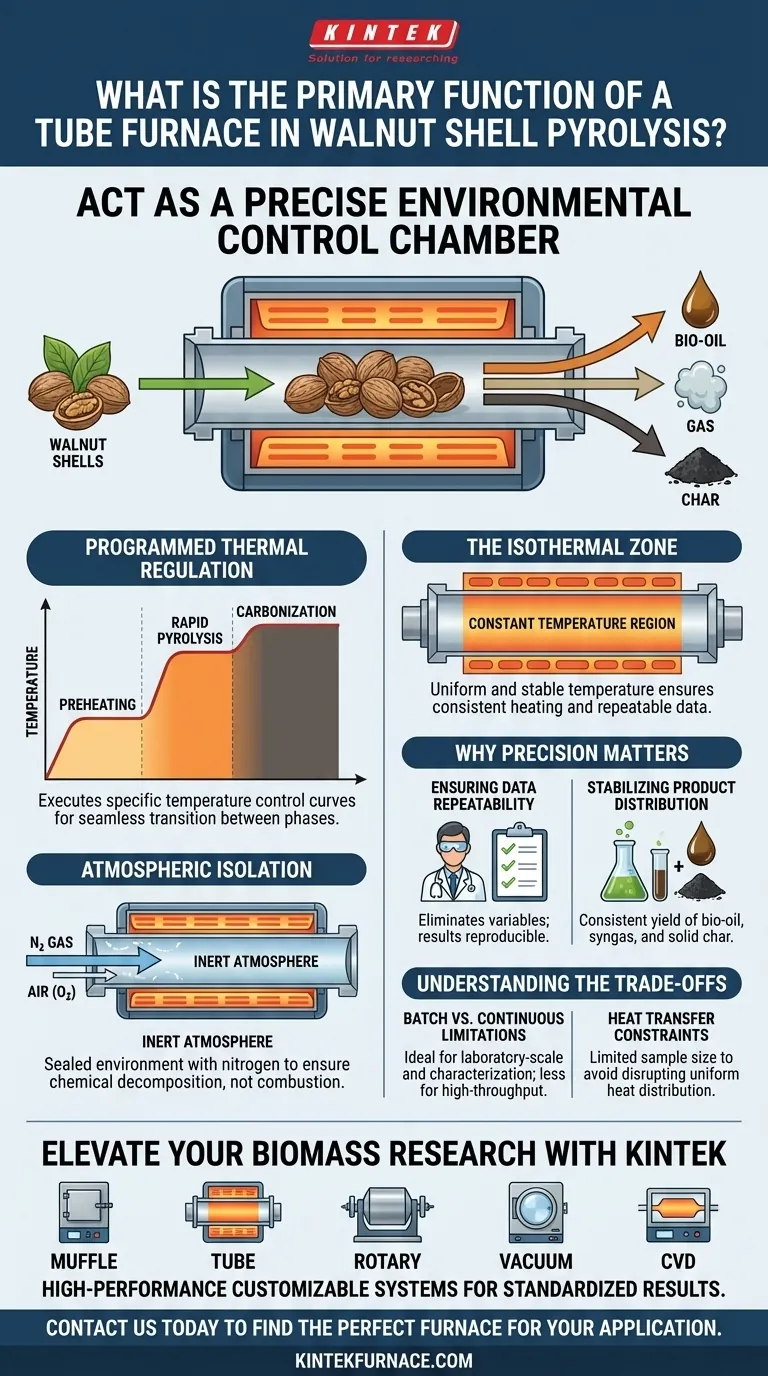

The primary function of a tube furnace in walnut shell pyrolysis is to act as a precise environmental control chamber. It facilitates the complete thermochemical transformation of the biomass by maintaining a programmed high-temperature profile within a nitrogen atmosphere. This equipment manages every stage of the process—including preheating, rapid pyrolysis, and carbonization—to ensure the reaction occurs under strictly regulated conditions.

The tube furnace is not merely a heat source; it is the instrument of standardization. By creating a constant isothermal zone, it guarantees the repeatability of experimental data and ensures the stable distribution of end products like bio-oil, gas, and char.

The Mechanics of Controlled Transformation

Programmed Thermal Regulation

The tube furnace goes beyond simple heating by executing a specific, programmed temperature control curve. This allows for the seamless transition between critical phases: preheating the biomass, initiating rapid pyrolysis, and sustaining carbonization. The ability to ramp temperature at specific rates is essential for influencing how the walnut shells decompose.

Atmospheric Isolation

To achieve pyrolysis rather than combustion, the reaction must occur in the absence of oxygen. The tube furnace creates a sealed environment where nitrogen gas is introduced to displace air. This inert atmosphere ensures that the walnut shells undergo thermal decomposition chemically, rather than burning physically.

The Isothermal Zone

A critical feature of the tube furnace is the creation of a constant temperature isothermal zone. Within this specific region of the tube, the temperature is uniform and stable. This ensures that the entire sample of walnut shells is subjected to the exact same thermal energy, preventing uneven processing or incomplete reactions.

Why Precision Matters for Biomass

Ensuring Data Repeatability

In scientific experimentation, results must be reproducible to be valid. The tube furnace eliminates variables by strictly controlling the heating rate and peak temperature. This allows researchers to attribute changes in the output solely to the material properties of the walnut shells, rather than fluctuations in the equipment.

Stabilizing Product Distribution

The yield of bio-oil, syngas, and solid char is highly sensitive to temperature fluctuations. By maintaining strict thermal stability, the tube furnace ensures a consistent distribution of these products. This stability is required to characterize the material accurately or to optimize the process for a specific product, such as high-quality biochar.

Understanding the Trade-offs

Batch vs. Continuous Limitations

While tube furnaces offer exceptional control, they are typically designed for batch or semi-continuous processing. This makes them ideal for laboratory-scale experiments and material characterization but less suitable for high-throughput industrial production without modification.

Heat Transfer Constraints

The reliance on conductive and radiative heat transfer within a tube means that sample size is limited. Overloading the tube can disrupt the uniform heat distribution, leading to thermal gradients within the biomass sample that compromise the data.

Making the Right Choice for Your Goal

To maximize the utility of a tube furnace for biomass pyrolysis, consider your specific objectives:

- If your primary focus is Fundamental Research: Prioritize the precision of the programmed temperature control to isolate specific reaction kinetics and ensure data reproducibility.

- If your primary focus is Material Engineering: Focus on the atmosphere control and isothermal stability to optimize the pore structure and carbonization degree of the resulting char.

The tube furnace is the defining tool for converting raw biomass into standardized, analyzable data and materials.

Summary Table:

| Feature | Function in Biomass Pyrolysis | Benefit to Research |

|---|---|---|

| Programmed Heating | Executes specific temperature ramps | Enables precise control over decomposition kinetics |

| Atmospheric Control | Displaces oxygen with inert nitrogen | Prevents combustion to ensure pure thermochemical pyrolysis |

| Isothermal Zone | Maintains a uniform temperature region | Ensures consistent heating and repeatable experimental data |

| Process Management | Controls preheating and carbonization | Optimizes the yield of bio-oil, syngas, and biochar |

Elevate Your Biomass Research with KINTEK

Maximize the precision of your thermochemical transformations with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the unique demands of your lab. Whether you are optimizing biochar quality or analyzing reaction kinetics, our furnaces provide the isothermal stability and atmospheric control necessary for standardized results.

Ready to standardize your experimental data? Contact us today to find the perfect furnace for your application.

Visual Guide

References

- Wenjing He, Yibo Zhao. Catalytic pyrolysis and <i>in situ</i> carbonization of walnut shells: poly-generation and enhanced electrochemical performance of carbons. DOI: 10.1039/d4ra01608d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace with precise temperature control necessary for synthesizing high-quality monolayer MoS2?

- How do precision drying ovens and programmable furnaces ensure metal nitride/TiO2 composite performance? Expert Guide

- What is the primary purpose of using a Quartz Tube Furnace for MoS2 annealing? Unlock High Electrical Performance

- What is the role of high-temperature tube furnaces in the post-processing of graphite oxide nanostructures?

- What is the primary use of a laboratory tube furnace in biomass carbonization processes? Precision Biochar Engineering

- How do laboratory tube furnaces contribute to the sintering of Ba0.95La0.05(Fe1-xYx)O3-δ? Precise Atmosphere Control

- What are the advantages of using industrial aluminum profiles for tube furnaces? Achieve Modular Lab Efficiency

- Why is a tube furnace essential for Ru-TiO2/PC catalyst synthesis? Master Complex Atmosphere Control