Yes, a quartz tube furnace is safe to operate at high temperatures, but this safety is entirely conditional on using the correct tube material for your target temperature and adhering to strict operational protocols. The term "quartz furnace" can be misleading, as the capabilities and safety limits are defined by the tube inside, which may be pure quartz glass or a more robust ceramic like alumina. Understanding this distinction is the key to preventing catastrophic failure.

The safety of a high-temperature tube furnace does not come from the furnace itself, but from a fundamental understanding of its components. The primary risk lies in exceeding the thermal limits of the process tube, making the choice between a quartz and an alumina tube the most critical safety decision you will make.

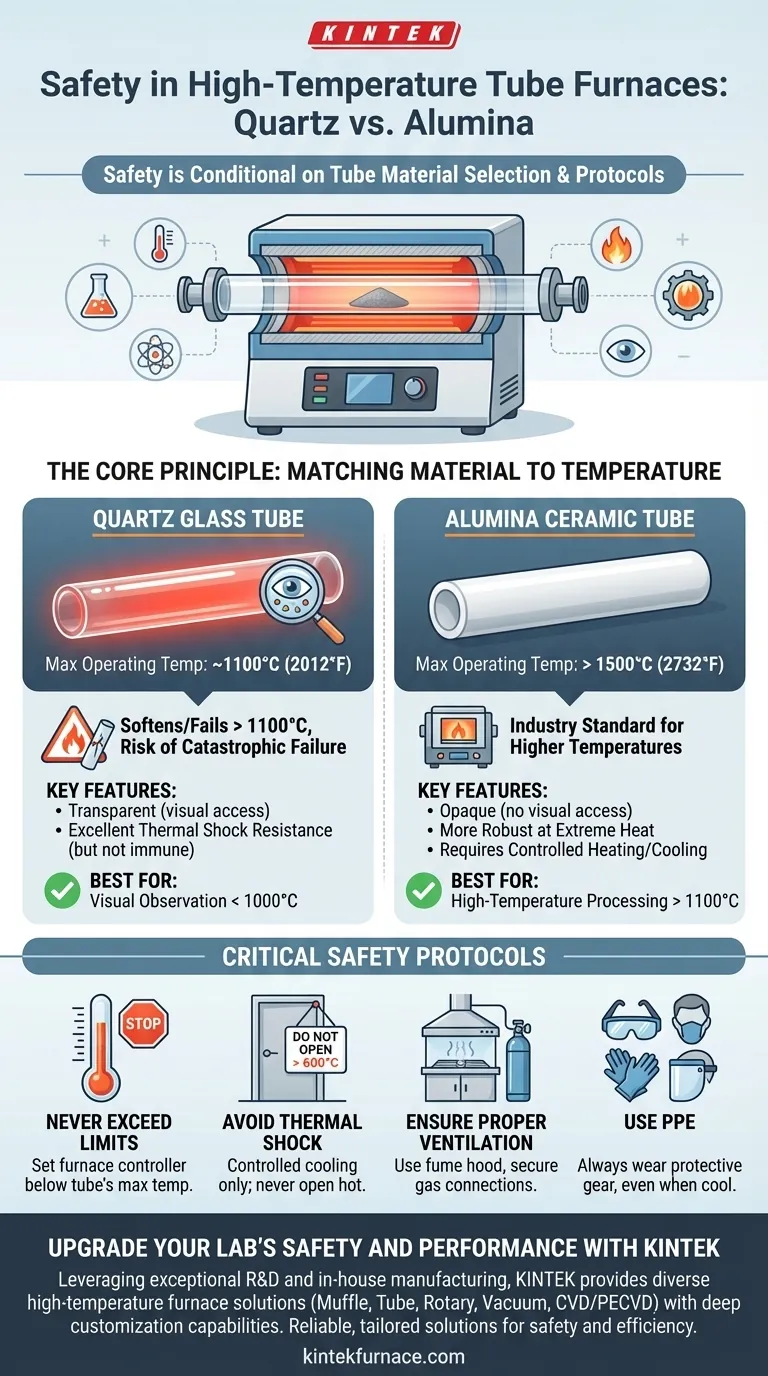

The Core Principle: Matching Material to Temperature

The single most important factor for safe operation is ensuring your process tube can handle the intended heat. The furnace is simply a heating element; the tube is the containment vessel that can fail.

What "High Temperature" Means for Quartz

A true quartz glass tube offers the significant benefit of transparency, allowing for direct visual observation of the sample.

However, quartz has a softening point. As temperatures approach and exceed 1100°C (2012°F), a standard quartz tube will begin to soften, deform, and can ultimately fail, especially under vacuum or pressure.

Using a pure quartz tube beyond this range is a significant safety risk.

The Alumina Alternative for Higher Temperatures

For applications requiring temperatures above the limits of quartz, the industry standard is to use a high-purity alumina (Al₂O₃) ceramic tube, sometimes referred to as a corundum tube.

These opaque white tubes are more robust at extreme temperatures, often rated for continuous use well above 1500°C (2732°F). Many "high-temperature" tube furnaces are designed specifically for use with alumina tubes.

The Furnace Body's Role in Safety

Modern furnace designs contribute to safety with features like double-wall insulation. This keeps the outer casing of the furnace cool to the touch, minimizing heat loss and reducing the risk of burns to operators.

Understanding the Trade-offs: Quartz vs. Alumina

Choosing the right tube involves balancing your experimental needs against the physical limitations of the materials. This is not a matter of preference but of safety and feasibility.

Key Advantage: Transparency

The primary reason to choose a quartz tube is visual access. If you need to observe a physical change like melting or a color shift in real-time, quartz is the only viable option. This benefit is lost with an opaque alumina tube.

Key Limitation: Maximum Operating Temperature

This is the most critical trade-off. Alumina has a significantly higher maximum operating temperature than quartz. Pushing a quartz tube beyond its softening point is a direct path to equipment failure and a compromised experiment.

Factor: Thermal Shock Resistance

Quartz has excellent resistance to thermal shock, meaning it can handle rapid temperature changes better than many other ceramics. However, it is not immune. Extremely rapid heating or cooling can still cause it to crack.

Alumina is also resistant to thermal shock but, like any ceramic, requires controlled heating and cooling rates to ensure a long service life and prevent cracking.

Critical Safety Protocols for Operation

Safe operation is a matter of procedure and discipline. Always adhere to these fundamental rules.

Never Exceed Material Temperature Limits

Know the specified maximum temperature for your specific process tube—whether it is quartz or alumina—and set the furnace controller well below that limit.

Avoid Thermal Shock at All Costs

A catastrophic failure mode for any ceramic tube is thermal shock. Never open the furnace door or end caps while the furnace is hot, especially above 600°C (1112°F). Always allow the furnace to cool down completely under a controlled program.

Ensure Proper Ventilation and Atmosphere

High-temperature processes can release fumes or require a specific controlled atmosphere (e.g., argon, nitrogen). Ensure the furnace is operated in a well-ventilated area or under a fume hood, and that all gas connections are secure and leak-free.

Use Appropriate Personal Protective Equipment (PPE)

Always wear safety glasses with side shields, and use insulated, high-temperature gloves when handling parts of the furnace assembly, even after it has had time to cool.

Making the Right Choice for Your Application

Your choice of tube material must be dictated by the goals of your experiment.

- If your primary focus is visual observation below 1000°C: A high-quality quartz process tube is the correct and safe choice.

- If your primary focus is processing materials above 1100°C: An alumina ceramic tube is the mandatory choice for safe and reliable operation.

- If your primary focus is chemical inertness: Both quartz and high-purity alumina are highly inert, but you must verify their compatibility with your specific reactants at the target temperature.

By understanding that the process tube, not the furnace, defines your operational limits, you can ensure both personal safety and the success of your work.

Summary Table:

| Tube Material | Max Temperature | Key Features | Best For |

|---|---|---|---|

| Quartz Glass | Up to 1100°C | Transparent, excellent thermal shock resistance | Visual observation below 1000°C |

| Alumina Ceramic | Above 1500°C | Opaque, robust at extreme temperatures | High-temperature processing above 1100°C |

Upgrade Your Lab's Safety and Performance with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need quartz tubes for visual access or alumina tubes for extreme heat, we deliver reliable, tailored solutions that enhance safety and efficiency.

Contact us today to discuss your specific needs and discover how our expertise can benefit your research!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing