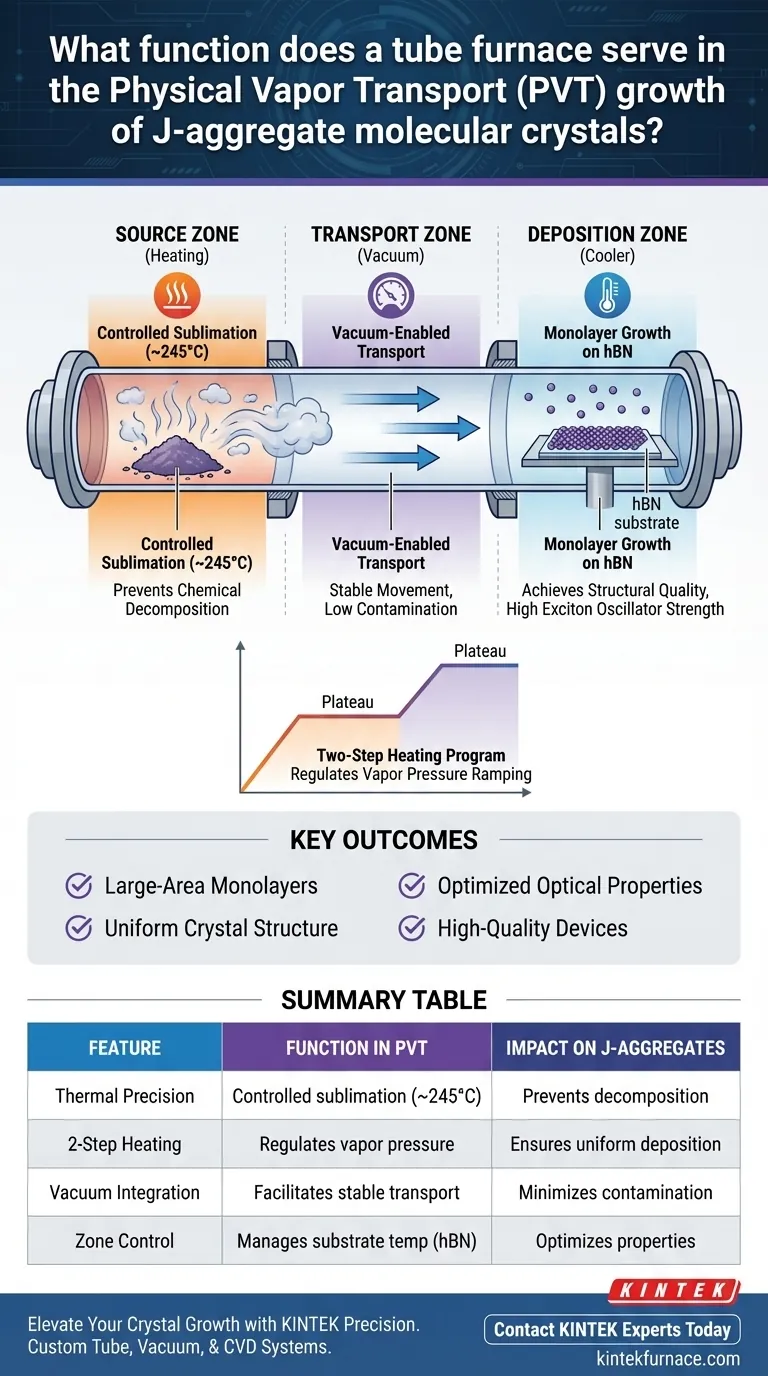

In the Physical Vapor Transport (PVT) growth of J-aggregate molecular crystals, the tube furnace functions as a strictly controlled thermal reaction chamber responsible for driving the sublimation and recrystallization process. It creates the precise environmental conditions required to vaporize organic source materials and deposit them onto a target substrate, typically hexagonal boron nitride (hBN), under a vacuum.

The tube furnace is not merely a heat source; it is a precision instrument that orchestrates the delicate phase transition of J-aggregate molecules. By executing specific multi-step heating programs, it enables the growth of large-area, high-quality monolayers essential for advanced optical performance.

The Mechanics of Thermal Control

Driving Controlled Sublimation

The primary function of the tube furnace is to reach specific temperature set points that trigger the phase change of the J-aggregate molecules.

Unlike inorganic materials that may require extreme heat, these organic molecules are processed at more moderate temperatures, such as 245 degrees Celsius.

The furnace provides the thermal energy necessary to turn the solid source material into vapor without causing chemical decomposition.

The Two-Step Heating Program

Success in PVT growth relies on more than just reaching a peak temperature; it requires a dynamic thermal profile.

The tube furnace utilizes a two-step heating program to regulate the rate of sublimation.

This programmable ramping ensures that the vapor pressure builds gradually, preventing uncontrolled bursts of material that could ruin the crystal structure.

Vacuum-Enabled Transport

The tube furnace works in conjunction with a vacuum system to facilitate the movement of molecules.

By maintaining a low-pressure environment, the furnace ensures the stable transport of the vaporized molecules from the source zone to the cooler deposition zone.

This vacuum environment minimizes contamination and allows the molecules to travel efficiently to the substrate.

Achieving Structural Quality

Substrate Compatibility

The furnace is designed to accommodate specific substrates that promote high-quality growth, such as hexagonal boron nitride (hBN).

The thermal environment within the tube ensures that the hBN substrate remains at the optimal temperature to receive the depositing molecules.

This compatibility is critical for defining the orientation and flatness of the resulting crystal.

Optimizing Material Properties

The ultimate goal of this precise thermal regulation is to produce large-area, monolayer molecular crystals.

Strict control over the heating and cooling cycles directly influences the electronic properties of the material.

Properly grown crystals exhibit significant exciton oscillator strength, a key metric for their utility in photonic and optoelectronic devices.

Understanding the Trade-offs

Precision vs. Throughput

The requirement for a "strictly controlled" environment means the process is inherently sensitive to variables.

A tube furnace offers high precision, but the reliance on specific heating programs and vacuum conditions can limit the speed of production compared to less rigorous deposition methods.

Thermal Sensitivity

Organic J-aggregates are far more thermally sensitive than inorganic crystals (like Molybdenum Phosphide, which might be grown at 700°C–900°C in similar equipment).

In the context of J-aggregates, slight deviations from the 245°C target can lead to incomplete sublimation or thermal degradation.

The trade-off is that the equipment must be calibrated specifically for organic temperature ranges, rather than general high-heat applications.

Making the Right Choice for Your Goal

To maximize the effectiveness of a tube furnace in PVT growth, align your process parameters with your specific material requirements.

- If your primary focus is Optical Quality: Prioritize the precision of the two-step heating program to maximize exciton oscillator strength and monolayer uniformity.

- If your primary focus is Crystal Size: Ensure the vacuum level and thermal gradient are optimized to allow for stable, long-distance transport to the hBN substrate.

Precision in the thermal profile is the single most critical factor in converting raw organic powder into high-performance optoelectronic monolayers.

Summary Table:

| Feature | Function in PVT Growth | Impact on J-Aggregate Crystals |

|---|---|---|

| Thermal Precision | Controlled sublimation at ~245°C | Prevents chemical decomposition |

| 2-Step Heating | Regulates vapor pressure ramping | Ensures uniform monolayer deposition |

| Vacuum Integration | Facilitates stable molecular transport | Minimizes contamination & improves purity |

| Zone Control | Manages substrate temperature (hBN) | Optimizes exciton oscillator strength |

Elevate Your Crystal Growth with KINTEK Precision

Achieving high-performance optoelectronic monolayers requires absolute thermal accuracy. KINTEK provides industry-leading Tube, Vacuum, and CVD systems specifically designed for the delicate sublimation requirements of organic J-aggregates. Our expert R&D and manufacturing teams offer customizable furnace solutions that ensure stable transport, precise two-step heating programs, and the vacuum integrity your research demands.

Ready to optimize your PVT growth process? Contact KINTEK Experts Today

Visual Guide

References

- Xinyi Zhao, Jianbin Xu. Monolayer J‐Aggregate Crystals Strong Coupling with an All‐Dielectric Metasurface for Photonic Properties Modification. DOI: 10.1002/lpor.202501208

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the hydrogen reduction process in a laboratory tube furnace facilitate the exsolution of nickel species?

- Why are sealed quartz tubes and gas control critical for TiO2 nanowire growth? Master Precision in Vapor-Phase Synthesis

- What materials are used for the tubes in drop tube furnaces and why? Choose the Right Tube for High-Temp Success

- What safety protections are included in three-zone split tube furnaces? Ensure Safe, Reliable High-Temp Operations

- How does a tube furnace ensure the quality of carbon materials? Precision Control for Hydrochar to Pyrochar Conversion

- What critical environmental conditions does a high-temperature tube furnace provide? Optimize CPOF-4/5 Cross-Linking

- What are the main industries where tube furnaces are used? Essential for Semiconductor, Battery, and Materials R&D

- Why is it important to calibrate the temperature profile of a tube furnace? Ensure Accurate and Repeatable Results