To ensure safe operation, three-zone split tube furnaces are engineered with a multi-layered system of protections. These include active alarms for overheat and thermocouple-break conditions, along with automatic shutdown systems for electrical faults like overcurrent or power failure. Safety interlocks and monitors for gas flow or pressure are also integrated to protect both the operator and the experimental integrity.

The core principle behind furnace safety is not a single feature, but a redundant system of active monitoring and passive safeguards. These systems work together to automatically prevent dangerous conditions before they can escalate, protecting the user, the sample, and the equipment itself.

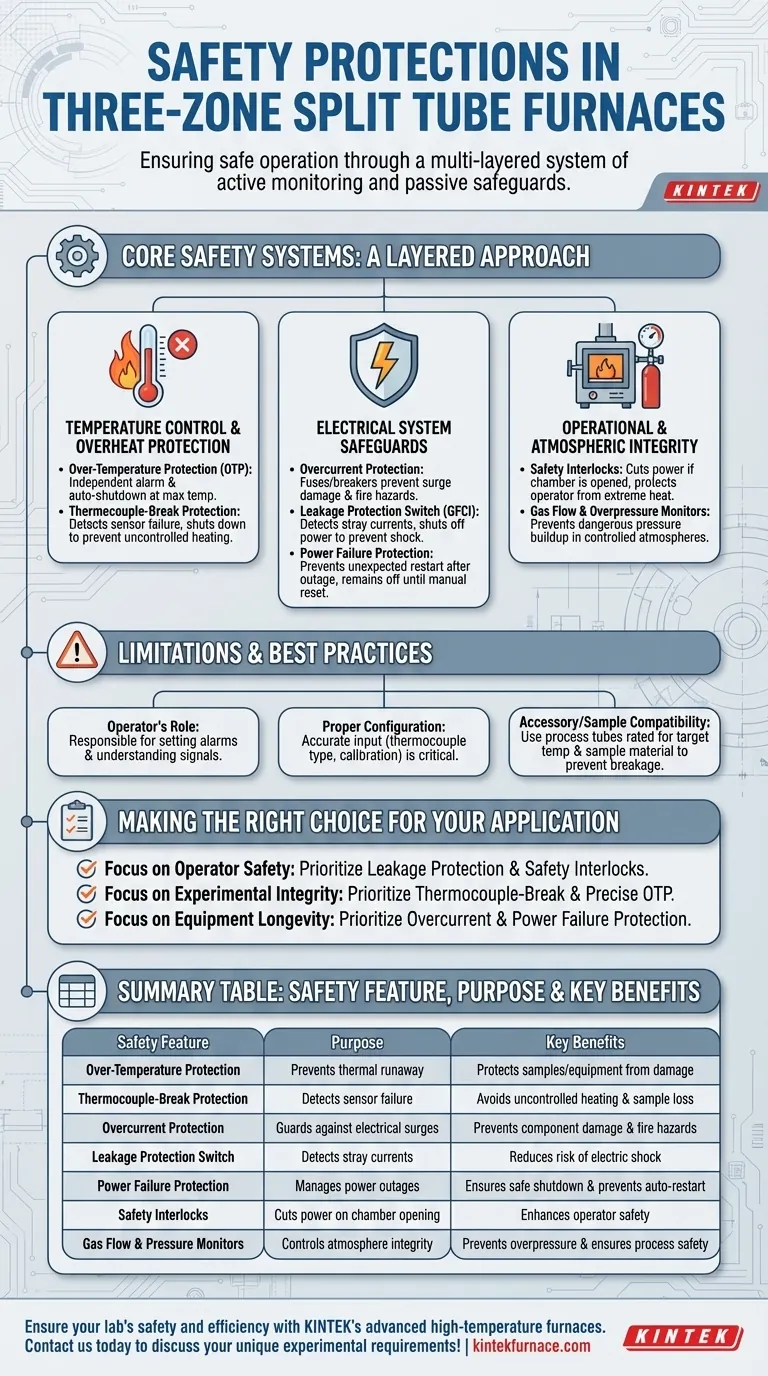

Core Safety Systems: A Layered Approach

Modern three-zone furnaces do not rely on a single point of failure. Instead, they integrate several independent systems that monitor thermal, electrical, and operational parameters simultaneously.

Temperature Control and Overheat Protection

This is the most critical safety function of any high-temperature furnace. It prevents thermal runaway, which can destroy the sample, damage the heating elements, and create a hazardous lab environment.

Key features include:

- Over-Temperature Protection (OTP): An independent controller or alarm system that automatically cuts power to the heating elements if the furnace exceeds a user-defined maximum temperature.

- Thermocouple-Break Protection: This system detects if a temperature-sensing thermocouple fails or becomes disconnected. It immediately shuts down the furnace to prevent the controller from applying uncontrolled, continuous power in a mistaken attempt to raise the temperature.

Electrical System Safeguards

These protections guard against electrical faults that could damage the furnace or pose a shock or fire hazard to operators.

- Overcurrent Protection: Fuses or circuit breakers prevent damage to internal components by interrupting power during an electrical surge or short circuit.

- Leakage Protection Switch: This device, also known as a Ground Fault Circuit Interrupter (GFCI), detects small stray currents and quickly shuts off power to prevent electric shock.

- Power Failure Protection: In the event of an external power outage, the system ensures the furnace does not restart unexpectedly when power is restored, remaining in a safe, powered-off state until manually reset.

Operational and Atmospheric Integrity

These features relate to the physical use of the furnace and the control of its internal atmosphere, which is critical for many advanced material processing applications.

- Safety Interlocks: These are physical switches that can be integrated into the furnace body. They automatically cut power to the heating elements if the furnace chamber is opened, protecting the user from exposure to extreme temperatures.

- Gas Flow & Overpressure Monitors: In furnaces used with controlled atmospheres, monitors and relief valves prevent the dangerous buildup of pressure from reactive gases, ensuring predictable and safe process conditions.

Understanding the Limitations and Best Practices

While robust, these safety systems are not a substitute for proper training and operational diligence. Understanding their limitations is key to maintaining a safe working environment.

The Critical Role of the Operator

Safety features are only effective when used correctly. The operator is responsible for setting appropriate alarm thresholds and understanding what each alarm signifies. An over-temperature alarm set too high offers no real protection.

Reliance on Proper Configuration

The furnace's protective systems rely on accurate input. Using the wrong type of thermocouple for your target temperature range or failing to properly calibrate controllers can render safety features ineffective.

Accessory and Sample Compatibility

The integrity of the process tube (e.g., quartz or alumina) is vital. Using a tube that is not rated for the target temperature or is incompatible with the sample material can lead to breakage, compromising the experiment and potentially damaging the furnace insulation and heating elements.

Making the Right Choice for Your Application

Understanding these systems allows you to align the furnace's capabilities with your primary goals.

- If your primary focus is operator safety: Prioritize furnaces with comprehensive electrical safeguards like leakage protection and well-implemented safety interlocks.

- If your primary focus is experimental integrity: The thermocouple-break and precise over-temperature protection are your most important features, as they prevent sample loss from thermal runaway.

- If your primary focus is equipment longevity: Overcurrent and power failure protection are crucial for protecting your investment from electrical damage.

Ultimately, a deep understanding of these integrated safety features empowers you to run experiments not just successfully, but also safely.

Summary Table:

| Safety Feature | Purpose | Key Benefits |

|---|---|---|

| Over-Temperature Protection | Prevents thermal runaway | Protects samples and equipment from damage |

| Thermocouple-Break Protection | Detects sensor failure | Avoids uncontrolled heating and sample loss |

| Overcurrent Protection | Guards against electrical surges | Prevents component damage and fire hazards |

| Leakage Protection Switch | Detects stray currents | Reduces risk of electric shock |

| Power Failure Protection | Manages power outages | Ensures safe shutdown and prevents auto-restart |

| Safety Interlocks | Cuts power on chamber opening | Enhances operator safety |

| Gas Flow & Pressure Monitors | Controls atmosphere integrity | Prevents overpressure and ensures process safety |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable solutions like Muffle, Tube, and Rotary Furnaces, as well as Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, ensuring optimal protection and performance. Contact us today to discuss how we can support your specific needs!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What is the maximum sample size that the 3-Zone tube furnace can accommodate? Optimize for Uniform Heating and CVD

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing