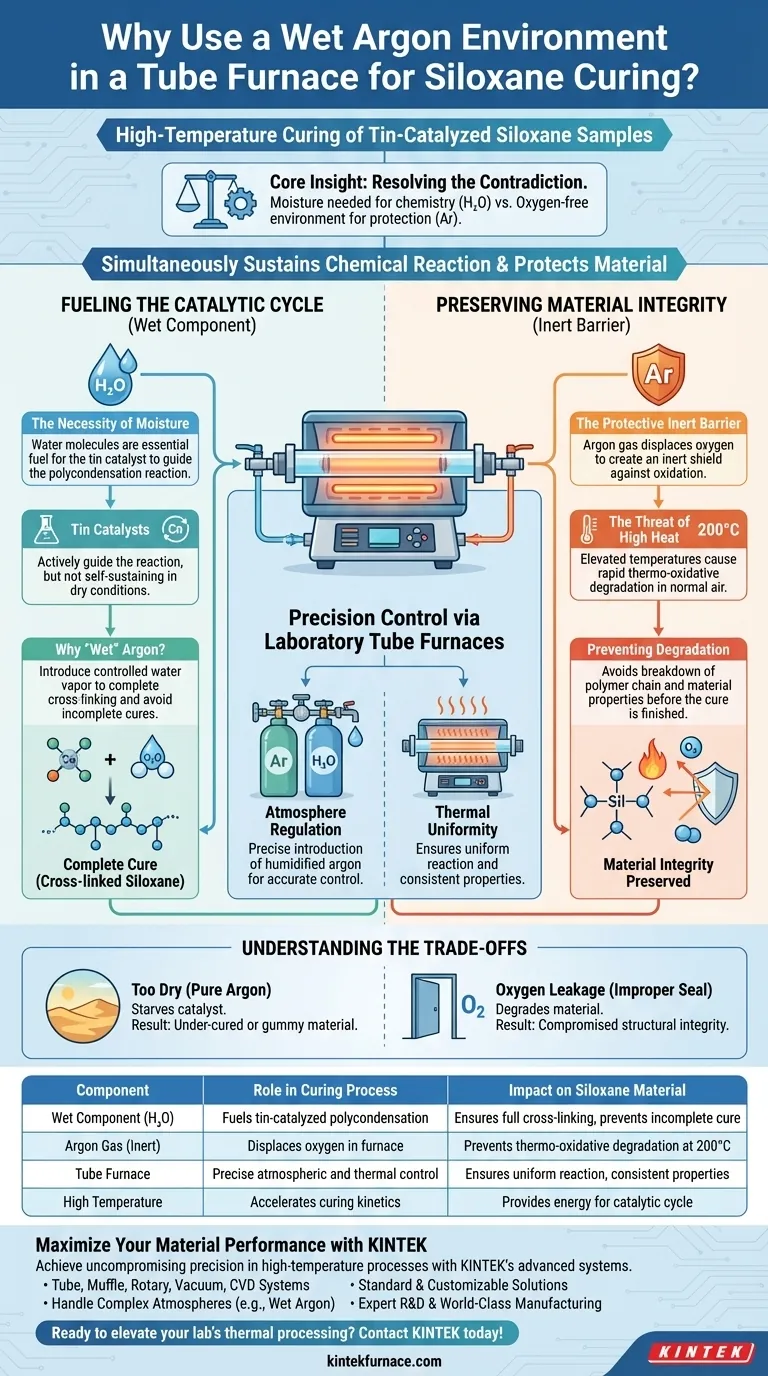

The primary purpose of using a wet argon environment in a laboratory tube furnace for this application is to simultaneously sustain the chemical reaction and protect the material. This setup provides the essential moisture required to drive the tin-catalyzed polycondensation reaction while creating an inert shield that prevents the siloxane from suffering thermo-oxidative degradation during high-temperature exposure (e.g., 200 °C).

Core Insight: Curing tin-catalyzed siloxanes presents a contradiction: the chemistry requires moisture to function, but the necessary high temperatures causes the material to degrade in normal air. A "wet argon" environment solves this by delivering the necessary water vapor for the catalyst within a protective, oxygen-free bubble.

Fueling the Catalytic Cycle

The Role of Tin Catalysts

Tin catalysts are not passive agents in siloxane chemistry; they actively guide the polycondensation reaction.

However, this specific catalytic cycle is not self-sustaining in a dry vacuum or dry gas.

The Necessity of Moisture

To keep the reaction moving, the catalyst requires the presence of water molecules.

Without an external source of moisture, the catalytic cycle halts, resulting in an incomplete cure.

Why "Wet" Argon?

The "wet" component of the gas stream is strictly functional.

It introduces a controlled amount of water vapor into the furnace tube, ensuring the tin catalyst has the fuel necessary to complete the cross-linking process.

Preserving Material Integrity

The Threat of High Heat

Effective curing for these materials often requires long-term treatment at elevated temperatures, such as 200 °C.

At these temperatures, standard atmospheric oxygen becomes destructive to siloxanes.

Preventing Thermo-Oxidative Degradation

Exposure to oxygen at high heat leads to rapid degradation of the polymer chain.

This results in a breakdown of material properties before the cure is even finished.

The Protective Inert Barrier

Argon is used because it is an inert gas.

By flooding the tube furnace with argon, you displace the oxygen, allowing the material to withstand the 200 °C heat needed for curing without chemically breaking down.

Precision Control via Tube Furnaces

Atmosphere Regulation

Tube furnaces are specifically engineered for operations requiring precise atmospheric control (Chemical Vapor Deposition, sintering, etc.).

They allow the user to introduce specific gas mixtures—in this case, humidified argon—with high accuracy.

Thermal Uniformity

Beyond the atmosphere, the tube furnace ensures consistent heat distribution.

This is critical for ensuring the polycondensation reaction occurs uniformly throughout the sample.

Understanding the Trade-offs

The Consequence of "Too Dry"

If you use pure, dry argon to maximize protection against oxidation, you will likely fail to achieve a cure.

The lack of moisture will starve the tin catalyst, leaving the siloxane under-cured or gummy.

The Consequence of Oxygen Leakage

Conversely, if the system is not properly sealed or the gas flow is insufficient, oxygen may enter the chamber.

Even with the correct moisture levels, the presence of oxygen at 200 °C will degrade the surface of the sample, compromising the structural integrity of the final product.

Making the Right Choice for Your Process

To achieve a high-quality cure, you must balance the introduction of moisture with the exclusion of oxygen.

- If your primary focus is Reaction Completion: Ensure your argon stream is actively humidified (wet) to prevent the tin catalyst from stalling during the process.

- If your primary focus is Material Stability: Verify that your tube furnace seals are intact and the inert gas flow is sufficient to prevent thermo-oxidative damage at 200 °C.

Summary: The wet argon environment is the critical bridge that allows you to satisfy the moisture requirements of the chemistry while bypassing the thermal limitations of the material.

Summary Table:

| Component | Role in Curing Process | Impact on Siloxane Material |

|---|---|---|

| Wet Component (H2O) | Fuels tin-catalyzed polycondensation | Ensures full cross-linking and prevents incomplete cure |

| Argon Gas (Inert) | Displaces oxygen in the furnace tube | Prevents thermo-oxidative degradation at high heat (200°C) |

| Tube Furnace | Precise atmospheric and thermal control | Ensures uniform reaction and consistent material properties |

| High Temperature | Accelerates the curing kinetics | Provides necessary energy for the catalytic cycle |

Maximize Your Material Performance with KINTEK

Achieve uncompromising precision in your high-temperature processes. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to handle complex atmospheric requirements like wet argon curing. Whether you need a standard setup or a fully customizable solution for your unique lab needs, our team is ready to support your innovation.

Ready to elevate your lab's thermal processing? Contact KINTEK today to consult with our experts!

Visual Guide

References

- Max Briesenick, Guido Kickelbick. Thermal Post-Cross-Linking of Siloxane/Silsesquioxane Hybrids with Polycyclic Aromatic Units for Tailored Softening Behavior in High-Temperature Applications. DOI: 10.3390/molecules30173532

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What factors influence the heating process in a tube furnace? Master Temperature Control and Efficiency

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What chemical role does a tubular furnace play during the carbonization of Si@Sn@C? Unlock Advanced Material Synthesis

- What role does a high-temperature tube furnace play in Mo2C synthesis? Master Carbonization Precision

- What auxiliary functions does a tube preheating furnace perform in flash sintering? Master Environmental Control

- Why use sealed vacuum tubes for perovskite supports? Achieve Superior Uniformity in Thin-Film Synthesis

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- How do you rejuvenate vacuum tubes? A Last-Resort Guide to Salvaging Rare Components