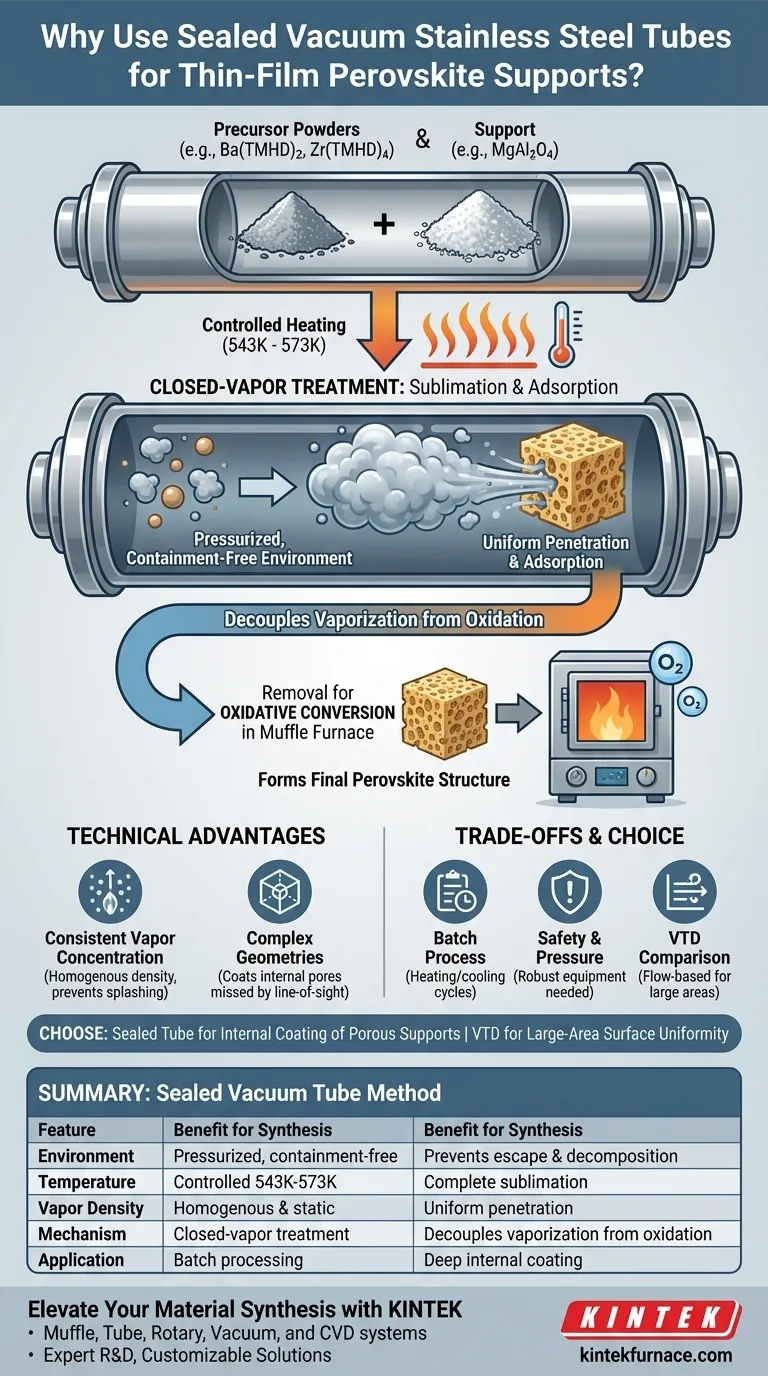

Processing supports and precursor powders within sealed vacuum stainless steel tubes creates a pressurized, containment-free environment essential for the complete sublimation of organic precursors. This specific configuration allows precursors, such as Ba(TMHD)2 and Zr(TMHD)4, to fully vaporize at temperatures between 543 K and 573 K without escaping, ensuring they uniformly penetrate and adsorb onto the support structure.

The core purpose of this "closed-vapor treatment" is to decouple vaporization from oxidation. By trapping high-density vapors in a sealed vessel, you force the precursor to coat every surface of the support—including internal pores—creating a uniform foundation for the final perovskite phase.

The Mechanics of Closed-Vapor Treatment

Facilitating Complete Vaporization

The primary challenge with organic precursors is ensuring they transition from solid to gas (sublimation) without decomposing or dispersing into the atmosphere.

Inside the sealed stainless steel tube, the controlled pressure environment suppresses premature decomposition. This allows the system to reach the necessary sublimation temperatures (543 K – 573 K) where the precursors can fully transition into a vapor phase.

Ensuring Uniform Adsorption

Once vaporized, the precursor molecules saturate the internal volume of the tube.

Because the system is closed, the vapor cannot escape and is forced to interact with the support material, such as MgAl2O4. This leads to deep, uniform penetration and adsorption onto the support surface, essentially "soaking" the support in precursor gas.

Preparing for Oxidative Conversion

The sealed tube process is strictly a deposition and adsorption stage.

It creates a necessary, uniform precursor layer that serves as the foundation for the next step. Once the adsorption is complete, the treated support is typically removed and processed in a muffle furnace for oxidative conversion, transforming the adsorbed layers into the final desired oxide or perovskite structure.

Technical Advantages of the Sealed System

Consistent Vapor Concentration

Unlike open systems where airflow can cause concentration gradients, a sealed tube maintains a homogenous vapor density.

This prevents the "splashing" or concentration fluctuations that can occur in flow-based systems. The static, high-pressure environment ensures that every part of the support is exposed to the same concentration of reactant.

Handling Complex Geometries

The pressurized nature of the sealed tube is particularly effective for porous or complex supports.

Vapor is forced into the microstructure of the support, coating internal surfaces that line-of-sight deposition methods might miss. This is critical for maximizing the active surface area of the final thin-film product.

Understanding the Trade-offs

Batch Processing vs. Continuous Flow

The sealed tube method is inherently a batch process. It requires sealing, heating, cooling, and unsealing for each run.

In contrast, Vapor Transport Deposition (VTD) methods—which often use crucibles with pressure-control apertures—are designed to release vapor steadily into a carrier gas flow. While the sealed tube offers superior saturation for porous supports, it may not be as suitable for continuous, large-area film deposition as flow-based systems.

Safety and Pressure Management

Sealing organic compounds in steel tubes and heating them generates significant internal pressure.

While necessary for the chemistry, this requires robust equipment (stainless steel) capable of withstanding these forces. It also demands careful temperature regulation to prevent over-pressurization, which could compromise the vessel integrity.

Making the Right Choice for Your Goal

When selecting a synthesis method for perovskite or oxide supports, consider your specific structural requirements.

- If your primary focus is internal coating of porous supports: Rely on the sealed vacuum tube method to ensure precursor vapors deeply penetrate and adsorb onto the support before oxidation.

- If your primary focus is large-area surface uniformity: Consider Vapor Transport Deposition (VTD) with flow-controlled apertures to maintain consistent layer thickness across a broad substrate.

Ultimately, the sealed tube is the superior choice when your priority is forcing a precursor to intimately bond with a complex support structure prior to chemical conversion.

Summary Table:

| Feature | Sealed Vacuum Tube Method | Benefit for Perovskite Synthesis |

|---|---|---|

| Environment | Pressurized, containment-free | Prevents precursor escape and premature decomposition |

| Temperature | Controlled 543 K – 573 K | Ensures complete sublimation of organic precursors |

| Vapor Density | Homogenous & static | Uniform penetration into complex or porous support structures |

| Mechanism | Closed-vapor treatment | Decouples vaporization from oxidation for precise deposition |

| Application | Batch processing | Ideal for deep internal coating of porous MgAl2O4 supports |

Elevate Your Material Synthesis with KINTEK

Precision in perovskite preparation requires high-performance equipment that can withstand rigorous thermal and pressure demands. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique research needs.

Whether you are performing closed-vapor treatment in stainless steel tubes or transitioning to oxidative conversion in a muffle furnace, our high-temperature systems provide the consistency and durability your lab deserves.

Ready to optimize your thin-film production? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Kai Shen, John M. Vohs. Enhanced Methane Steam Reforming Over Ni/BaZrO3. DOI: 10.1007/s10562-025-05087-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a tube reduction furnace simulate a blast furnace? Precision Testing for Metallurgical Performance

- What materials are used for the tubes in drop tube furnaces and why? Choose the Right Tube for High-Temp Success

- What is the primary role of a tube furnace in CuGaO2 treatment? Enhance Crystallization and Film Performance

- What is the function of a laboratory vacuum tube furnace in the solution treatment of Inconel X-750? Achieve Pure Microstructures

- How does multi-zone heating benefit the 70mm tube furnace? Unlock Precise Thermal Control for Advanced Materials

- What role does a horizontal tube furnace play in the carbonization of SiC-C preforms? Optimize Material Structural Yield

- How does a high-temperature tube furnace facilitate the final ceramization of EG/LTO composites? Expert Insights

- What role does a tubular furnace play in converting precursors into microwave-absorbing Fe-CN@CoCN? Expert Insights