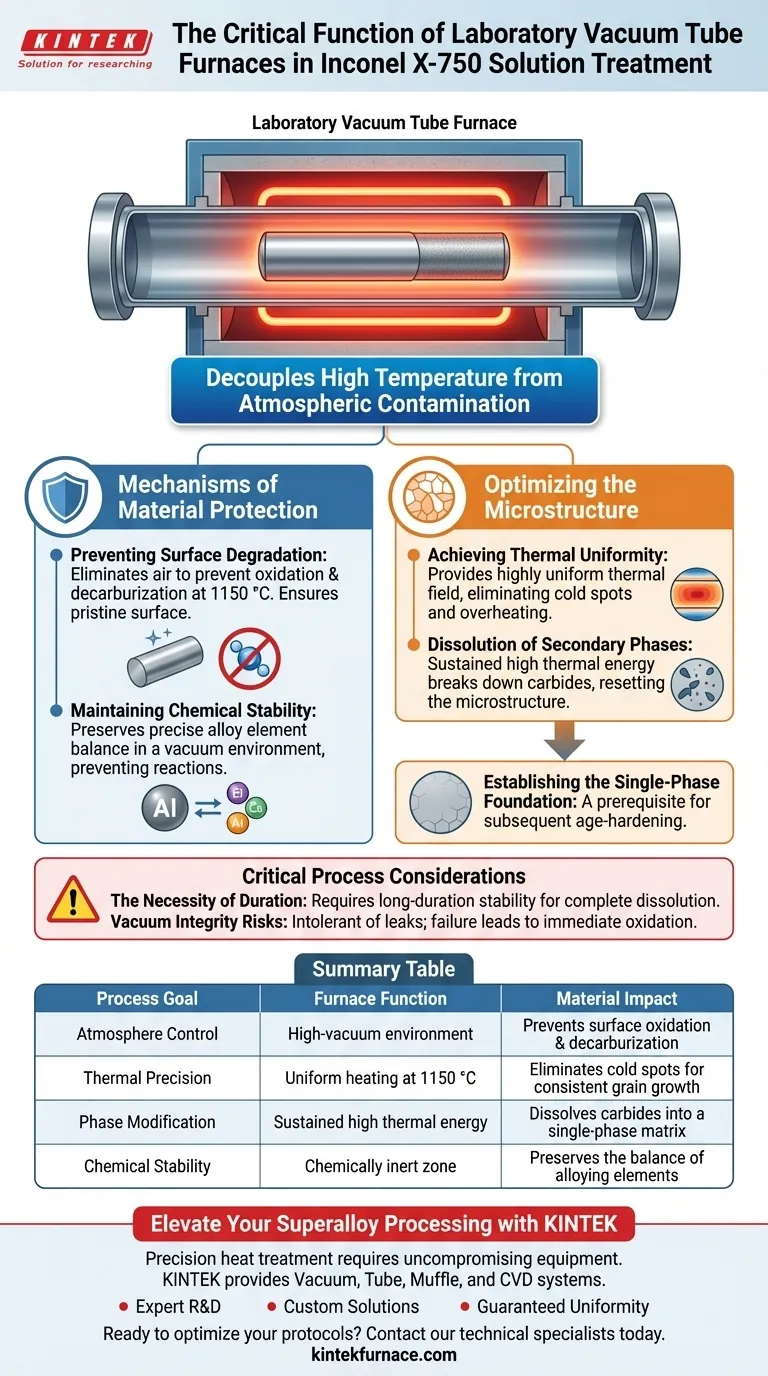

A laboratory vacuum tube furnace serves as a critical process control tool for the solution treatment of Inconel X-750, specifically designed to decouple high temperature from atmospheric contamination. Its primary function is to maintain a vacuum environment at temperatures around 1150 °C to prevent surface degradation while facilitating necessary microstructural changes.

The core value of this equipment is its ability to create a chemically inert, thermally uniform zone. This allows carbide phases to fully dissolve into the alloy matrix without the risk of oxidation, creating the essential "blank slate" required for subsequent hardening processes.

Mechanisms of Material Protection

Preventing Surface Degradation

At the high temperatures required for solution treatment (1150 °C), nickel-based superalloys are highly reactive to oxygen. The furnace utilizes a vacuum environment to remove air from the processing chamber.

By eliminating the atmosphere, the furnace actively prevents oxidation and decarburization. This ensures the material surface remains pristine even during long-duration treatment cycles.

Maintaining Chemical Stability

Inconel X-750 relies on a precise balance of alloying elements for its superalloy properties. Exposure to reactive gases could alter this chemical composition.

The vacuum environment preserves the chemical stability of these elements. It ensures they remain within the alloy rather than reacting with the environment, preserving the material's integrity.

Optimizing the Microstructure

Achieving Thermal Uniformity

Successful solution treatment requires that every part of the sample experiences the exact same temperature profile. The tube furnace design is engineered to provide a highly uniform thermal field.

This consistency eliminates cold spots or overheating. It ensures that the microstructural changes described below occur evenly throughout the entire cross-section of the component.

Dissolution of Secondary Phases

The primary metallurgical goal of this process is the modification of the alloy's internal structure. Specifically, phases such as carbides must be dissolved back into the primary matrix.

The furnace provides the sustained, high thermal energy required to break these phases down fully. This resets the microstructure of the alloy.

Establishing the Single-Phase Foundation

By dissolving carbides and homogenizing the structure, the furnace creates a uniform, single-phase organizational foundation.

This state is not the final product but a prerequisite. It prepares the Inconel X-750 for subsequent age-hardening, ensuring that future precipitation hardening occurs predictably and effectively.

Critical Process Considerations

The Necessity of Duration

The reference highlights that these solution treatments are "long-duration" processes. The furnace must be capable of maintaining stable conditions over extended periods.

Shortcuts in time often lead to incomplete dissolution of phases. The equipment must be robust enough to hold the vacuum and temperature steady until the microstructural conversion is complete.

Vacuum Integrity Risks

Because the process relies on the absence of atmosphere, the system is intolerant of leaks.

Any breach in vacuum integrity at 1150 °C will lead to immediate oxidation. The reliability of the furnace seals and pumps is as critical as the heating elements themselves.

Applying This to Your Heat Treatment Protocol

To maximize the effectiveness of your solution treatment for Inconel X-750, align your equipment settings with your specific metallurgical goals:

- If your primary focus is surface finish: rigorous vacuum maintenance is required to prevent decarburization and oxidation during the heating cycle.

- If your primary focus is mechanical uniformity: verify the furnace provides a strictly uniform thermal field to ensure complete dissolution of carbides across the entire part.

The vacuum tube furnace is not just a heater; it is a stability chamber that ensures the alloy is chemically and structurally prepared for high-performance applications.

Summary Table:

| Process Goal | Furnace Function | Material Impact |

|---|---|---|

| Atmosphere Control | High-vacuum environment | Prevents surface oxidation & decarburization |

| Thermal Precision | Uniform heating at 1150 °C | Eliminates cold spots for consistent grain growth |

| Phase Modification | Sustained high thermal energy | Dissolves carbides into a single-phase matrix |

| Chemical Stability | Chemically inert zone | Preserves the balance of alloying elements |

Elevate Your Superalloy Processing with KINTEK

Precision heat treatment of Inconel X-750 requires equipment that never compromises on thermal stability or vacuum integrity. KINTEK provides industry-leading laboratory high-temp furnaces—including Vacuum, Tube, Muffle, and CVD systems—engineered to deliver the exact conditions your materials demand.

Why partner with KINTEK?

- Expert R&D: Our systems are designed for high-performance metallurgy.

- Custom Solutions: Tailor tube dimensions and vacuum levels to your specific research needs.

- Guaranteed Uniformity: Ensure complete carbide dissolution with our superior heating element technology.

Ready to optimize your solution treatment protocols? Contact our technical specialists today to find the perfect customizable furnace for your laboratory.

Visual Guide

References

- Guilherme Maziero Volpato, Márcio C. Fredel. Influence of a Standard Heat Treatment on the Microstructure and Properties of Inconel X‐750 Produced by Laser Powder Bed Fusion. DOI: 10.1002/adem.202500306

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the function of an industrial-grade tube furnace? Mastering Expanded Graphite (EG) Calcination

- Why must air inlets be equipped with HEPA filters? Preventing Fiber Backflow in Split Tube Furnace Enclosures

- What are the common applications of a horizontal tube furnace? Unlock Precision in High-Temperature Processing

- Why are vacuum tube furnaces considered valuable in various fields? Unlock Precision in Material Processing

- Why is the vertical orientation of a drop tube furnace significant? Unlock Superior Process Control and Efficiency

- What critical conditions does a vacuum tube furnace provide for superconductor Tc measurement? Precision thermal control

- What is the purpose of using a tube resistance furnace with flowing oxygen for NMC synthesis? Achieve Pure Phase Purity

- What are the main advantages of an atmosphere tube furnace? Achieve Precise Control for Advanced Material Processing