The significance of a drop tube furnace’s vertical orientation lies in its use of gravity to control the movement of materials through the heating zone. This design enables processes that are difficult or impossible in a horizontal setup, such as rapid thermal processing of free-flowing particles or achieving exceptional temperature uniformity for sensitive applications.

The choice of a vertical furnace is not merely about saving space. It is a fundamental engineering decision to leverage gravity, enabling superior process control, higher material uniformity, and more efficient heating for specific applications involving material flow.

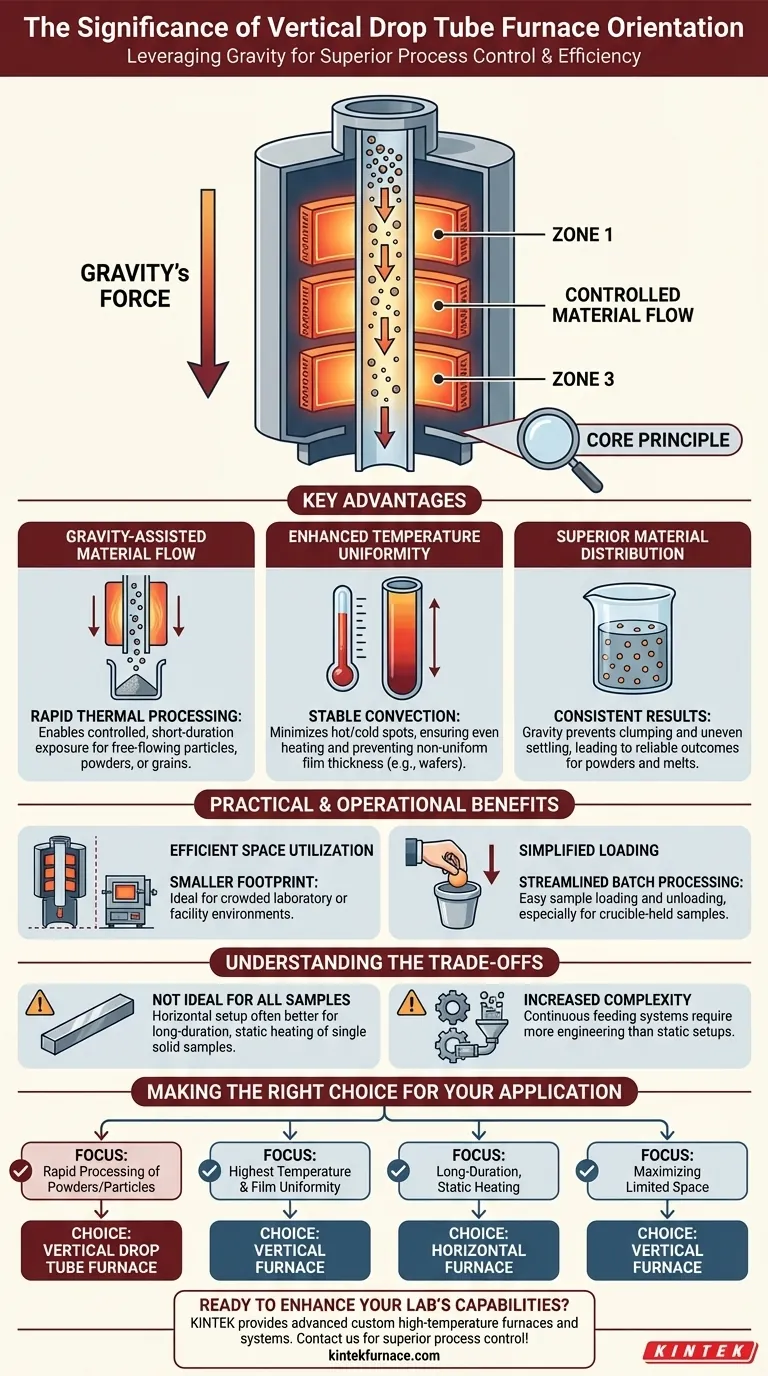

The Core Principle: Leveraging Gravity for Process Control

The primary advantage of a vertical tube furnace stems from its alignment with the force of gravity. This orientation fundamentally changes how materials are handled and heated.

Gravity-Assisted Material Flow

The most direct application is for processes that involve dropping or continuously feeding material through the furnace. Powders, grains, or other particulates can fall at a controlled rate through the heated tube.

This enables rapid thermal processing, where materials are exposed to high temperatures for a very short, controlled duration before being collected at the bottom.

Enhanced Temperature Uniformity

In a vertical tube, natural convection currents are more stable, leading to a more uniform temperature profile along the length of the tube. This minimizes hot or cold spots.

Unlike horizontal furnaces where samples can sag or rest on the bottom of the tube (creating a heat sink), a vertically suspended or free-falling sample is heated more evenly from all sides. This is critical for processes like semiconductor wafer manufacturing, where it helps prevent non-uniform film thicknesses.

Superior Material Distribution

For processes involving powders or melts, the vertical orientation ensures even material distribution. Gravity helps prevent the clumping or uneven settling that can occur in a horizontal tube, resulting in more consistent and reliable outcomes.

Practical and Operational Advantages

Beyond the core physics, the vertical design offers several practical benefits that make it the preferred choice in many laboratory and industrial settings.

Efficient Space Utilization

Vertical furnaces have a significantly smaller footprint compared to their horizontal counterparts. This makes them an ideal solution for crowded laboratories or facilities where floor space is at a premium.

Simplified Loading for Batch Processing

Loading and unloading samples, especially those held in crucibles, can be simpler. Samples can be lowered into and lifted out of the heating zone with ease, streamlining batch processing workflows.

Minimized Contamination

The downward flow of both the material and the purge gas in a vertical system helps carry away potential contaminants or byproducts. This design helps avoid issues like the particle generation that can be problematic in some horizontal furnace applications.

Understanding the Trade-offs

While powerful, a vertical orientation is not universally superior. The choice depends entirely on the process requirements.

Not Ideal for All Sample Types

If your process involves heating a single, static solid sample for a long duration (e.g., annealing a metal bar), a horizontal furnace is often simpler and more cost-effective. The benefits of gravity-assisted flow are irrelevant in this case.

Increased System Complexity

While loading a single sample can be easy, creating a system to continuously feed material at a precise rate can add mechanical complexity. The setup for dropping particles or pumping slurries requires more engineering than placing a sample boat in a horizontal tube.

The Impact of Heating Zones

Like all tube furnaces, vertical models can have single or multiple heating zones. A multi-zone furnace offers more precise control over the temperature gradient along the tube but comes at a higher cost and operational complexity. This choice must be matched to the specific thermal profile your process requires.

Making the Right Choice for Your Application

Selecting the correct furnace orientation requires a clear understanding of your primary experimental or production goal.

- If your primary focus is rapid thermal processing of powders or particles: A vertical drop tube furnace is the definitive choice to enable controlled, gravity-fed flow.

- If your primary focus is achieving the highest possible temperature and film uniformity: The vertical orientation is superior for eliminating temperature sinks and ensuring stable convection.

- If your primary focus is long-duration, static heating of a solid sample: A horizontal furnace is often the simpler, more direct, and more cost-effective tool.

- If your primary focus is maximizing limited laboratory space: The vertical furnace provides a clear advantage with its smaller footprint.

Understanding this fundamental design principle empowers you to select the precise tool that aligns with your process goals.

Summary Table:

| Aspect | Significance |

|---|---|

| Gravity-Assisted Flow | Enables controlled movement of materials for rapid thermal processing of particles. |

| Temperature Uniformity | Provides stable convection, minimizing hot/cold spots for sensitive applications. |

| Material Distribution | Prevents clumping and ensures even heating for consistent results. |

| Space Efficiency | Smaller footprint ideal for crowded laboratory environments. |

| Contamination Control | Downward flow helps carry away contaminants, reducing particle generation. |

Ready to enhance your lab's capabilities with a custom high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior process control and efficiency. Contact us today to discuss how our furnaces can optimize your thermal processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing