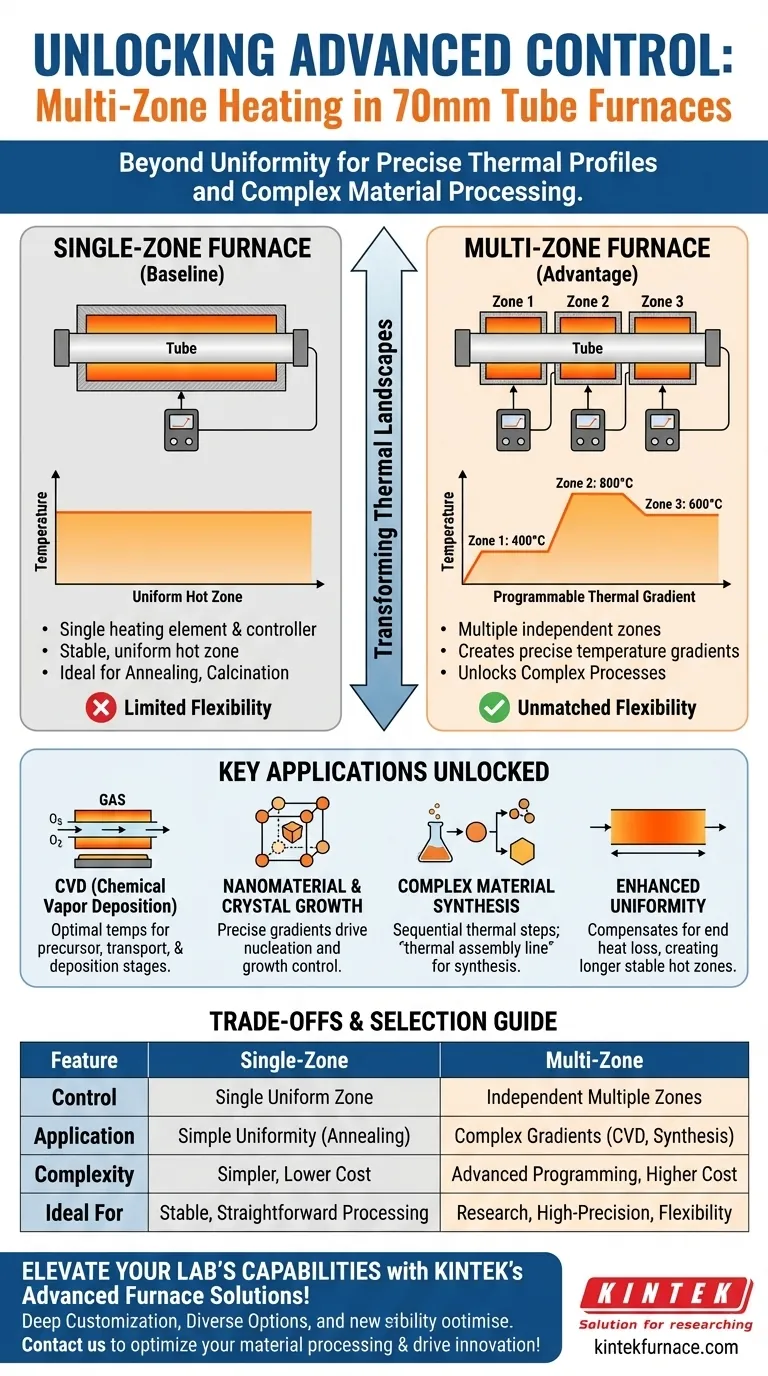

In a 70mm tube furnace, multi-zone heating provides advanced thermal control by allowing you to establish and maintain different temperatures in distinct sections along the tube's length. This capability moves beyond simple uniform heating, enabling the creation of precise temperature gradients and complex thermal profiles required for sophisticated material processing and scientific research.

While a single-zone furnace excels at creating one uniform hot zone, a multi-zone furnace transforms the tube into a programmable thermal landscape. This unlocks advanced processes like gradient heating and multi-stage synthesis that are difficult or impossible to achieve otherwise.

Beyond Uniformity: The Power of a Thermal Gradient

A standard tube furnace is valued for its ability to create a consistent, uniform temperature. Multi-zone technology fundamentally expands this capability.

The Single-Zone Baseline

A single-zone furnace has one set of heating elements and one controller. Its primary goal is to create a single, stable, and uniform hot zone in the center of the tube for processes like annealing or calcination.

The Multi-Zone Advantage

A multi-zone furnace divides the tube length into multiple, independently controlled heating sections (e.g., three zones). Each zone has its own thermocouple and controller, allowing you to set a unique temperature for each section.

This creates a deliberate thermal gradient, or temperature profile, along the tube. For example, you could set Zone 1 to 400°C, Zone 2 to 800°C, and Zone 3 to 600°C, creating a specific thermal landscape for your sample or process.

Key Applications Unlocked by Multi-Zone Control

The ability to create a thermal gradient is not just an enhancement; it is an enabling technology for specific, high-value applications.

Chemical Vapor Deposition (CVD)

Multi-zone control is critical for CVD. Different zones can be set to optimal temperatures for precursor vaporization, gas transport, and substrate deposition, all within a single, continuous process flow.

Nanomaterial and Crystal Growth

The synthesis of specific nanomaterials or the growth of crystals often relies on a precise temperature gradient. This gradient can drive the nucleation and growth process, giving you fine control over the final material structure.

Complex Material Synthesis

Many chemical reactions and material syntheses involve multiple steps that occur at different optimal temperatures. A multi-zone furnace allows a material to move through these temperature zones sequentially, like a thermal assembly line.

Enhanced Uniformity

Paradoxically, a multi-zone furnace can also create a longer and more precise uniform hot zone than a single-zone furnace. By slightly increasing the temperature in the outer zones, you can actively compensate for the natural heat loss that occurs at the ends of the tube, extending the area of thermal stability.

Understanding the Trade-offs

Choosing between a single-zone and a multi-zone furnace depends entirely on your process requirements and budget.

Single-Zone: Simplicity and Cost

For straightforward applications requiring one stable temperature, a single-zone furnace is simpler to operate, less complex to maintain, and has a lower initial cost.

Multi-Zone: Flexibility and Complexity

A multi-zone furnace represents a greater investment and adds a layer of programming complexity. However, it provides unmatched process flexibility, allowing you to perform a much wider range of thermal experiments.

Process Validation

Processes developed in a multi-zone furnace may be more difficult to scale to larger, single-zone industrial equipment. It requires careful consideration of how the thermal profile impacts the final product quality.

Making the Right Choice for Your Process

Your decision should be guided by the specific thermal requirements of your work, both now and in the future.

- If your primary focus is uniform annealing or calcination: A single-zone furnace is often the most cost-effective and straightforward solution.

- If your primary focus is chemical vapor deposition or complex synthesis: A multi-zone furnace is essential for controlling the distinct temperature stages of the process.

- If your primary focus is creating the largest possible uniform hot zone: A multi-zone furnace provides superior control to counteract heat loss at the ends of the tube.

- If your primary focus is studying materials across a temperature gradient: A multi-zone furnace is the only tool that can reliably create this specific thermal profile.

Ultimately, selecting a multi-zone furnace is an investment in process flexibility and precision.

Summary Table:

| Feature | Single-Zone Furnace | Multi-Zone Furnace |

|---|---|---|

| Temperature Control | Single uniform hot zone | Independent control of multiple zones |

| Applications | Annealing, calcination | CVD, nanomaterial growth, complex synthesis |

| Thermal Profile | Uniform heating | Custom gradients and extended uniformity |

| Complexity & Cost | Lower cost, simpler operation | Higher cost, advanced programming |

Elevate your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with customizable options like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for multi-zone heating or other complex thermal processes. Contact us today to discuss how we can optimize your material processing and drive innovation in your research!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What is the maximum sample size that the 3-Zone tube furnace can accommodate? Optimize for Uniform Heating and CVD

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients