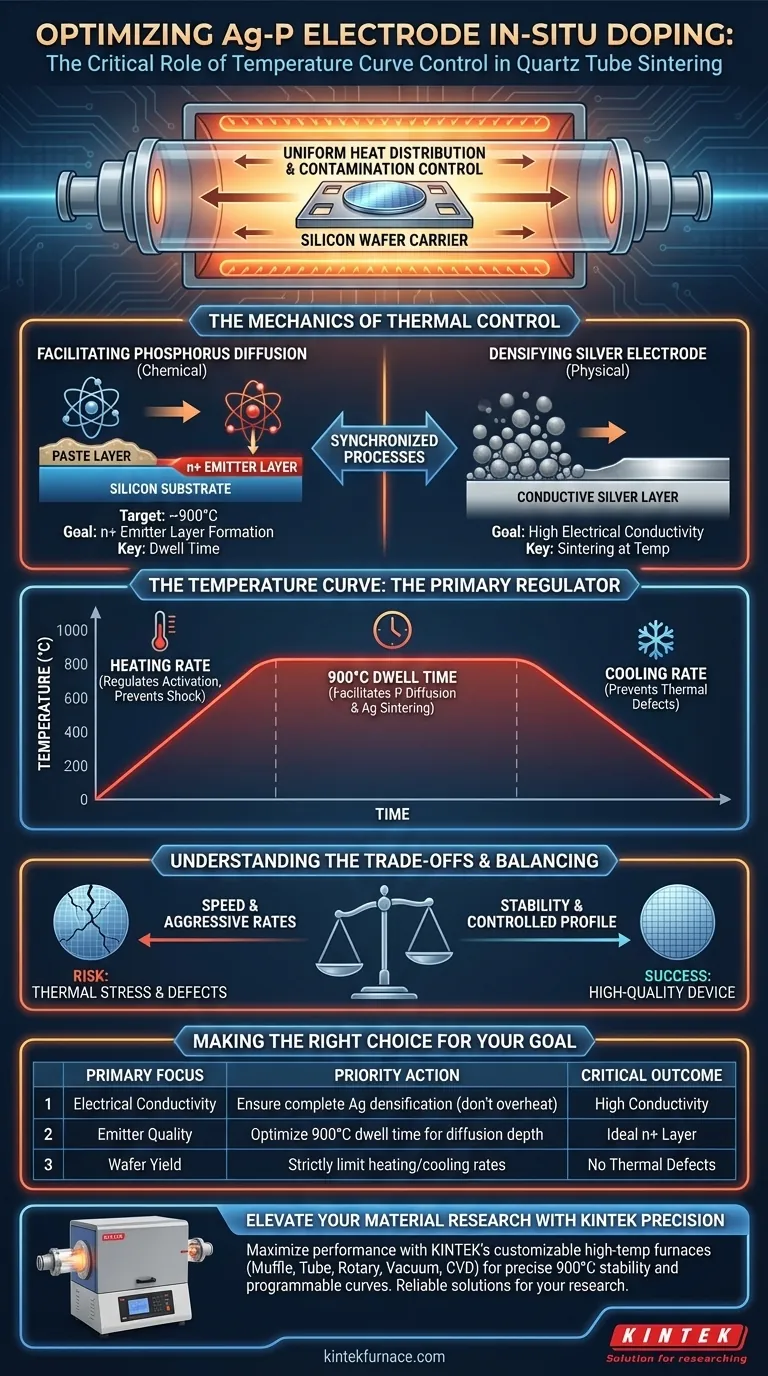

Precise temperature curve control determines the success of the in-situ doping process by regulating two simultaneous mechanisms: the diffusion of phosphorus into silicon and the densification of silver particles. In a quartz tube sintering furnace, the specific manipulation of heating rates, holding times at 900°C, and cooling rates allows for the creation of an effective n+ emitter layer without introducing thermal defects to the wafer.

The temperature profile acts as the primary regulator for activating phosphorus diffusion and densifying the electrode paste. Controlling this curve ensures the formation of a high-quality emitter layer while preserving the structural integrity of the silicon substrate.

The Mechanics of Thermal Control

Facilitating Phosphorus Diffusion

The primary objective of the heating phase is to drive phosphorus atoms from the electrode paste into the silicon substrate.

This process, known as in-situ doping, relies heavily on reaching and maintaining a specific target temperature, typically around 900°C.

Precise control ensures that the phosphorus penetrates the silicon to the correct depth to form an ideal n+ emitter layer.

Densifying the Silver Electrode

Simultaneously, the temperature curve drives the densification of silver particles within the paste.

This physical change is critical for establishing high conductivity in the electrode.

If the temperature is insufficient or the holding time too short, the silver may not sinter correctly, leading to poor electrical performance.

Preventing Thermal Defects

The cooling rate is just as critical as the heating rate.

A controlled reduction in temperature prevents the silicon wafer from experiencing thermal shock.

By managing the cooling curve, the furnace prevents the development of thermal defects that could compromise the mechanical and electrical integrity of the device.

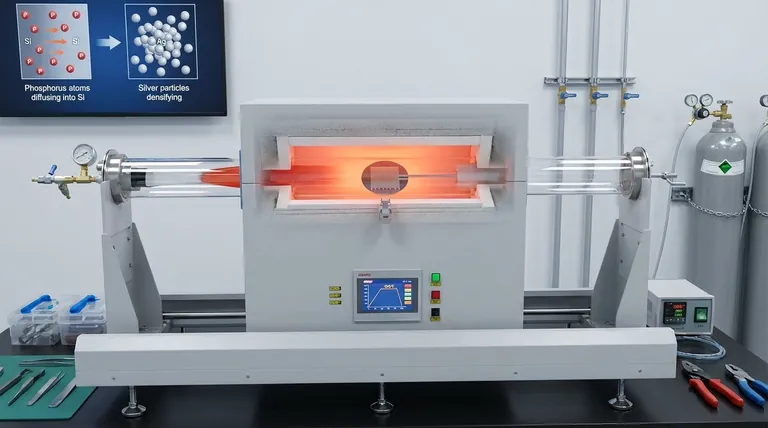

The Role of the Quartz Tube Environment

Precision at High Temperatures

Laboratory-grade quartz tube furnaces are specifically designed to maintain stability during the 900°C annealing process.

The quartz tube acts as a controlled environment that minimizes contamination while allowing for uniform heat distribution.

Regulating Process Variables

The furnace allows operators to program specific heating rates and holding times.

This programmability is essential because the diffusion rate of phosphorus is time-and-temperature dependent.

Operators can fine-tune these variables to synchronize the doping process with the sintering of the silver.

Understanding the Trade-offs

Balancing Diffusion and Sintering

There is a delicate balance between driving the phosphorus into the silicon and sintering the silver.

An overly aggressive heating curve might densify the silver quickly but fail to establish a deep enough n+ emitter layer.

Conversely, extending the holding time too long could result in excessive diffusion, altering the electrical characteristics of the junction.

Risks of Thermal Stress

Pushing for faster processing times by increasing heating or cooling rates introduces risk.

Rapid temperature changes can induce stress within the silicon crystal lattice.

This stress manifests as thermal defects, which defeat the purpose of the annealing process by lowering the overall quality of the wafer.

Making the Right Choice for Your Goal

To optimize the in-situ doping of Ag-P electrodes, you must prioritize the stability of the thermal profile over speed.

- If your primary focus is Electrical Conductivity: Prioritize a holding time that ensures complete densification of silver particles without overheating the substrate.

- If your primary focus is Emitter Quality: Optimize the 900°C dwell time to achieve the specific diffusion depth required for the n+ layer.

- If your primary focus is Wafer Yield: Strictly limit heating and cooling rates to prevent the formation of thermal defects in the silicon.

Success lies in synchronizing the physical sintering of the electrode with the chemical diffusion of the dopant through precise thermal management.

Summary Table:

| Parameter | Role in In-Situ Doping | Critical Outcome |

|---|---|---|

| Heating Rate | Regulates initial thermal activation | Prevents thermal shock to silicon wafer |

| 900°C Dwell Time | Facilitates phosphorus diffusion into Si | Formation of the n+ emitter layer |

| Silver Sintering | Physical densification of electrode paste | Establishes high electrical conductivity |

| Cooling Rate | Gradual temperature reduction | Prevents mechanical and thermal defects |

| Quartz Environment | Uniform heat & contamination control | Ensures purity and structural integrity |

Elevate Your Material Research with KINTEK Precision

Maximize the performance of your Ag-P electrodes with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique sintering and doping requirements. Whether you need precise 900°C temperature stability or programmable cooling curves to prevent thermal defects, our lab high-temp furnaces provide the reliability your research demands.

Ready to optimize your in-situ doping process? Contact us today to find your custom furnace solution.

Visual Guide

References

- Nurul Aqidah Mohd Sinin, Mohd Adib Ibrahim. Electrical performance for in-situ doping of phosphorous in silver paste screen-printed contact on p-type silicon solar cell. DOI: 10.61435/ijred.2025.60822

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a long-term annealing process in a tube furnace essential for Bi-Sb alloy? Achieve Material Homogeneity

- What advanced features can be found in more elaborate tube furnaces? Unlock Precision and Versatility for Demanding Applications

- How does a high-temperature tube furnace facilitate coal combustion simulation? Mastering Industrial R&D

- What role does a scissor lift play in the thermogravimetric analysis system of a tube furnace? Precision Alignment Guide

- What technical features make a laboratory horizontal tube furnace an ideal reaction device for oil sludge studies?

- Why is precise temperature control important in a tubular furnace? Ensure Material Consistency and Quality

- How do high-temperature redox cycles performed in a tube furnace contribute to the activation of Ni/BaZrO3 catalysts?

- How does the working temperature range affect the choice of a tube furnace? Match Your Lab's Thermal Needs for Precision and Cost-Efficiency