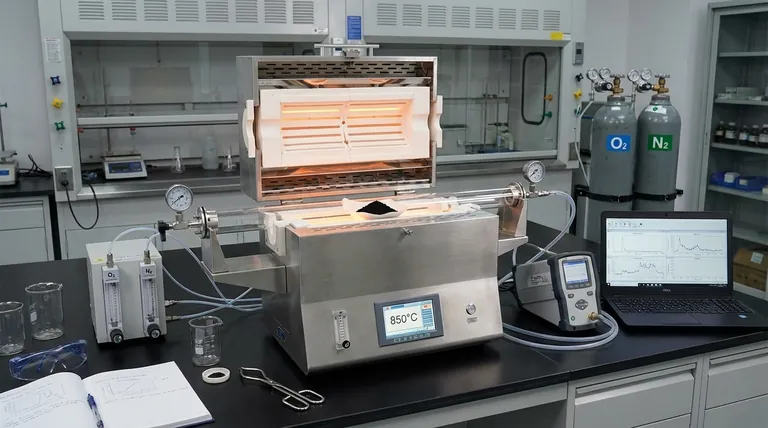

A high-temperature tube furnace acts as a precise thermal replicator, maintaining stable temperatures—such as 850°C—to strictly mimic the environment found within industrial boilers. By integrating this consistent heat source with a gas flow control system to regulate oxygen intake, the apparatus allows researchers to isolate and observe the complex combustion process in a controlled laboratory setting.

The tube furnace serves as a critical bridge between theoretical chemistry and industrial application. It provides the stability required to quantitatively analyze synergistic reactions, specifically for evaluating how effectively additives and catalysts can reduce pollutants like SO2 and NOx.

Creating a Controlled Thermal Environment

Replicating Industrial Conditions

The primary function of the tube furnace in this context is to simulate the actual combustion conditions of an industrial boiler.

By reaching and maintaining high temperatures, such as a steady 850°C, the furnace ensures that the coal samples experience the same thermal stress and energy potential as they would in a real-world power plant.

Ensuring Experimental Stability

In combustion research, temperature fluctuations can ruin data integrity.

The tube furnace provides a precisely controlled and constant thermal environment. This stability is required to ensure that any observed changes in combustion efficiency are due to the material properties, not environmental inconsistencies.

Facilitating Chemical Analysis

Regulating Oxidation

Combustion is fundamentally an oxidation reaction.

To simulate this accurately, the furnace is integrated with a gas flow control system. This allows researchers to introduce specific amounts of oxygen, enabling the precise study of how coal burns under different atmospheric conditions.

Studying Synergistic Reactions

Coal is rarely burned in isolation during advanced research; it is often tested alongside additives.

This setup allows researchers to quantitatively study the synergistic reactions between coal, various additives, and catalysts. Understanding these interactions is vital for optimizing combustion efficiency and catalytic performance.

Evaluating Environmental Impact

Quantifying Pollutant Removal

A major goal of modern coal research is reducing environmental harm.

The controlled environment of the tube furnace is essential for evaluating the removal efficiency of major pollutants. Researchers can measure exactly how well specific additives reduce sulfur dioxide (SO2) and nitrogen oxides (NOx) under high-temperature conditions.

Understanding the Trade-offs

Simulation vs. Reality

While a tube furnace offers precision, it operates on a laboratory scale.

It is excellent for studying chemical kinetics and thermodynamics, but it may not fully capture the complex fluid dynamics or physical scale of a massive industrial boiler.

Sensitivity to Setup

The accuracy of the data is heavily dependent on the gas flow integration.

If the oxygen introduction is not calibrated correctly, the simulation will fail to represent true combustion, leading to skewed data regarding pollutant removal efficiency.

Making the Right Choice for Your Research

To maximize the utility of a high-temperature tube furnace, align your experimental design with your specific data requirements.

- If your primary focus is reaction kinetics: Prioritize the precision of your gas flow control system to isolate how oxygen availability impacts combustion rates.

- If your primary focus is environmental compliance: Concentrate on the quantitative evaluation of additives to determine the exact ratios needed for maximum SO2 and NOx removal.

Precision in the lab leads to efficiency in the plant.

Summary Table:

| Feature | Function in Coal Combustion Research | Key Benefit |

|---|---|---|

| Temperature Control | Replicates industrial boiler environments (e.g., 850°C) | Ensures data integrity and thermal stability |

| Gas Flow Integration | Regulates oxygen intake and atmospheric conditions | Allows precise study of oxidation and kinetics |

| Additive Testing | Analyzes synergistic reactions with catalysts | Optimizes pollutant removal (SO2, NOx) |

| Controlled Environment | Isolates variables for quantitative chemical analysis | Bridges the gap between theory and application |

Elevate Your Combustion Research with KINTEK

Precision in the lab leads to efficiency in the plant. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of industrial simulation. Whether you are analyzing reaction kinetics or optimizing environmental compliance, our lab high-temperature furnaces are fully customizable for your unique research needs.

Ready to achieve superior thermal precision? Contact us today to find your custom furnace solution!

Visual Guide

References

- Shuqin Wang, Hao Fu. Study on the Synergistic Promotion of NOx Reduction in Coal Combustion by CaO and Cu-TiO<sub>2</sub>. DOI: 10.1051/e3sconf/202562801017

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of a dual-zone tube furnace for Ti3C2Tx MXene? Master Precise Sulfurization Kinetics

- What are the technical advantages of using a horizontal tube furnace for the slow pyrolysis of cotton stalks?

- How does a tube furnace achieve uniform thermal distribution? Master Precise Heat Control for Your Lab

- What are the key features of a vertical tube furnace? Maximize Efficiency in High-Temperature Labs

- What are the main characteristics of horizontal tube furnaces? Optimize Your High-Temp Processing with Uniform Heating

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How do horizontal furnaces support the ceramics industry? Boost Performance with Precision Heat Treatment

- How do resistance heating tube furnaces generate heat? Master Precise Temperature Control