At its core, a tube furnace achieves uniform thermal distribution through its fundamental design: cylindrical heating elements are arranged to encircle the process tube completely. This 360-degree heat source ensures that a sample inside the tube is subjected to a consistent thermal environment from all radial directions, a stark contrast to ovens that heat from the bottom or sides only.

The key to a tube furnace's thermal uniformity is not a single feature, but a system of design principles working in concert. It combines symmetrical heating geometry with precise, often multi-zoned, temperature control to create a stable and homogenous hot zone.

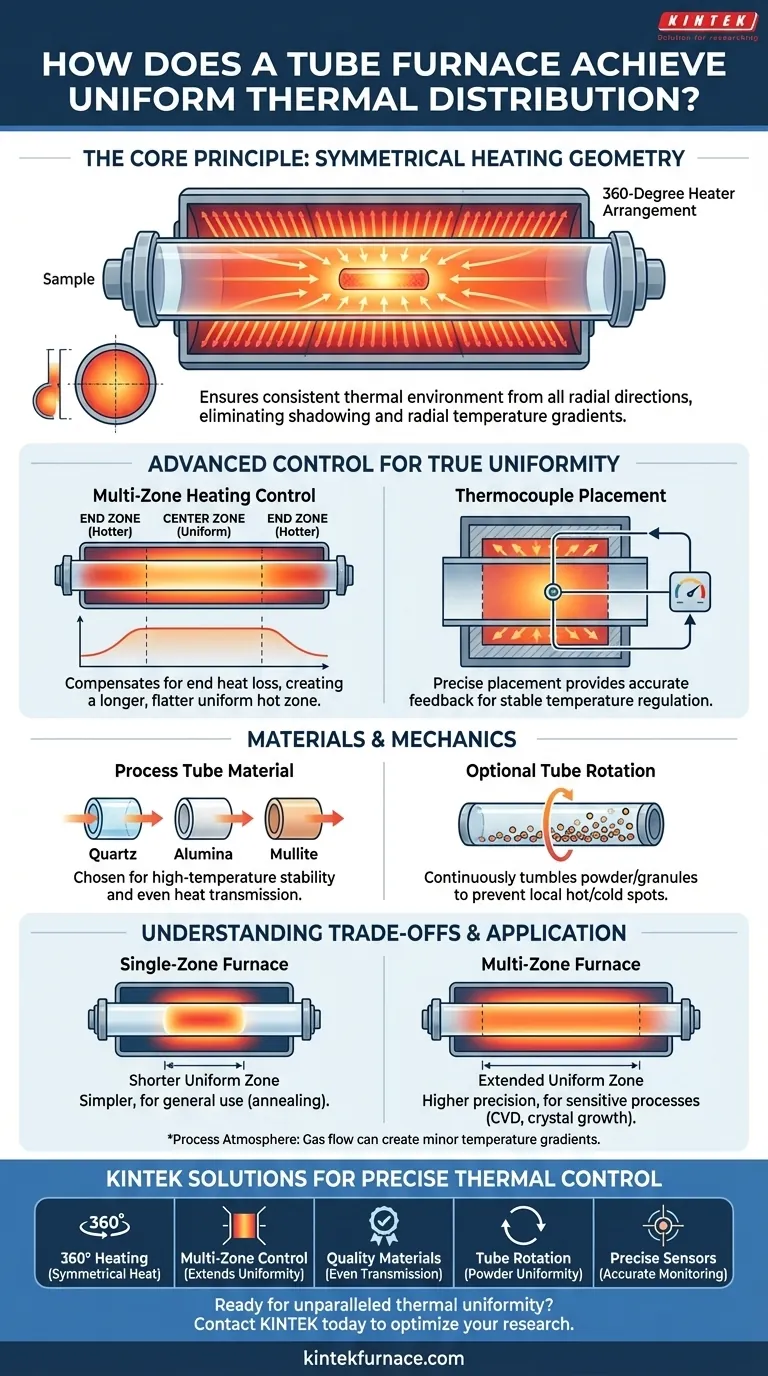

The Core Principle: Symmetrical Heating Geometry

A furnace's physical design is the foundation of its performance. The tube furnace excels by making heat delivery inherently symmetrical.

360-Degree Heater Arrangement

The primary mechanism is the arrangement of heating elements—like resistive wires or silicon carbide rods—in a cylinder around the process tube. This architecture ensures that thermal energy radiates inward evenly from all sides.

This eliminates the "shadowing" or one-sided heating common in other furnace designs, ensuring the entire circumference of the sample receives equal energy simultaneously.

Eliminating Radial Temperature Gradients

The goal of this design is to minimize or eliminate radial temperature gradients, which are temperature differences across the diameter of the tube.

By heating from all directions at once, the outer surface of a sample reaches the target temperature uniformly, allowing heat to conduct inward evenly. This is critical for consistent material transformations.

Advanced Control for True Uniformity

While geometry provides the foundation, active control systems are what deliver certifiable uniformity over a specific length of the furnace.

Multi-Zone Heating Control

Many high-performance tube furnaces are not one single heating unit, but are divided into multiple, independently controlled heating zones (typically three or more).

For example, a three-zone furnace has a center zone and two end zones. By setting the end zones to a slightly higher temperature, they can compensate for natural heat loss at the tube's openings. This creates a much longer, flatter, and more uniform temperature profile in the center zone where the sample is placed.

The Role of Thermocouple Placement

A control system can only manage what it can measure. Precise placement of thermocouples is essential for providing accurate feedback to the furnace's controller.

In a multi-zone furnace, each zone has at least one dedicated thermocouple. The controller constantly compares the measured temperature in each zone to the setpoint and adjusts the power to the heating elements accordingly, maintaining a stable and uniform thermal profile.

The Impact of Materials and Mechanics

Beyond heaters and controls, other physical properties and optional features contribute to the final result.

Process Tube Material

The material of the tube itself—often quartz, alumina, or mullite—plays a role. These materials are chosen for their high-temperature stability and their ability to transmit and distribute heat evenly.

A material like quartz, for instance, has good thermal conductivity and transparency to infrared radiation, which helps ensure the heat generated by the elements reaches the sample efficiently and uniformly.

Optional Tube Rotation and Tilting

For processing materials like powders or granules that don't conduct heat well, some furnaces incorporate mechanical rotation of the tube or tilting of the entire furnace body.

This motion continuously tumbles the material, ensuring every particle is exposed directly to the heated tube wall. This mechanical mixing prevents local hot or cold spots within the bulk material.

Understanding the Trade-offs

Perfect uniformity is an ideal. In practice, achieving it involves balancing cost, complexity, and physical limitations.

The "Uniform Zone" Limitation

A tube furnace's temperature is not uniform along its entire length. Heat is inevitably lost at the ends of the tube. Uniformity is specified over a central length known as the "uniform zone" or "hot zone."

Understanding the length of this zone and ensuring your sample fits entirely within it is critical for achieving repeatable results.

Single-Zone vs. Multi-Zone

A single-zone furnace is simpler and less expensive but has a shorter uniform zone relative to its total heated length. A multi-zone furnace offers a significantly longer and more precise uniform zone but at a higher cost and complexity.

The choice depends entirely on the precision your process requires and the size of your sample.

Process Atmosphere and Flow Rate

Introducing a process gas, whether for inert atmosphere or chemical vapor deposition (CVD), can disturb thermal uniformity. The gas flow can carry heat, creating a slight temperature gradient along the direction of flow. This effect is typically minor but must be considered for highly sensitive processes.

Making the Right Choice for Your Goal

Understanding these principles allows you to select and operate a tube furnace effectively. Your application dictates the necessary level of uniformity.

- If your primary focus is maximum precision for sensitive processes (CVD, crystal growth, or advanced materials synthesis): You must use a multi-zone furnace to create a highly stable and extended uniform hot zone.

- If your primary focus is general-purpose heat treatment (annealing or sintering): A well-designed single-zone furnace is often sufficient, provided you carefully place the sample in the center of the hot zone.

- If your primary focus is processing powders or non-conductive granular materials: A furnace with tube rotation capabilities is essential to ensure all material is heated evenly.

By matching the furnace's capabilities to your process needs, you gain precise control over your material's thermal environment.

Summary Table:

| Feature | Role in Uniform Thermal Distribution |

|---|---|

| 360-Degree Heating | Provides symmetrical heat from all radial directions |

| Multi-Zone Control | Compensates for heat loss, extends uniform hot zone |

| Process Tube Materials | Ensures even heat transmission and stability |

| Optional Tube Rotation | Prevents hot/cold spots in powders or granules |

| Thermocouple Placement | Enables precise temperature monitoring and adjustment |

Ready to achieve unparalleled thermal uniformity in your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in materials synthesis, heat treatment, or powder processing, we can help you optimize your thermal processes for consistent, reliable results. Contact us today to discuss how our furnaces can elevate your research and development!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab