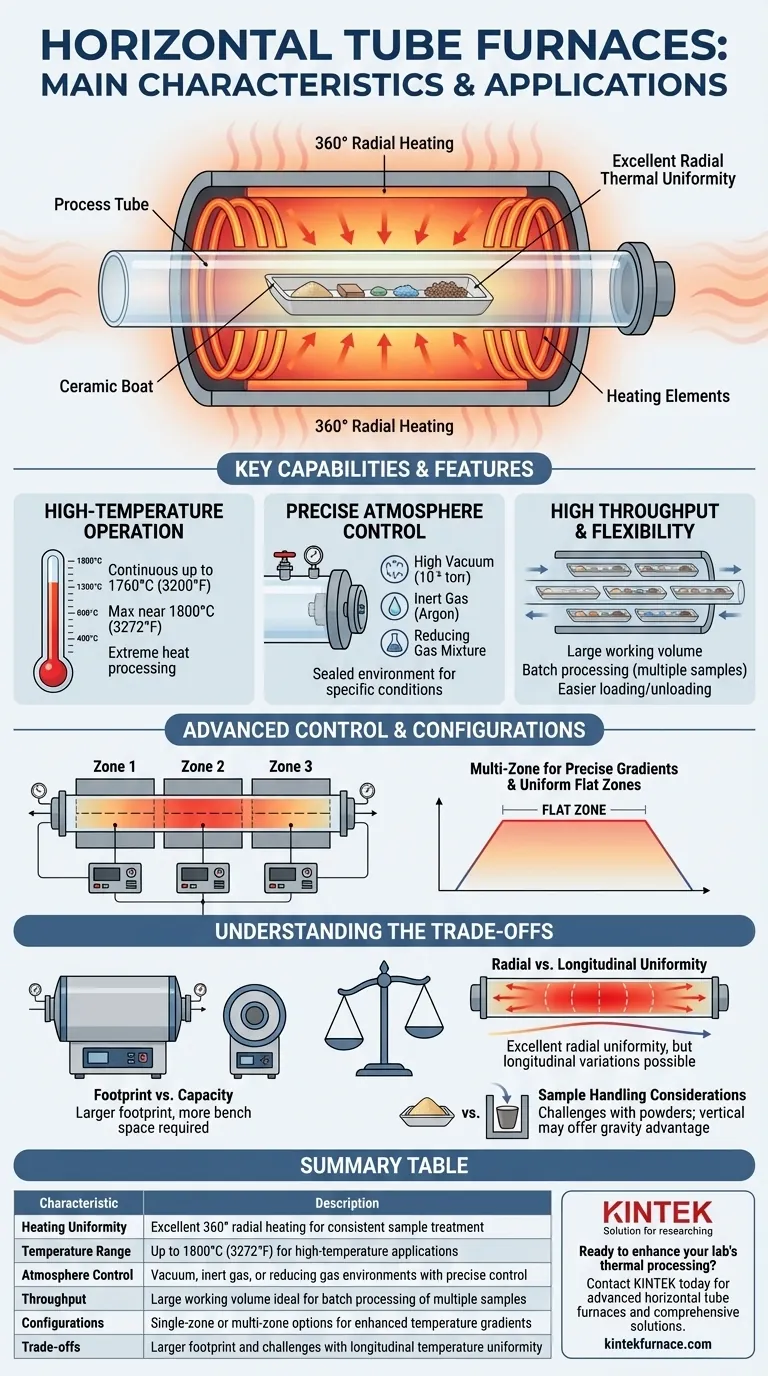

At its core, a horizontal tube furnace is a high-temperature chamber designed for thermal processing where the sample tube is oriented horizontally. Its primary characteristics are its ability to provide exceptional 360-degree heating uniformity around the sample, a large working volume suitable for batch processing, and precise control over the internal atmosphere. These furnaces are workhorses in materials science, chemistry, and engineering labs.

The defining characteristic of a horizontal tube furnace is its design for excellent radial heat distribution and high-throughput capacity. However, this design introduces practical trade-offs in physical footprint and the need for careful management of temperature gradients along the tube's length.

The Core Design Principle: Uniform Radial Heating

The horizontal furnace's entire design revolves around delivering consistent, stable heat to a sample from all sides.

How Horizontal Orientation Works

A sample, often held in a ceramic or quartz "boat," is slid into a central process tube. This tube is surrounded by high-performance heating elements.

When activated, these elements radiate heat inward, enveloping the process tube and the sample within it.

The Goal of Radial Uniformity

The key benefit of this design is outstanding radial thermal uniformity. Because heat is applied across the full 360-degree axis of the tube, the sample receives incredibly even heating from all sides.

This is critical for processes where consistent material properties are the primary goal, preventing hot or cold spots on the sample's surface.

Multi-Zone Configurations for Precision

To further refine temperature control, many horizontal furnaces are available in single-zone or multi-zone configurations.

A multi-zone furnace uses separate controllers for different sections of the heating elements. This allows you to create precise temperature gradients or ensure an exceptionally uniform flat zone along a greater length of the tube.

Key Capabilities and Features

Beyond its basic design, several features define the modern horizontal tube furnace.

High-Temperature Operation

These furnaces are built for extreme heat, with some models capable of sustaining continuous operating temperatures up to 1760°C (3200°F) and reaching maximums near 1800°C (3272°F).

Precise Atmosphere Control

The sealed nature of the process tube is ideal for atmosphere control. With the right end caps and systems, you can perform heating under specific conditions.

This includes running processes under a high vacuum (down to 10⁻⁵ torr), in an inert gas like argon to prevent oxidation, or with a reducing gas mixture. Optional mass flow controllers allow for precise, programmable gas mixing.

High Throughput and Flexibility

The horizontal orientation provides a larger effective working volume. This makes them ideal for processing larger individual samples or multiple smaller samples at once in a batch process.

Their design, sometimes featuring a sliding mechanism, facilitates easier loading and unloading for both batch and continuous production workflows.

Understanding the Trade-offs

No design is without its compromises. Understanding the limitations of a horizontal furnace is key to using it effectively.

Footprint vs. Capacity

The primary drawback is physical size. A horizontal tube furnace has a larger footprint and requires more bench space than its vertical counterpart to achieve the same heated length.

The Challenge of Longitudinal Uniformity

While radial (360-degree) uniformity is excellent, achieving perfect temperature uniformity along the entire length of the tube can be a challenge.

Natural convection can cause slight temperature variations from the center to the ends. This is why multi-zone models are often necessary for applications demanding the highest level of lengthwise uniformity.

Sample Handling Considerations

Manipulating samples inside a long, horizontal tube can be more difficult than simply dropping a crucible into a vertical furnace.

This is especially true for powders, which require a container or boat, whereas in a vertical furnace gravity can be used to your advantage.

Making the Right Choice for Your Process

Selecting the right furnace depends entirely on your specific experimental or production goals.

- If your primary focus is processing large or numerous samples: The high capacity and ease of batch loading make the horizontal furnace an excellent choice.

- If your primary focus is absolute thermal uniformity: A multi-zone horizontal furnace provides superior radial heating and the control needed to flatten the temperature profile along the tube's length.

- If your primary focus is advanced material synthesis: The outstanding atmosphere control capabilities (vacuum, inert gas) are a critical advantage for sensitive processes.

- If your primary focus is simplicity with loose powders or melts: Consider if a vertical furnace might offer more convenient, gravity-assisted handling for your specific sample type.

By understanding these core characteristics and trade-offs, you can confidently select the precise thermal processing tool your work demands.

Summary Table:

| Characteristic | Description |

|---|---|

| Heating Uniformity | Excellent 360° radial heating for consistent sample treatment |

| Temperature Range | Up to 1800°C (3272°F) for high-temperature applications |

| Atmosphere Control | Vacuum, inert gas, or reducing gas environments with precise control |

| Throughput | Large working volume ideal for batch processing of multiple samples |

| Configurations | Single-zone or multi-zone options for enhanced temperature gradients |

| Trade-offs | Larger footprint and challenges with longitudinal temperature uniformity |

Ready to enhance your lab's thermal processing? Contact KINTEK today to discover how our advanced horizontal tube furnaces—part of our comprehensive line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—can be customized to meet your unique experimental needs. With exceptional R&D and in-house manufacturing, we deliver precise, high-performance solutions for materials science, chemistry, and engineering applications. Get in touch now to discuss your requirements and boost your efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety