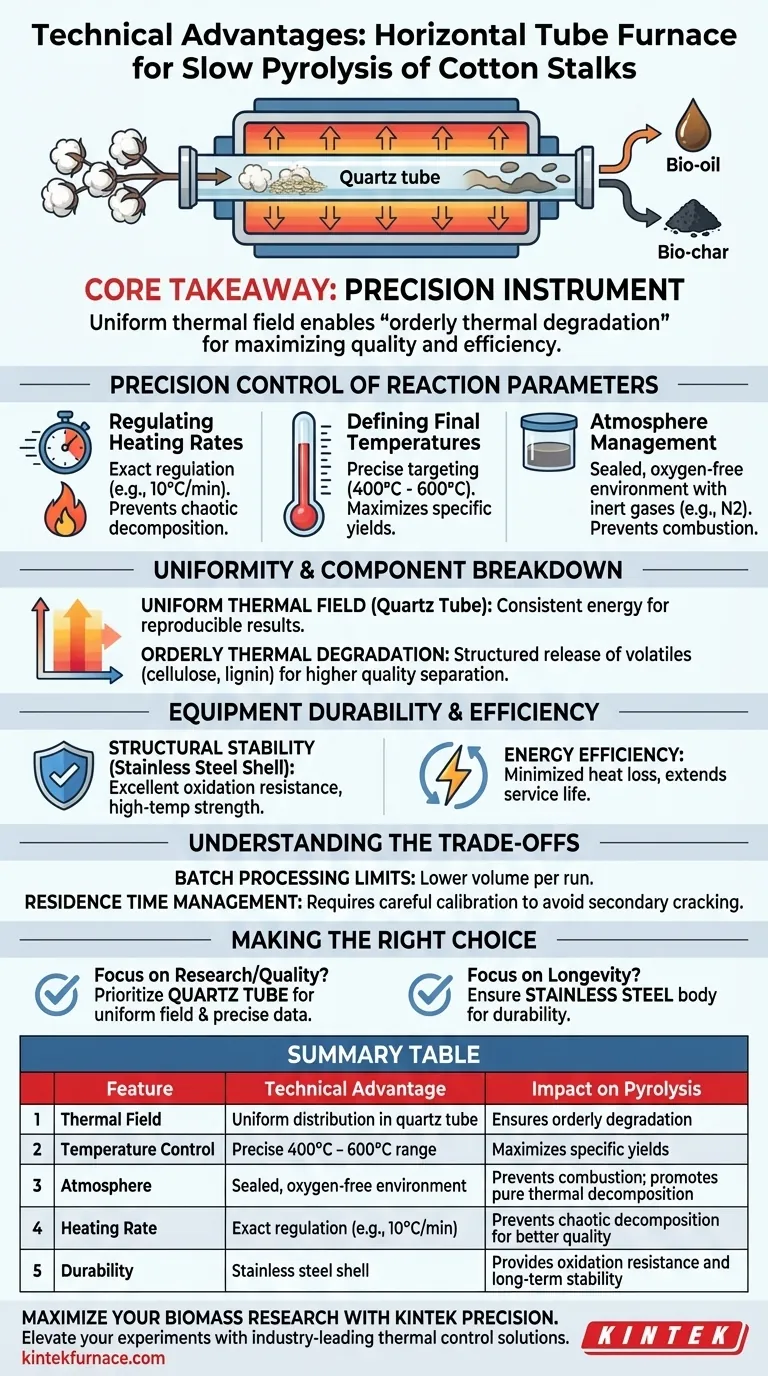

The primary technical advantage of using a horizontal tube furnace for the slow pyrolysis of cotton stalks is the ability to maintain a strictly controlled, oxygen-free environment with a uniform thermal field. This specific configuration allows for the precise regulation of heating rates (e.g., 10°C per minute) and final temperatures between 400°C and 600°C, ensuring the efficient and orderly decomposition of biomass components.

Core Takeaway The horizontal tube furnace acts as a precision instrument rather than a blunt heating tool; its uniform thermal field enables the "orderly thermal degradation" of complex biomass structures like cellulose and lignin. This control is the deciding factor in maximizing the quality and collection efficiency of bio-oil and bio-char.

Precision Control of Reaction Parameters

Regulating Heating Rates

The success of slow pyrolysis hinges on the rate at which thermal energy is applied. Horizontal tube furnaces allow for exact heating rate regulation, such as the 10°C per minute standard often used for cotton stalks.

Controlled heating prevents rapid, chaotic decomposition. This ensures that the biomass spends the optimal amount of time in specific temperature zones, facilitating the desired chemical changes.

Defining Final Temperatures

You can precisely target final pyrolysis temperatures, typically between 400°C and 600°C.

This range is critical for cotton stalks. It maximizes the yield of specific byproducts, balancing the ratio of solid bio-char to liquid bio-oil based on your specific requirements.

Atmosphere Management

The furnace design supports a sealed, oxygen-free environment.

By introducing inert gases like Nitrogen ($N_2$) or reactive gases like $CO_2$, you prevent combustion. This directs the chemical process strictly toward pyrolysis (thermal decomposition) rather than burning the feedstock.

Uniformity and Component Breakdown

The Uniform Thermal Field

The central reaction vessel, often a quartz tube, creates a uniform thermal field.

Unlike systems with hot spots or uneven heating, a horizontal tube ensures that the entire sample of cotton stalks receives consistent thermal energy. This consistency is vital for reproducible experimental results.

Orderly Thermal Degradation

Cotton stalks are composed of cellulose, hemicellulose, and lignin, which decompose at different temperatures.

The uniform heat allows for the orderly degradation of these components. Instead of a simultaneous, uncontrolled breakdown, the furnace facilitates a structured release of volatiles, leading to higher quality separation of bio-oil and char.

Equipment Durability and Efficiency

Structural Stability

While the reaction vessel may be quartz, the furnace body often utilizes stainless steel for the shell.

This material provides excellent oxidation resistance and high-temperature strength. It ensures the equipment maintains its shape and integrity during the prolonged heating cycles required for slow pyrolysis.

Energy Efficiency

The design minimizes heat loss to the surrounding environment.

By retaining heat effectively, the furnace ensures that the energy input is directed primarily at the reaction vessel. This maintains the stability of the temperature field and extends the service life of the heating elements.

Understanding the Trade-offs

Batch Processing Limits

Horizontal tube furnaces are typically designed for batch processing rather than continuous throughput.

While excellent for research and high-quality production, this design limits the volume of cotton stalks you can process in a single run compared to continuous fluidized bed reactors.

Residence Time Management

Achieving the perfect bio-oil yield requires strict management of residence time.

If the volatile gases remain in the hot zone too long, they may undergo secondary cracking (breaking down further into non-condensable gases). While some furnaces allow for multi-zone control to manage this, it requires careful calibration to avoid diminishing your bio-oil yield.

Making the Right Choice for Your Goal

To determine if this setup is right for your cotton stalk pyrolysis project, consider your primary objective:

- If your primary focus is Research and Product Quality: Prioritize the quartz tube configuration to ensure the most uniform thermal field and precise data regarding the orderly degradation of cellulose and lignin.

- If your primary focus is Equipment Longevity: Ensure the furnace body utilizes high-grade stainless steel to resist oxidation and deformation during repeated high-temperature cycles.

Precision in the heating process is the single greatest predictor of quality in bio-oil and bio-char production.

Summary Table:

| Feature | Technical Advantage | Impact on Pyrolysis |

|---|---|---|

| Thermal Field | Uniform distribution in quartz tube | Ensures orderly degradation of cellulose/lignin |

| Temperature Control | Precise 400°C - 600°C range | Maximizes specific yields of bio-oil and bio-char |

| Atmosphere | Sealed, oxygen-free environment | Prevents combustion; promotes pure thermal decomposition |

| Heating Rate | Exact regulation (e.g., 10°C/min) | Prevents chaotic decomposition for better product quality |

| Durability | Stainless steel shell | Provides oxidation resistance and long-term stability |

Maximize Your Biomass Research with KINTEK Precision

Elevate your pyrolysis experiments with industry-leading thermal control. KINTEK provides expert-engineered solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific research parameters. Our furnaces ensure the uniform thermal fields and precise atmosphere management necessary for high-quality bio-oil and bio-char production.

Ready to optimize your lab's performance? Contact KINTEK today for a customized consultation

Visual Guide

References

- Hussien Elshareef, Yuguang Zhou. Investigation of Bio-Oil and Biochar Derived from Cotton Stalk Pyrolysis: Effect of Different Reaction Conditions. DOI: 10.3390/resources14050075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the primary purpose of utilizing a tubular furnace for zeolite calcination? Achieve Precise Deammoniation

- How do split tube furnaces provide access to the chamber? Unlock Easy Sample Handling for Your Lab

- What is the importance of the nitrogen displacement step in a Tube Furnace? Secure High-Performance Ru-1 Catalysts

- How does tube material affect furnace performance? Choose the Right Material for Optimal Results

- What is the function of quartz vacuum encapsulation in RhSeCl CVT? Mastering Pure Crystal Growth

- What are some examples of tube furnace models and their ideal applications? Find Your Perfect Match for Precise Thermal Processing

- What core task does a tubular vacuum sintering furnace perform? Optimizing Confined Carbon Chain Synthesis

- What is the function of a phosphorus diffusion tube furnace? Creating MoS2/Si Heterojunctions with Precision