At its core, a split tube furnace provides access to its internal chamber through a simple but highly effective hinge mechanism. The main body of the furnace is constructed in two separate halves, allowing it to be opened and closed like a clamshell around a work tube.

The critical advantage of a split tube furnace isn't just about accessing the chamber—it's about the ability to place a fully assembled, sealed, or complex sample apparatus directly into the heating zone without sliding it in from one end.

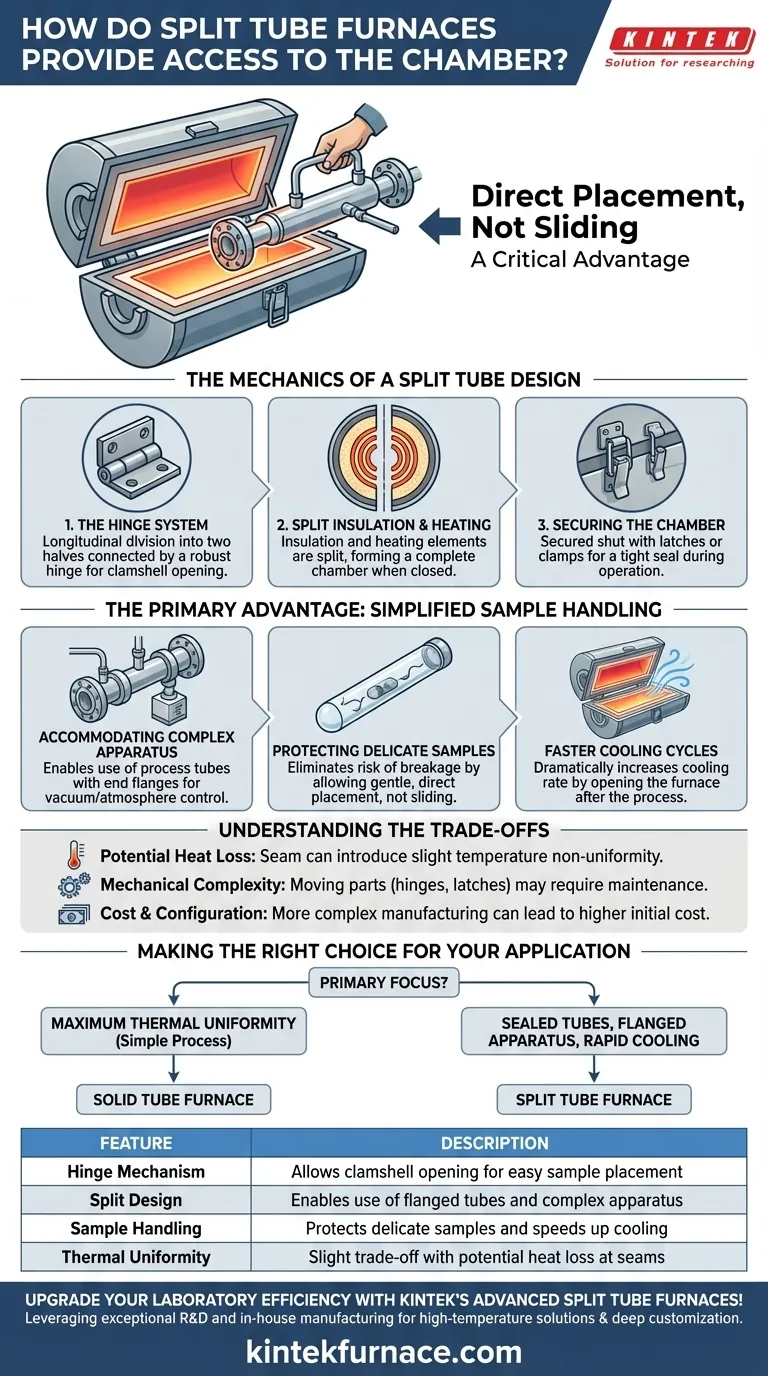

The Mechanics of a Split Tube Design

A split tube furnace's design is an elegant solution to a common laboratory problem. Its functionality is based on a few key engineering principles.

The Hinge System

The furnace is divided longitudinally into two semi-cylindrical halves. These halves are connected along one side by a robust hinge, allowing the top half to pivot away from the bottom.

This design enables operators to place a process tube directly onto the lower, stationary half of the furnace.

Split Insulation and Heating Elements

To function, both the insulation and the heating elements are also split between the two halves. When the furnace is closed, these components meet to form a complete, cylindrical heating chamber that surrounds the process tube.

High-quality furnaces are designed so that the seam between the halves has minimal impact on thermal uniformity.

Securing the Chamber

Once the top half is lowered, the furnace is secured shut using latches, clamps, or straps. This ensures a tight seal, minimizes heat loss, and maintains the structural integrity of the chamber during high-temperature operation.

The Primary Advantage: Simplified Sample Handling

The reason for choosing a split tube design almost always comes down to the nature of the sample and the process tube being used. It offers flexibility that a solid tube furnace cannot match.

Accommodating Complex Apparatus

The single greatest benefit is the ability to use process tubes with end flanges. These flanges are used for creating a vacuum or controlling the atmosphere inside the tube and are wider than the tube itself, making it impossible to slide them into a solid furnace.

With a split tube furnace, the entire flanged tube assembly can be set in place before closing the furnace around it.

Protecting Delicate Samples

Loading a long, fragile work tube (often made of quartz) into a solid furnace can be difficult and risks breakage. The sliding motion can also jar or disturb delicate samples already inside the tube.

A split tube furnace eliminates this risk by allowing for gentle, direct placement.

Faster Cooling Cycles

When a process is complete, the furnace can be opened. This dramatically increases the cooling rate of the sample and the work tube, significantly reducing the time between experimental runs.

Understanding the Trade-offs

While highly advantageous, the split tube design is not without its considerations. Understanding these trade-offs is key to making an informed decision.

Potential for Heat Loss

The seam where the two halves meet is a potential point of heat loss and can introduce a slight non-uniformity in the temperature profile compared to a perfectly monolithic solid tube furnace.

Modern designs minimize this effect, but it remains a fundamental characteristic of the split design.

Mechanical Complexity

Hinges and latches are moving parts. Over time, they can be subject to wear or misalignment, potentially requiring maintenance to ensure a proper seal.

Cost and Configuration

The manufacturing process for a split tube furnace is more complex, which can translate to a higher initial cost compared to a solid tube furnace with the same temperature range and chamber dimensions.

Making the Right Choice for Your Application

Selecting the correct furnace type depends entirely on your specific experimental or process requirements.

- If your primary focus is maximum thermal uniformity for a simple process: A solid tube furnace may provide a slight edge in temperature consistency and a lower initial cost.

- If your primary focus is working with sealed process tubes, vacuum systems, or flanged apparatus: The split tube design is not just a convenience; it is a necessity.

- If your primary focus is high throughput and rapid cooling: The ability to open the furnace to cool the sample makes the split tube the superior choice for quick cycle times.

Ultimately, the hinged design transforms the tube furnace from a simple heating device into a versatile platform for complex material processing.

Summary Table:

| Feature | Description |

|---|---|

| Hinge Mechanism | Allows clamshell opening for easy sample placement |

| Split Design | Enables use of flanged tubes and complex apparatus |

| Sample Handling | Protects delicate samples and speeds up cooling |

| Thermal Uniformity | Slight trade-off with potential heat loss at seams |

Upgrade your laboratory efficiency with KINTEK's advanced split tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs. Contact us today to discuss how our furnaces can enhance your sample handling and processing workflows!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity