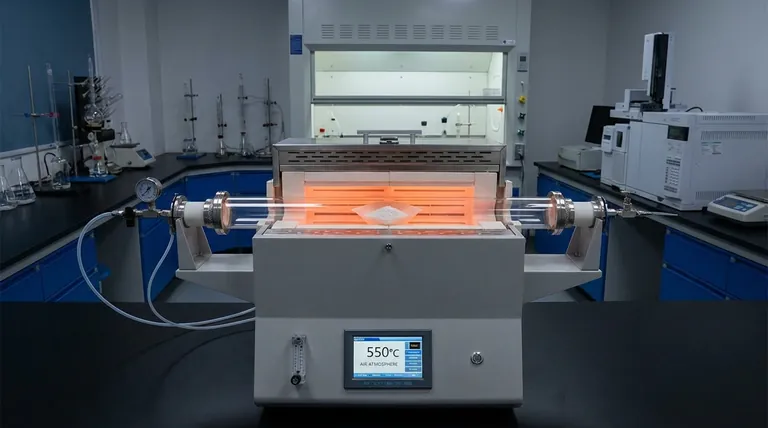

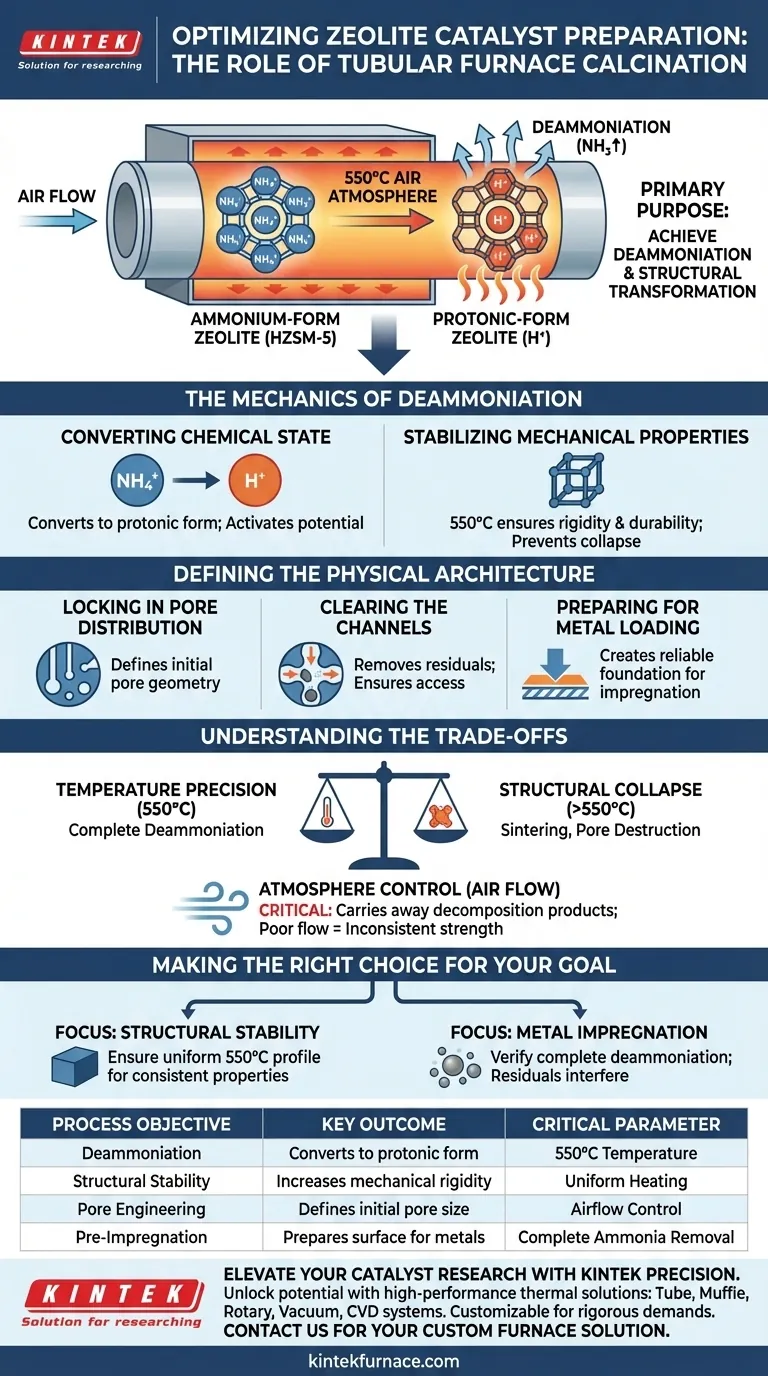

The primary purpose of utilizing a tubular furnace for the initial calcination of ammonium-form zeolites is to achieve deammoniation. By subjecting the material, such as HZSM-5, to 550°C in an air atmosphere, the furnace facilitates the thermal decomposition of ammonium ions. This critical step stabilizes the zeolite's mechanical properties and rigidly defines the initial pore distribution size.

Core Takeaway Initial calcination is not merely a drying step; it is a structural transformation. It converts the zeolite from a precursor state into a mechanically stable support with defined pore architecture, establishing the essential foundation required for subsequent metal impregnation.

The Mechanics of Deammoniation

Converting the Chemical State

The tubular furnace provides the thermal energy required to drive the deammoniation reaction. This process converts the ammonium-form zeolite into its protonic (hydrogen) form. This chemical shift is the prerequisite for activating the material's potential as a catalyst support.

Stabilizing Mechanical Properties

According to the primary technical data, a key outcome of this heat treatment is mechanical stabilization. The 550°C environment ensures the zeolite framework becomes rigid and durable. Without this stabilization, the material would likely lack the physical integrity to withstand downstream processing steps.

Defining the Physical Architecture

Locking in Pore Distribution

The thermal environment of the tubular furnace does more than alter surface chemistry; it defines the physical geometry of the catalyst. This specific calcination step determines the initial pore distribution size.

Clearing the Channels

While the primary goal is deammoniation, this high-temperature treatment also serves to clear micro-pores. As noted in supplementary data regarding similar zeolite synthesis, thermal treatment helps remove residual organic agents or blockages. This ensures the pore channels are open and accessible.

Preparing for Metal Loading

The ultimate goal of this initial calcination is preparation. By fixing the pore size and stabilizing the structure, the furnace creates a reliable foundation. This structural certainty is required for the successful impregnation of active metals in later stages of catalyst production.

Understanding the Trade-offs

Temperature Precision vs. Structural Collapse

Operating at the prescribed 550°C is a calculated balance. The temperature must be high enough to ensure complete deammoniation and the removal of impurities. However, excessive heat beyond this target can lead to the collapse of the zeolite framework or sintering, which would permanently destroy the pore structure and reduce surface area.

Atmosphere Control

The process relies on an air atmosphere within the tubular furnace. The flow and composition of this atmosphere are critical for carrying away decomposition products (such as ammonia gas). Poor airflow can lead to incomplete calcination, resulting in a catalyst with inconsistent mechanical strength and blocked pores.

Making the Right Choice for Your Goal

To maximize the effectiveness of your catalyst preparation, focus on the specific outcome you need from the tubular furnace:

- If your primary focus is Structural Stability: Ensure the furnace maintains a uniform 550°C profile to prevent thermal shock and guarantee consistent mechanical properties across the batch.

- If your primary focus is Metal Impregnation: Verify complete deammoniation has occurred, as residual ammonium ions will interfere with the uptake and distribution of metal precursors in the next step.

The tubular furnace transforms your zeolite from a raw chemical compound into a precisely engineered architectural support ready for activation.

Summary Table:

| Process Objective | Key Outcome | Critical Parameter |

|---|---|---|

| Deammoniation | Converts ammonium-form to protonic form | 550°C Temperature |

| Structural Stability | Increases mechanical rigidity and durability | Uniform Heating |

| Pore Engineering | Defines initial pore distribution and size | Airflow Control |

| Pre-Impregnation | Prepares surface for active metal loading | Complete Ammonia Removal |

Elevate Your Catalyst Research with KINTEK Precision

Unlock the full potential of your zeolite synthesis with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, we provide high-precision Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for the rigorous demands of catalyst calcination.

Whether you need to stabilize mechanical properties or ensure uniform deammoniation, our customizable lab furnaces provide the temperature accuracy and atmospheric control essential for your unique research needs. Contact us today to find your custom furnace solution.

Visual Guide

References

- Marco F. Paucar-Sánchez, M.A. Martín‐Lara. Impact of Metal Impregnation of Commercial Zeolites in the Catalytic Pyrolysis of Real Mixture of Post-Consumer Plastic Waste. DOI: 10.3390/catal14030168

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the importance of segmented temperature control in a tube furnace for Cu/Zn-SAN? Master Atomic Dispersion

- What heat treatment processes can be performed using tubular furnaces? Unlock Precision for Materials Science

- What are the benefits of a vertical tube furnace? Maximize Space and Purity in Your Lab

- What role does a laboratory tube furnace play in the carbonization process of porous carbon particles? Expert Insights

- What is the primary function of high-vacuum quartz tube sealing in Mo2S3 synthesis? Ensure Phase Purity and Precision

- What critical conditions does a tube furnace provide for ZIF-67 pyrolysis? Master Metal/Carbon Nanocomposite Production

- How is the high-temperature environment of a tube furnace used for adsorbent regeneration? Achieve Precise Recovery

- What is the importance of maintaining an argon atmosphere in a quartz tube furnace for LiFePO4? Achieve Pure Synthesis