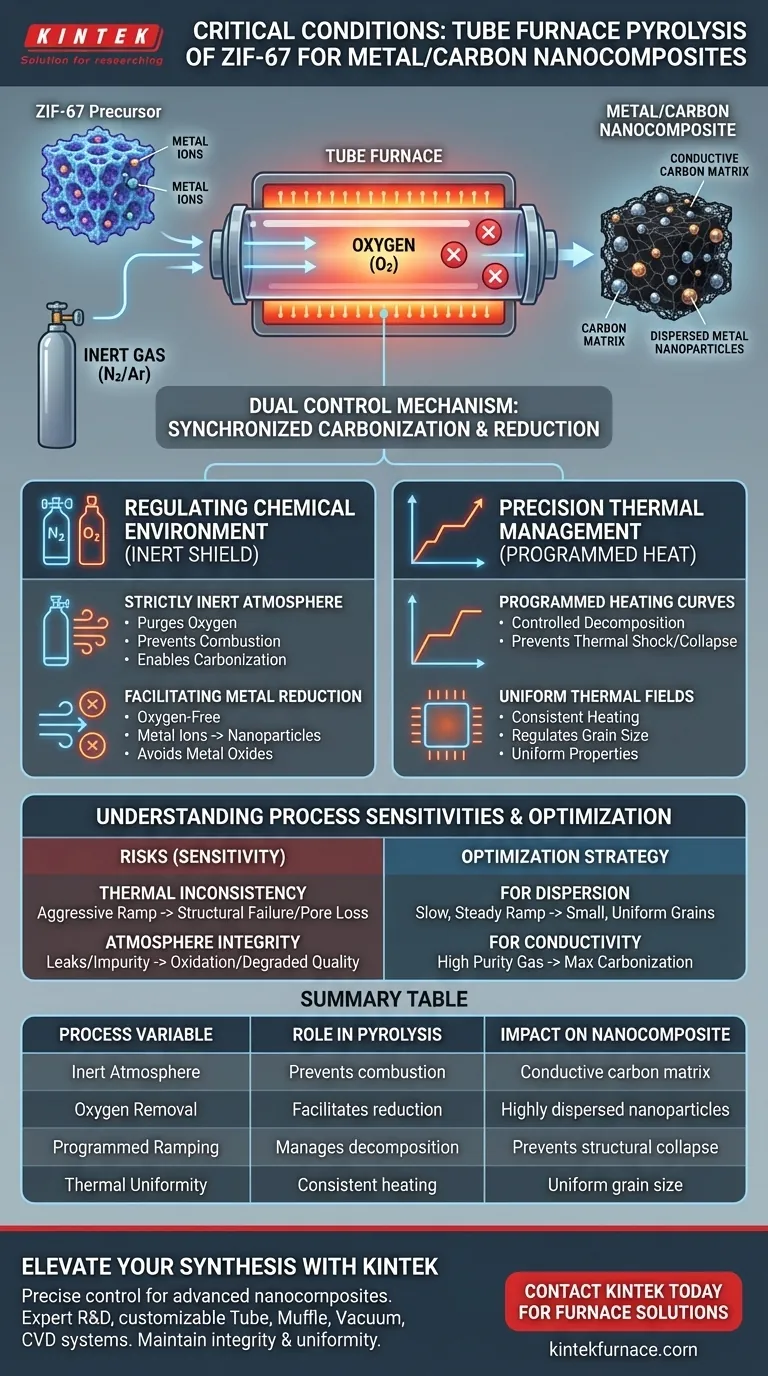

A tube furnace establishes a strictly inert, oxygen-free environment coupled with precise thermal regulation, which is the absolute prerequisite for converting ZIF-67 into functional metal/carbon nanocomposites. By utilizing protective gases like nitrogen or argon and executing programmable heating curves, the furnace allows organic ligands to carbonize rather than combust, while simultaneously reducing metal ions into highly dispersed nanoparticles.

The core value of the tube furnace lies in its ability to synchronize the carbonization of the framework with the reduction of metal species. Without this dual control mechanism, the material would simply oxidize or suffer from uncontrolled particle agglomeration, destroying the desired nanostructure.

Regulating the Chemical Environment

The Necessity of an Inert Shield

The primary function of the tube furnace in this process is to provide a strictly inert protective atmosphere.

By continuously flowing gases such as nitrogen or argon, the system purges oxygen from the chamber. This ensures that the organic ligands within the ZIF-67 structure undergo carbonization—transforming into a conductive carbon matrix—rather than burning away as they would in air.

Facilitating Metal Reduction

The oxygen-free environment is equally critical for the metal components of ZIF-67.

Under these conditions, the metal ions embedded in the framework are reduced into metallic nanoparticles. If oxygen were present, these ions would likely form large metal oxides, losing the specific catalytic properties associated with dispersed metallic species.

Precision Thermal Management

Programmed Heating Curves

Success depends not just on reaching a high temperature, but on the specific path taken to get there.

The tube furnace utilizes precise programmed heating curves (ramps). This controlled elevation of temperature ensures that the decomposition of the ZIF-67 backbone occurs gradually, preventing structural collapse that might occur under thermal shock.

Uniform Thermal Fields

Within the heating zone, the tube furnace maintains a uniform thermal field.

This uniformity is vital for the controlled regulation of the material's final properties. It ensures that the degree of carbonization is consistent throughout the sample and strictly dictates the grain size of the resulting metal particles, preventing uneven growth.

Understanding Process Sensitivities

The Risk of Thermal Inconsistency

While tube furnaces offer precision, improper programming can lead to structural failure.

If the heating ramp is too aggressive, the rapid release of volatiles can destroy the porous architecture of the carbon matrix. This often results in excessive shrinkage or a loss of the high dimensional accuracy required for advanced applications.

Atmosphere Integrity

The "inert" status of the environment is fragile and binary; it is either oxygen-free or it is failing.

Even minor leaks or impure gas sources will introduce oxygen during the high-temperature phase. This immediately halts the reduction process and degrades the carbon quality, rendering the final composite effectively useless for its intended application.

Optimizing Your Pyrolysis Strategy

To achieve the best results with ZIF-67 precursors, align your furnace settings with your specific material goals:

- If your primary focus is particle dispersion: Prioritize a slow, steady heating ramp to prevent metal migration and ensure small, uniform grain sizes.

- If your primary focus is carbon conductivity: Ensure the highest possible purity of nitrogen or argon flow to maximize the degree of carbonization without oxidation.

The precise coordination of inert gas flow and thermal programming is the defining factor in successfully engineering high-performance metal/carbon nanocomposites.

Summary Table:

| Process Variable | Role in ZIF-67 Pyrolysis | Impact on Final Nanocomposite |

|---|---|---|

| Inert Atmosphere | Prevents combustion of organic ligands | Enables formation of a conductive carbon matrix |

| Oxygen Removal | Facilitates chemical reduction of metal ions | Ensures highly dispersed metallic nanoparticles |

| Programmed Ramping | Manages decomposition of ZIF-67 backbone | Prevents structural collapse and pore loss |

| Thermal Uniformity | Maintains consistent heating across sample | Dictates uniform grain size and material properties |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise control over pyrolysis is the difference between advanced nanocomposites and failed experiments. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Vacuum, and CVD systems designed to maintain the strict atmospheric integrity and thermal uniformity required for ZIF-67 conversion. Our furnaces are fully customizable to meet your unique laboratory needs, ensuring high dimensional accuracy and superior carbon conductivity every time.

Ready to optimize your high-temperature research? Contact our technical experts today to find the perfect furnace solution for your application.

Visual Guide

References

- D. G. Muratov, А. В. Зорин. Metal-organic frameworks and composites on their basis: structure, synthesis methods, electrochemical properties and application prospects (a review). DOI: 10.3897/j.moem.10.2.126396

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the different types of tube furnaces and their features? Choose the Right Furnace for Your Lab

- How does annealing in a tube vacuum furnace optimize WS2 thin films? Master Structural Integrity & Efficiency

- What role does a high-vacuum tube furnace play in helium bubble studies? Master Thermal Activation & Material Purity

- What environmental conditions does a high-temperature tube furnace simulate for corrosion? Replicate Boiler Realities

- How vacuum pumping affects Zr2.5Nb nitriding? Achieve pure ZrN surfaces in high-temp tube furnaces.

- How does the temperature controller function in a 70mm tube furnace? Achieve Precise Thermal Control for Your Lab

- What is the academic use of drop tube furnaces? Unlock Precise High-Temp Research for Materials and Energy

- How does a tube furnace facilitate the structural stabilization of lignin? Mastering Lignin-to-Carbon Transformation