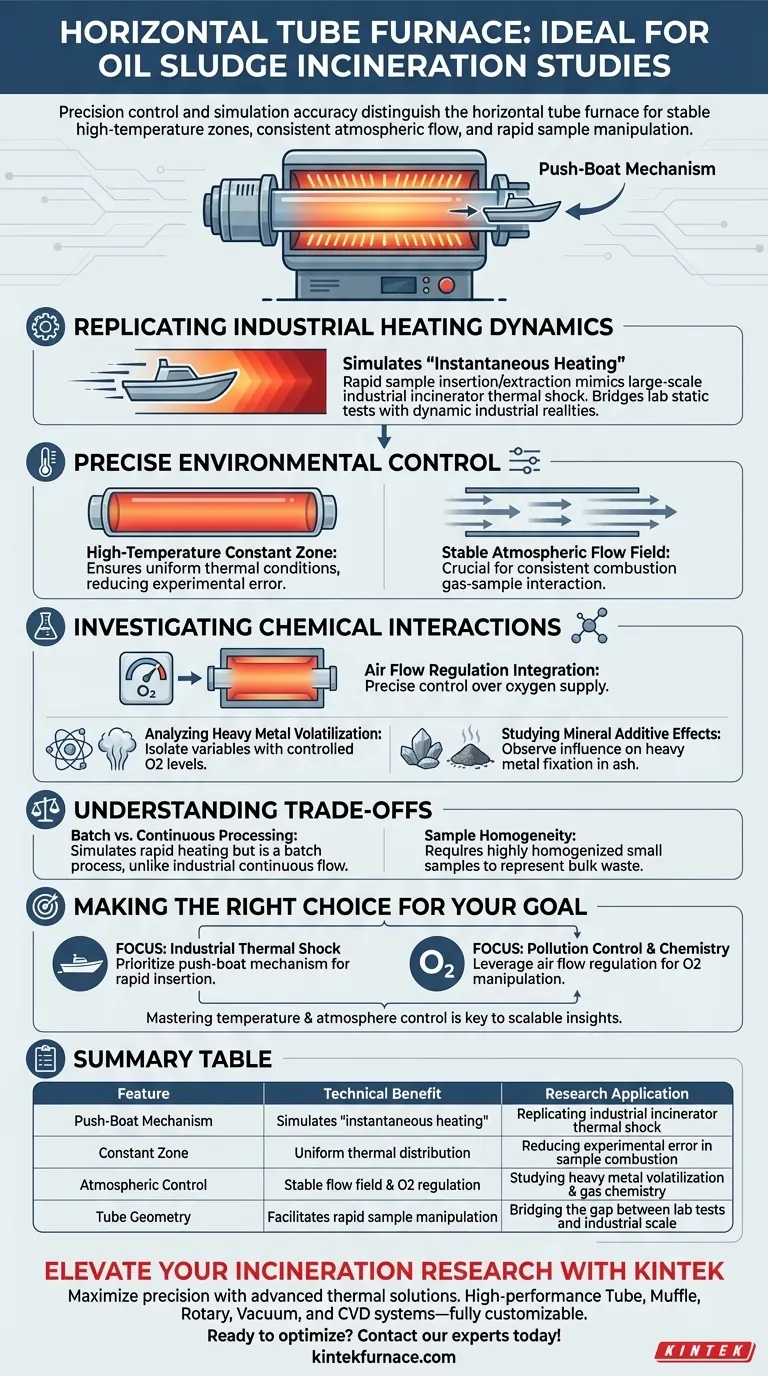

Precision control and simulation accuracy distinguish the horizontal tube furnace. Ideally suited for oil sludge incineration studies, this device offers a stable high-temperature constant zone and a consistent atmospheric flow field. Its design specifically supports rapid sample manipulation to mimic industrial heating conditions, while allowing for the exact regulation of oxygen required to analyze complex chemical interactions.

The core value of the horizontal tube furnace lies in its ability to replicate industrial "instantaneous heating" through manual mechanisms while maintaining a strictly controlled environment for analyzing heavy metal behavior.

Replicating Industrial Heating Dynamics

The Push-Boat Mechanism

The furnace utilizes an elongated quartz or ceramic tube design. This specific geometry facilitates the use of "push-boat" mechanisms.

Simulating Instantaneous Heating

Researchers can rapidly insert and extract samples using this mechanism. This rapid movement accurately simulates the instantaneous heating processes found in large-scale industrial incinerators.

Bridging Lab and Industry

By mimicking these rapid thermal changes, the device bridges the gap between static laboratory tests and dynamic industrial realities.

Precise Environmental Control

High-Temperature Constant Zone

The furnace provides a reliable, high-temperature constant zone. This ensures that the thermal conditions remain uniform across the sample, reducing experimental error.

Stable Atmospheric Flow Field

Beyond temperature, the device maintains a stable atmospheric flow field. This stability is crucial for ensuring that combustion gases interact consistently with the sample.

Investigating Chemical Interactions

Air Flow Regulation Integration

The horizontal tube furnace allows for the integration of sophisticated air flow regulation systems. This feature grants researchers precise control over the oxygen supply entering the reaction zone.

Analyzing Heavy Metal Volatilization

With controlled oxygen levels, researchers can isolate variables to study specific chemical behaviors. This is particularly useful for observing how heavy metals volatilize during incineration.

Studying Mineral Additive Effects

The controlled environment is also essential for testing mineral additives. It allows for detailed observation of how these additives influence the fixation of heavy metals within the ash.

Understanding the Trade-offs

Batch vs. Continuous Processing

While the push-boat mechanism simulates rapid heating, it remains a batch process. This differs from the continuous flow of material seen in many full-scale industrial operations.

Sample Homogeneity

The scale of a laboratory tube furnace requires relatively small sample sizes. Researchers must ensure their oil sludge samples are highly homogenized to accurately represent bulk industrial waste.

Making the Right Choice for Your Goal

To maximize the utility of a horizontal tube furnace in your research, align the device's specific features with your primary experimental objectives.

- If your primary focus is simulating industrial thermal shock: Prioritize the push-boat mechanism to replicate rapid insertion and instantaneous heating rates.

- If your primary focus is pollution control and chemistry: Leverage the air flow regulation system to manipulate oxygen levels and study additive effects on heavy metal fixation.

Mastering the precise control of both temperature and atmosphere is the key to deriving scalable insights from laboratory incineration studies.

Summary Table:

| Feature | Technical Benefit | Research Application |

|---|---|---|

| Push-Boat Mechanism | Simulates "instantaneous heating" | Replicating industrial incinerator thermal shock |

| Constant Zone | Uniform thermal distribution | Reducing experimental error in sample combustion |

| Atmospheric Control | Stable flow field & O2 regulation | Studying heavy metal volatilization & gas chemistry |

| Tube Geometry | Facilitates rapid sample manipulation | Bridging the gap between lab tests and industrial scale |

Elevate Your Incineration Research with KINTEK

Maximize the precision of your oil sludge and heavy metal studies with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research parameters. Whether you need to simulate rapid industrial heating or achieve precise atmospheric regulation, KINTEK offers the reliability your lab demands.

Ready to optimize your thermal processes? Contact our technical experts today to discuss your custom furnace requirements!

Visual Guide

References

- Yue Han, Ming-xin Xu. Study on the Effect of Mineral Compounds on the Behavior of Heavy Metals During Oily Sludge Incineration. DOI: 10.3390/en18040834

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why are vacuum tube furnaces considered valuable in various fields? Unlock Precision in Material Processing

- How does a tube furnace facilitate the activation and shaping of NiCoO2 nanowires? Optimize Your Catalyst Performance

- What are the advantages of using high-temperature tube or vacuum furnaces for LLZO sintering? Achieve Optimal Density

- What is the purpose of introducing high-purity nitrogen into a tube furnace? Enhance Biomass Torrefaction Efficiency

- What role does a high-temperature Tube Furnace play in ScSZ thin film post-treatment? Master Structural Refinement

- What is the role of a tube furnace during fuel cell feasibility studies? Optimize Your Thermal Control

- What conditions does a tubular reactor provide for catalyst reduction? Master Platinum, Copper, and Nickel Activation

- What is the maximum sample size that the 3-Zone tube furnace can accommodate? Optimize for Uniform Heating and CVD