High-temperature tube and vacuum furnaces provide the precise environmental control required to successfully sinter Li7La3Zr2O12 (LLZO). These systems allow the process to occur under specific, regulated atmospheres—such as dry air or argon—which effectively suppresses lithium volatilization and neutralizes the detrimental effects of environmental moisture while supporting temperatures above 1100°C.

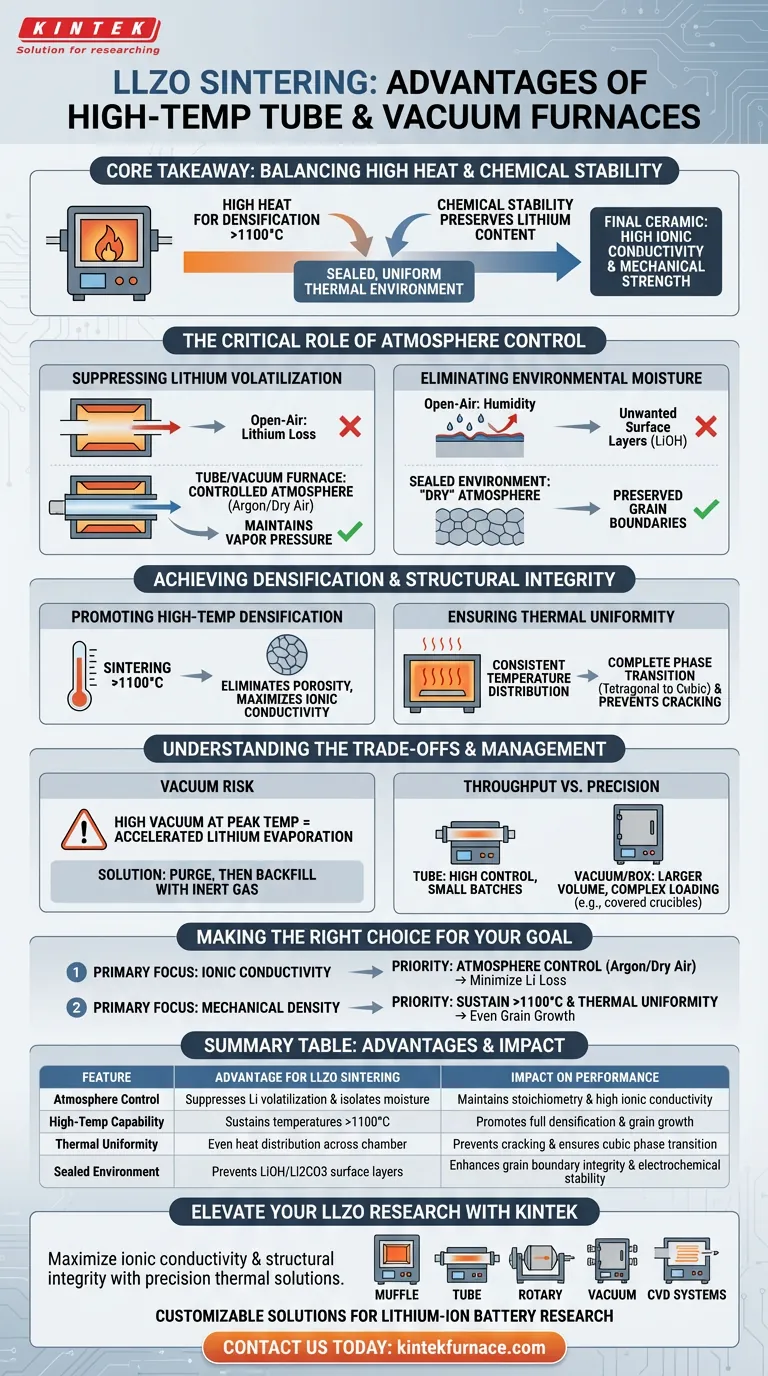

Core Takeaway Processing LLZO requires a delicate balance between high heat for densification and chemical stability to preserve lithium content. Advanced furnaces solve this by creating a sealed, uniform thermal environment that prevents material degradation, ensuring the final ceramic achieves high ionic conductivity and mechanical strength.

The Critical Role of Atmosphere Control

The primary challenge in sintering LLZO is its chemical instability at high temperatures. Standard open-air firing often leads to lithium loss and moisture contamination, which degrades performance.

Suppressing Lithium Volatilization

Lithium is highly volatile at the sintering temperatures required for LLZO (typically above 1100°C). Tube and vacuum furnaces allow for the introduction of specific atmospheres, such as Argon or dry air, or the use of sacrificial powder beds within a controlled chamber. This controlled environment maintains the necessary vapor pressure to prevent lithium from evaporating out of the crystal structure.

Eliminating Environmental Moisture

LLZO is sensitive to humidity, which can lead to the formation of unwanted surface layers (like Lithium Hydroxide) that impede ionic conductivity. These furnaces provide a sealed environment that isolates the material from ambient humidity. By processing in a "dry" atmosphere, the integrity of the grain boundaries is preserved, resulting in superior electrochemical performance.

Achieving Densification and Structural Integrity

Beyond chemistry, the physical properties of the ceramic rely heavily on the thermal precision these furnaces provide.

Promoting High-Temperature Densification

To achieve a dense ceramic pellet with high mechanical strength, LLZO typically requires sintering temperatures exceeding 1100°C. High-temperature tube and vacuum furnaces are designed to reach and sustain these extreme temperatures reliably. This heat promotes grain growth and eliminates porosity, which is essential for maximizing the material's ionic conductivity.

Ensuring Thermal Uniformity

Consistency across the sample is vital to prevent cracking and ensure a complete phase transition from tetragonal to cubic structures. These furnaces offer excellent thermal uniformity, ensuring that the entire sample experiences the same thermal history. This prevents local temperature differences that could lead to incomplete phase transitions, side products, or thermal stress cracks.

Understanding the Trade-offs

While these furnaces offer significant advantages, they introduce specific complexities that must be managed.

The Risk of Vacuum on Stoichiometry

While "vacuum furnaces" are advantageous for their sealing and purging capabilities, sintering LLZO under a high vacuum at peak temperatures can be detrimental. The low pressure can accelerate lithium evaporation rather than prevent it. Therefore, these furnaces are best used to purge oxygen and moisture, after which they should often be backfilled with an inert gas rather than holding a hard vacuum during the soak.

Throughput vs. Precision

Tube furnaces offer the highest degree of atmosphere control for small batches but are often limited in sample volume. In contrast, larger vacuum or box furnaces can process more material but may require more complex loading configurations (such as covered crucibles) to maintain the local lithium atmosphere around the samples.

Making the Right Choice for Your Goal

To maximize the performance of your LLZO electrolyte, align your furnace operation with your specific material objectives.

- If your primary focus is Ionic Conductivity: Prioritize atmosphere control (Argon or Dry Air) to minimize lithium loss and ensure the cubic phase is maintained.

- If your primary focus is Mechanical Density: Ensure the furnace can sustain temperatures >1100°C with high thermal uniformity to promote even grain growth without cracking.

The success of LLZO sintering lies not just in reaching high temperatures, but in the ability to strictly control the chemical environment during the thermal cycle.

Summary Table:

| Feature | Advantage for LLZO Sintering | Impact on Performance |

|---|---|---|

| Atmosphere Control | Suppresses lithium volatilization and isolates moisture | Maintains stoichiometry and high ionic conductivity |

| High-Temp Capability | Sustains temperatures >1100°C | Promotes full densification and grain growth |

| Thermal Uniformity | Even heat distribution across the chamber | Prevents cracking and ensures cubic phase transition |

| Sealed Environment | Prevents formation of LiOH/Li2CO3 surface layers | Enhances grain boundary integrity and electrochemical stability |

Elevate Your LLZO Research with KINTEK

Maximize the ionic conductivity and structural integrity of your solid-state electrolytes with KINTEK’s precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of lithium-ion battery research.

Ready to optimize your sintering process? Contact us today to discuss how our high-temperature furnaces can deliver the atmosphere control and thermal precision your lab needs.

Visual Guide

References

- Degradation mechanisms in low-voltage Wadsley–Roth TiNb<sub>2</sub>O<sub>7</sub> electrodes upon cycling with Li. DOI: 10.1039/d4ta06441k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a stable argon atmosphere necessary when using a tube furnace for GH4099 alloy? Ensure Material Integrity

- How does a multi-tube pyrolysis furnace achieve precise temperature control? Advanced Hardware & PID Logic Explained

- What role does a high-temperature tube furnace play in the post-treatment of Ir-TiO2 samples? Master Material Purity

- Why is a tube high-temperature furnace required for Au@MoSe2/graphene composites? Precision Reaction Control

- What is the role of a high-temperature tube furnace in the preparation of TiO2-alpha-Ga2O3 heterostructures?

- What are the types of vacuum tube furnaces based on? Key Classifications for Your Lab

- What is the importance of using a quartz tube for water quenching? Ensure Alloy Integrity with Thermal Shock Resistance

- What are some examples of applications for three-zone tube furnaces in advanced materials processing? Unlock Precision Thermal Control for Your Lab