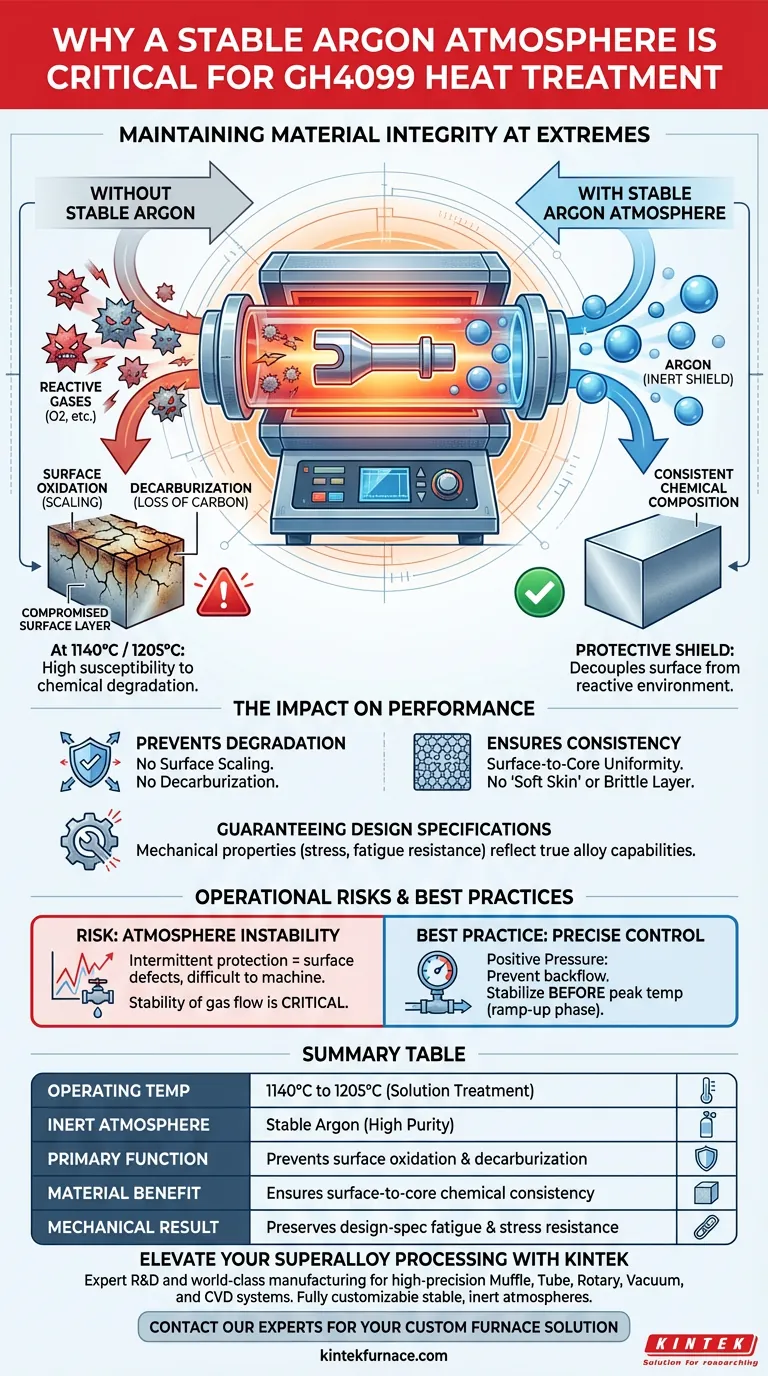

Maintaining a stable argon atmosphere is the single most critical factor in preventing the chemical degradation of GH4099 alloy during heat treatment. Without this inert barrier, the high temperatures required for solution treatment—specifically 1140°C or 1205°C—would cause immediate surface oxidation and decarburization.

The argon atmosphere acts as a protective shield that decouples the alloy’s surface from the reactive environment. This ensures that the chemical composition remains consistent from the surface to the core, which is the only way to guarantee the material achieves its engineered mechanical properties.

Preserving Material Integrity at Extremes

Preventing Chemical Degradation

When processing GH4099, you are often operating at solution treatment temperatures of 1140°C or 1205°C, followed by aging processes.

At these thermal extremes, the alloy is highly susceptible to reacting with oxygen and other atmospheric gases.

A stable argon environment effectively displaces these reactive gases. This prevents surface oxidation (scaling) and decarburization (loss of carbon content), both of which compromise the material's structural integrity.

Ensuring Surface-to-Core Consistency

The goal of high-precision heat treatment is uniformity.

If the atmosphere is compromised, the surface chemistry of the alloy changes while the core remains stable.

Argon protection ensures that the chemical composition consistency is maintained throughout the entire cross-section of the part. This prevents the formation of a "soft skin" or brittle surface layer that behaves differently than the core.

The Impact on Mechanical Performance

Guaranteeing Design Specifications

The mechanical properties of GH4099 are tightly coupled to its specific chemical makeup.

Any loss of elements at the surface alters how the material responds to stress, fatigue, and heat.

By using a tube furnace with a controlled atmosphere, you ensure that the physical properties tested after treatment reflect the true capabilities of the alloy, rather than a compromised surface layer.

Understanding the Operational Risks

The Consequence of Atmosphere Instability

While a tube furnace offers high thermal precision, thermal control alone is insufficient without atmosphere control.

If the argon flow is unstable or impure, protection becomes intermittent.

Even brief exposure to oxygen at temperatures above 1100°C can initiate surface defects that are difficult to machine away later. Therefore, the stability of the gas flow is just as critical as the stability of the temperature.

Making the Right Choice for Your Process

To achieve optimal results with GH4099, you must align your furnace settings with your specific quality goals.

- If your primary focus is Surface Integrity: Ensure your argon flow rate is calculated to provide positive pressure, preventing any backflow of outside air into the tube.

- If your primary focus is Mechanical Consistency: Verify that the atmosphere is stabilized before the furnace reaches peak temperatures (1140°C/1205°C) to protect the alloy during the ramp-up phase.

Precise atmosphere control is not an optional feature; it is the baseline requirement for validating the performance of high-temperature superalloys.

Summary Table:

| Feature | Impact on GH4099 Alloy Treatment |

|---|---|

| Operating Temp | 1140°C to 1205°C (Solution Treatment) |

| Inert Atmosphere | Stable Argon (High Purity) |

| Primary Function | Prevents surface oxidation and decarburization |

| Material Benefit | Ensures surface-to-core chemical consistency |

| Mechanical Result | Preserves design-spec fatigue and stress resistance |

Elevate Your Superalloy Processing with KINTEK

Don't let atmospheric contamination compromise your GH4099 components. Backed by expert R&D and world-class manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding lab environments. Our furnace solutions are fully customizable to provide the stable, inert atmospheres essential for high-temperature superalloy integrity.

Ready to achieve superior heat treatment results? Contact our experts today to find your custom furnace solution.

Visual Guide

References

- Jiahao Liu, Qiang Hu. Influence of Various Heat Treatments on Microstructures and Mechanical Properties of GH4099 Superalloy Produced by Laser Powder Bed Fusion. DOI: 10.3390/ma17051084

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What specific process environment does a tube furnace provide for PtTe2 tellurization? Achieve High Crystallinity

- What are the space-saving benefits of a tube furnace? Maximize Lab Efficiency with Compact Design

- What is a horizontal electric furnace designed for? Achieve Precise Thermal Processing in Controlled Environments

- What are the roles of a vacuum tube furnace and a CCD camera in high-temperature wettability testing? Key Insights

- What is the function of a high-temperature tube furnace? Master Grain Growth for Microcrystalline Alloy Samples

- How does a dual-zone tube furnace facilitate monolayer synthesis? Precision Growth for MoS2 & WS2

- What are the advantages of combining an online mass spectrometer with a fixed-bed reactor? Boost Kinetic Precision

- What are the main applications of a drop tube furnace? Unlock Insights in Energy and Materials Research