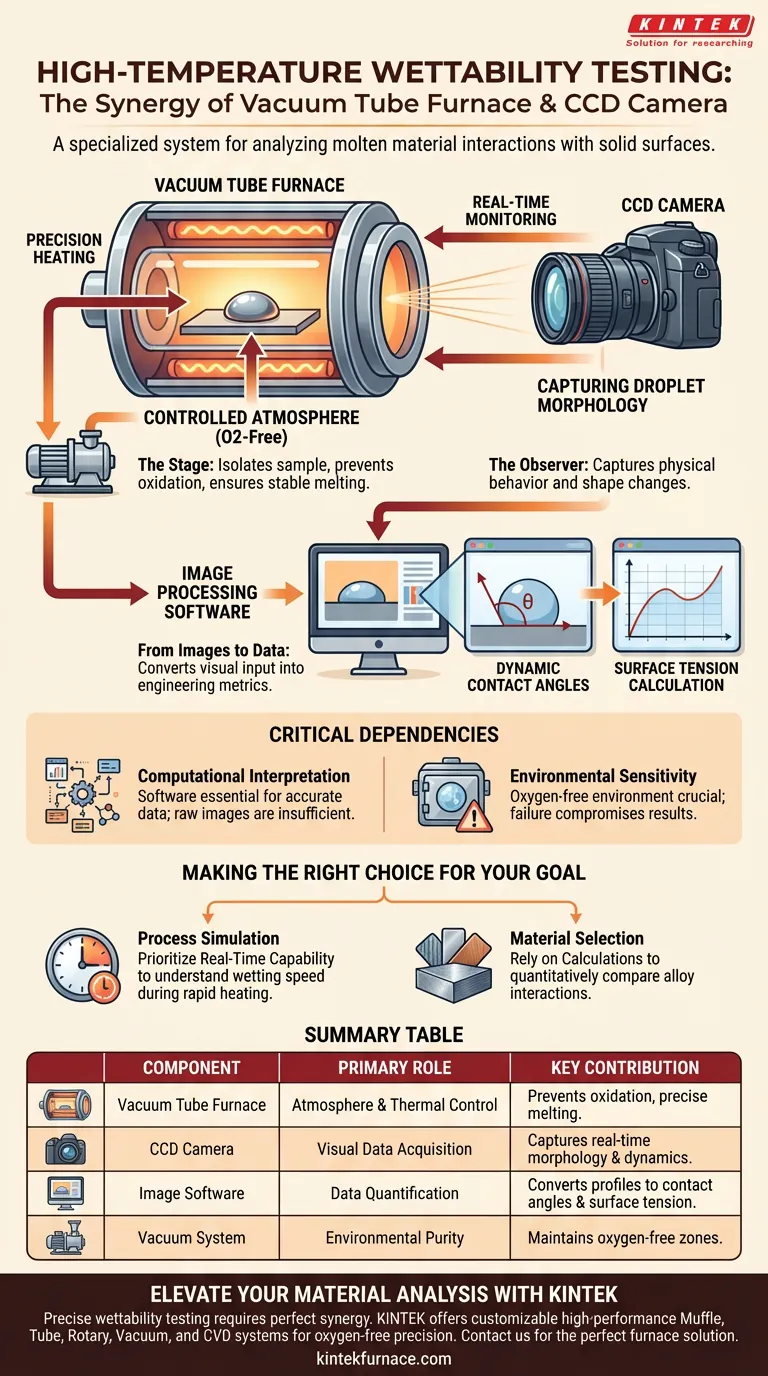

The combination of a vacuum tube furnace and a CCD camera creates a specialized system for analyzing how molten materials interact with solid surfaces. The vacuum tube furnace provides the essential heating and atmospheric control to melt metal droplets without oxidation, while the CCD camera acts as the sensing instrument, capturing the changing shape of the droplet in real-time for analysis.

By integrating precise thermal control with optical monitoring, this setup converts visual data into quantitative metrics, allowing for the accurate calculation of dynamic contact angles, surface tension, and overall wettability.

The Role of the Vacuum Tube Furnace

The furnace serves as the stage for the experiment, creating the specific conditions necessary to simulate high-temperature processing or service environments.

Creating a Controlled Atmosphere

The primary function of the vacuum tube furnace is to isolate the sample. It provides a controlled, oxygen-free environment. This is critical because oxygen causes rapid oxidation at high temperatures, which would alter the surface properties and ruin the validity of a wettability test.

Precision Heating

Beyond merely isolating the sample, the furnace delivers precise heating. It must bring the metal to its melting point on a specific substrate in a stable manner, ensuring that the droplet forms naturally without thermal shock or uneven temperature gradients.

The Role of the CCD Camera

If the furnace is the stage, the CCD (Charge-Coupled Device) camera is the observer. Its role is to capture the physical behavior of the material as it transitions from solid to liquid.

Capturing Droplet Morphology

The camera is focused directly on the sample inside the furnace. It records the morphology (shape and structure) of the droplet. This visual record is the raw data required to determine how well the liquid spreads over the solid surface.

Real-Time Monitoring

Wetting is a dynamic process. The CCD camera captures these changes in real-time, documenting how the droplet expands or contracts immediately after melting. This allows researchers to see not just the final state, but the rate of wetting.

From Images to Data: The System at Work

The hardware described above relies on integration with image processing software to turn visual input into engineering data.

Measuring Dynamic Contact Angles

By analyzing the images captured by the camera, the software measures the dynamic contact angle. This is the angle at which the liquid interface meets the solid surface, serving as the primary indicator of wettability.

Calculating Surface Tension

The shape of the droplet is governed by the balance of forces acting upon it. The system uses the droplet's profile to calculate surface tension, a fundamental property that dictates how the liquid will behave during casting, brazing, or coating processes.

Understanding the Dependencies

While this system enables sophisticated analysis, it relies heavily on the integration between hardware and software.

The Necessity of Computational Interpretation

The raw images from the CCD camera are insufficient on their own. The system's value is entirely dependent on image processing software. Without accurate algorithms to interpret the droplet's edges and angles, the high-quality images cannot yield precise quantitative data.

Environmental Sensitivity

The accuracy of the measurement is inextricably linked to the furnace's ability to maintain an oxygen-free environment. Even a slight failure in the vacuum or atmosphere control will compromise the morphology of the droplet, leading to incorrect calculations of surface tension and wettability.

Making the Right Choice for Your Goal

To maximize the value of this testing setup, focus your analysis on the specific metric that aligns with your engineering objectives.

- If your primary focus is process simulation: Prioritize the real-time capability of the CCD camera to understand how quickly a material wets a surface during rapid heating cycles.

- If your primary focus is material selection: Rely on the surface tension and contact angle calculations to quantitatively compare how different alloys interact with a specific substrate.

Ultimately, the power of this system lies in its ability to visualize and quantify the invisible forces governing high-temperature material interfaces.

Summary Table:

| Component | Primary Role | Key Contribution to Testing |

|---|---|---|

| Vacuum Tube Furnace | Atmosphere & Thermal Control | Prevents oxidation and ensures precise, stable melting conditions. |

| CCD Camera | Visual Data Acquisition | Captures real-time droplet morphology and wetting dynamics. |

| Image Software | Data Quantification | Converts visual profiles into contact angles and surface tension metrics. |

| Vacuum System | Environmental Purity | Maintains oxygen-free zones to preserve material surface properties. |

Elevate Your Material Analysis with KINTEK

Precise wettability testing requires the perfect synergy between thermal stability and optical clarity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs.

Whether you are analyzing advanced alloys or developing new coatings, our high-temperature furnaces provide the oxygen-free precision your research demands. Contact us today to find the perfect furnace solution for your lab!

Visual Guide

References

- Yongliang Chen, Shiwei Jiang. Wettability and Mechanical Properties of Red Mud–Al2O3 Composites. DOI: 10.3390/ma17051095

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What technical conditions does a tube atmosphere furnace provide for Cu/TiO2/ZSM-5? Optimize Catalyst Reduction

- Why is a high-temperature tube furnace required for the preparation of barium ferrite? Achieve Optimal Magnetism

- How is a vertical alumina tube resistance furnace applied in the hydrogen reduction of bauxite residue particles?

- What critical experimental conditions does a tube furnace provide for carbonizing PI-COFs? Master Thermal Precision

- What are some common applications of tube furnaces in laboratories? Unlock Precision in Material Processing

- Why is precise atmosphere control in a tube furnace critical for Ga2O3 annealing? Optimize Thin Film Defect Engineering

- What environmental conditions does a vacuum tube furnace provide for FTO(p)/ZnS(p) films? High-Purity Post-Treatment

- What are the application areas of a 70mm tube furnace? Precision Heating for Materials Science and More