At its core, a 70mm tube furnace is a highly controlled environment for processing materials at extreme temperatures. It finds primary application in advanced scientific and engineering fields, including material science for thermal analysis, chemical engineering for catalyst synthesis, nanotechnology for creating novel materials, and electronics for semiconductor fabrication and thin-film deposition.

A 70mm tube furnace is more than a simple oven; it is a precision instrument for manipulating matter. Its value lies not just in its ability to reach high temperatures, but in its capacity to create and maintain a tightly controlled atmosphere—be it vacuum, inert gas, or a reactive chemical environment.

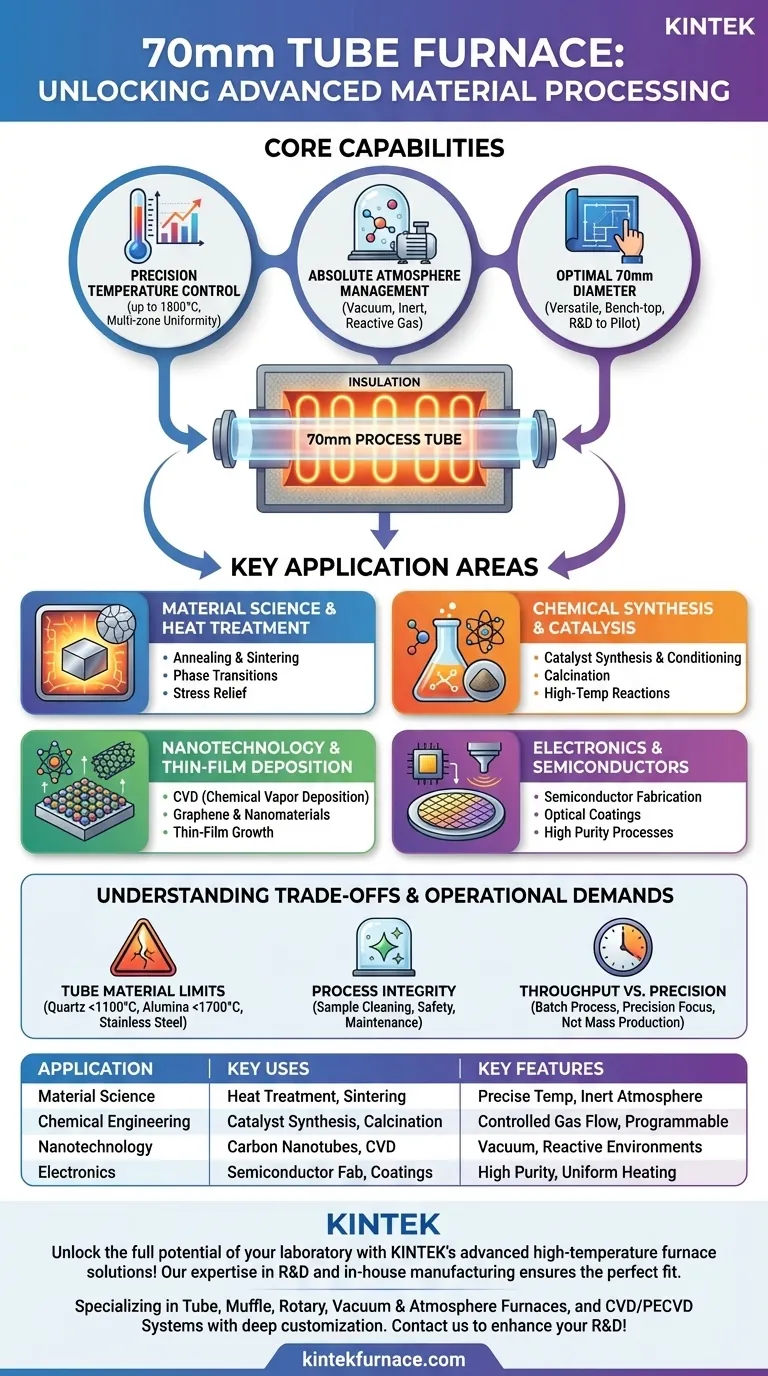

The Core Capabilities of a Tube Furnace

To understand its applications, you must first understand its fundamental capabilities. The furnace's utility is defined by its ability to precisely control the three critical variables of material processing: temperature, atmosphere, and pressure.

Precision Temperature Control

A tube furnace provides exceptional control over the thermal environment. Modern units offer fully programmable controllers that can execute complex heating, soaking, and cooling profiles with high accuracy.

Many are available in multi-zone configurations, where separate heaters along the tube's length create an extended, highly uniform temperature zone. This is critical for ensuring that an entire sample is processed under identical conditions, with operating temperatures often reaching up to 1800°C.

Absolute Atmosphere Management

The sealed tube design is the furnace's defining feature. By using specialized end caps and seals, operators can completely isolate the sample from the outside air.

This allows for processing under a deep vacuum (down to 10⁻⁵ torr), in a flow of inert gas (like argon or nitrogen) to prevent oxidation, or with a precise mixture of reactive gases. This capability is the foundation for advanced processes like chemical vapor deposition (CVD).

The Significance of the 70mm Diameter

The 70mm inner diameter represents a common and versatile size. It strikes a balance between accommodating sufficiently large samples or multiple smaller samples for reasonable throughput, while remaining compact enough for typical laboratory bench-top use.

This diameter is well-suited for research, process development, and small-scale pilot production before scaling up to larger, industrial systems.

Key Application Areas in Detail

The combination of precise temperature and atmosphere control enables a wide range of sophisticated applications across multiple disciplines.

Material Science & Heat Treatment

In material science, tube furnaces are workhorses for heat treatment processes. This includes annealing to relieve stresses in metals, sintering to fuse ceramic powders into a solid, and studying phase transitions at specific temperatures. The controlled, inert atmosphere prevents unwanted chemical reactions like oxidation.

Chemical Synthesis & Catalysis

Chemical engineers use tube furnaces for creating and conditioning catalysts. Processes like calcination—heating a material to drive off impurities and induce phase changes—rely on the furnace's precise temperature ramps and controlled gas flow. It is also used for various forms of high-temperature chemical synthesis.

Nanotechnology & Thin-Film Deposition

This is where the furnace's advanced capabilities truly shine. It is essential for synthesizing nanomaterials like carbon nanotubes or graphene via chemical vapor deposition (CVD).

In CVD, precursor gases are introduced into the hot tube, where they decompose and deposit a high-purity thin film onto a substrate. This process is fundamental to manufacturing semiconductors and advanced optical coatings.

Understanding the Trade-offs and Operational Demands

While powerful, a tube furnace is a technical instrument that requires knowledge to operate effectively and safely.

Tube Material Limitations

The process tube itself is a critical component, and the material choice dictates the furnace's limits.

- Quartz: Offers high purity and excellent vacuum performance but is typically limited to around 1100°C.

- Alumina (Ceramic): Can withstand very high temperatures (1700°C or more) but can be more susceptible to thermal shock if heated or cooled too quickly.

- Stainless Steel: Durable and robust, but has lower temperature limits and can potentially react with or contaminate certain sensitive materials.

The Importance of Process Integrity

Achieving accurate, repeatable results demands discipline. Samples must be properly cleaned and dried before processing to avoid outgassing and contamination. Following established safety procedures and performing regular maintenance are not optional; they are essential for both operator safety and experimental validity.

Throughput vs. Precision

A 70mm tube furnace is designed for precision, not mass production. While excellent for developing and refining a process, its batch nature and size limit its throughput. It is a tool for discovery and pilot-scale work, not for high-volume manufacturing.

Making the Right Choice for Your Goal

Selecting the right configuration depends entirely on your specific experimental needs.

- If your primary focus is high-purity synthesis (e.g., semiconductors): You need a system with high-vacuum capability, mass flow controllers for gas management, and a high-purity quartz tube.

- If your primary focus is high-temperature processing (e.g., ceramics): A multi-zone furnace with a high-alumina ceramic tube is essential to ensure temperature uniformity above 1200°C.

- If your primary focus is general R&D or teaching: A versatile, single-zone furnace with interchangeable quartz and ceramic tubes offers the best balance of capability and cost-effectiveness.

Ultimately, the tube furnace is a cornerstone of modern materials innovation, enabling the creation and refinement of the very building blocks of technology.

Summary Table:

| Application Area | Key Uses | Key Features |

|---|---|---|

| Material Science | Heat treatment, annealing, sintering, phase transition studies | Precise temperature control, inert atmosphere |

| Chemical Engineering | Catalyst synthesis, calcination, chemical reactions | Controlled gas flow, programmable heating profiles |

| Nanotechnology | Carbon nanotube synthesis, thin-film deposition via CVD | Vacuum capability, reactive gas environments |

| Electronics | Semiconductor fabrication, optical coatings | High purity, uniform heating zones |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Our expertise in R&D and in-house manufacturing ensures you get the perfect fit for your unique needs. Whether you're in material science, chemical engineering, nanotechnology, or electronics, our product line—including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for precision and reliability. With strong deep customization capabilities, we tailor solutions to meet your exact experimental requirements. Contact us today to discuss how we can enhance your research and development processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis