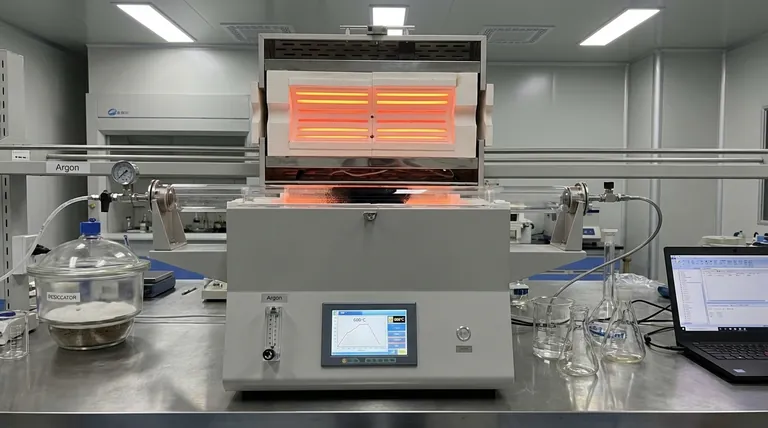

A tube furnace provides two non-negotiable conditions for carbonizing PI-COFs: a strictly inert atmosphere and precise thermal regulation. To successfully convert Polyimide Covalent Organic Frameworks (PI-COFs) into nitrogen-doped mesoporous carbons, the furnace must maintain an oxygen-free environment (typically argon) and execute specific heating protocols, such as ramping at 10°C per minute up to 600°C.

The tube furnace acts as a precision reactor that facilitates the thermal decomposition and reorganization of the organic framework, ensuring the material evolves into a stable graphitic structure rather than oxidizing into ash.

The Necessity of Inert Atmosphere Control

Preventing Material Oxidation

The most critical condition provided by the tube furnace is strict atmosphere protection, utilizing inert gases like argon.

Without this protection, the high processing temperatures would cause the organic framework to react with oxygen.

Instead of carbonizing, the material would simply burn away, destroying the desired graphitic structure.

Facilitating Nitrogen Doping

By excluding oxygen, the furnace creates the ideal environment for the chemical structure to rearrange.

This environment preserves the nitrogen inherent in the PI-COF precursor.

This retention allows for the successful formation of nitrogen-doped mesoporous carbons, which are highly valued for their electronic and catalytic properties.

Thermal Precision and Stability

Controlled Heating Rates

The tube furnace allows for programmable heating ramps, specifically referenced as 10°C per minute.

A controlled ramp is vital to prevent thermal shock to the material.

Gradual heating ensures that volatile components are released systematically, preventing the structural collapse of the framework.

Sustained High Temperatures

The equipment must be capable of reaching and strictly maintaining high temperatures, typically 600°C.

This temperature is the threshold required to drive the thermal decomposition of the PI-COF.

Holding this temperature for a specific duration ensures the complete conversion of the organic polymer into a carbonized state.

Understanding the Trade-offs

Process Speed vs. Structural Integrity

There is a distinct trade-off between the speed of the heating ramp and the quality of the final carbon structure.

While the furnace can heat rapidly, adhering to a moderate rate (like 10°C/min) lengthens the experiment time significantly.

However, rushing this process risks creating a chaotic, non-uniform carbon structure with poor porosity.

Atmosphere Sensitivity

The reliance on a strict inert atmosphere introduces a point of failure: system leaks.

Even a microscopic leak in the tube furnace setup can introduce trace oxygen.

This slight contamination can compromise the purity of the nitrogen-doped carbon, leading to inconsistent experimental results.

Making the Right Choice for Your Experiment

To ensure high-quality carbonization of PI-COFs, you must align your furnace parameters with your material goals.

- If your primary focus is graphitic quality: Prioritize a slower ramp rate and ensure the 600°C hold time is sufficient to allow complete structural reorganization.

- If your primary focus is chemical purity: Double-check the integrity of the argon flow and seals, as the inert atmosphere is the single biggest factor in preventing sample loss to oxidation.

Success in carbonizing PI-COFs relies not just on reaching 600°C, but on how precisely you control the journey there in the absence of oxygen.

Summary Table:

| Parameter | Critical Requirement | Role in PI-COF Carbonization |

|---|---|---|

| Atmosphere Control | Inert Gas (Argon) | Prevents oxidation/ash and facilitates nitrogen doping |

| Heating Rate | 10°C per minute | Prevents thermal shock and structural collapse |

| Max Temperature | 600°C | Drives thermal decomposition and graphitic reorganization |

| Environment | Oxygen-free | Preserves chemical purity and electronic properties |

Elevate Your Advanced Material Synthesis with KINTEK

Precision is the difference between a high-performance graphitic structure and a failed experiment. KINTEK provides the high-performance Tube, Muffle, Vacuum, and CVD systems necessary for sensitive processes like PI-COF carbonization.

Backed by expert R&D and manufacturing, our systems offer the strict inert atmosphere protection and programmable thermal regulation required to ensure consistent, high-purity results. Whether you need standard lab equipment or a custom high-temperature solution, our team is ready to support your unique research goals.

Ready to optimize your carbonization protocols? Contact our experts today to find the perfect furnace for your lab.

Visual Guide

References

- Atsushi Nagai, Atsunori Matsuda. Synthesis and Electrical Property of Graphite Oxide-like Mesoporous <i>N</i>-Carbon Derived from Polyimide-Covalent Organic Framework Templates. DOI: 10.1021/acsomega.5c03968

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a tube furnace in Leidenfrost experiments? Preheating with Precision & Protection

- Why is a high-precision gas flow control system required for vermiculite heat treatment? Ensure Perfect Atmosphere

- Why is a tube furnace with precise temperature control necessary for atmosphere annealing? Master Ceramic Engineering

- What role does a laboratory tube furnace play in the preparation of biochar from date stones? Optimize Pyrolysis.

- What are the advantages of using tubular furnaces? Achieve Precision and Versatility in Thermal Processing

- What role does a tube furnace play in converting nickel precursors? Master Thermal Reduction in Argon Atmospheres

- How does the environmental control of a high-temperature tube furnace affect the calcination of alpha-MoO3 powder?

- What are the main advantages of using a tube furnace? Achieve Precise Thermal Control for Your Lab