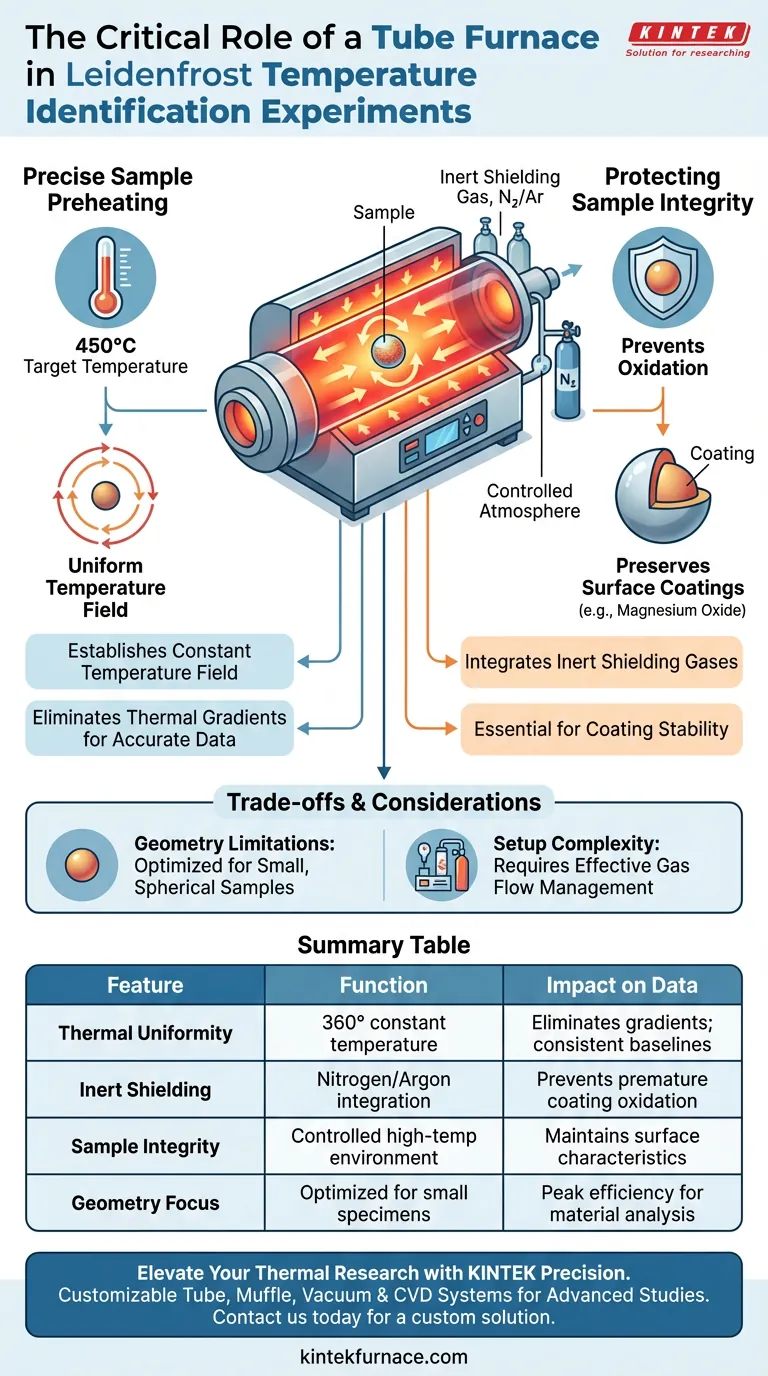

The primary function of a tube furnace in Leidenfrost experiments is to serve as a precise sample preheating device. It establishes a uniform, constant temperature field to heat test specimens—specifically coated spheres—to a critical target temperature (such as 450°C) before the quenching process begins. Beyond simple heating, it creates a controlled environment that is essential for accurate data collection.

In Leidenfrost identification, the tube furnace ensures experimental validity by providing a stable thermal environment that prevents premature oxidation of sensitive sample coatings through the use of inert shielding gases.

The Critical Role of Thermal Uniformity

Creating a Constant Temperature Field

To accurately identify vapor film stability boundaries, the starting conditions of the experiment must be exact. The tube furnace provides a consistent thermal environment, heating the specimen to a preset critical high temperature. This consistency eliminates thermal gradients that could skew data regarding the dynamic quenching process.

360-Degree Heating Distribution

The cylindrical design of the furnace ensures that the test specimen receives heat from all angles. Unlike directional heating sources, this applies consistent heating values across the full 360-degree axis of the sample. This results in optimal heat distribution across the entire cross-section of the sphere.

Protecting Sample Integrity

Facilitating Inert Gas Shielding

A defining feature of the tube furnace in this context is its ability to integrate with inert shielding gases like nitrogen or argon. This controlled atmosphere is a prerequisite for studying high-temperature phenomena without chemical interference.

Preserving Surface Coatings

Many Leidenfrost experiments utilize spherical specimens coated with materials such as Magnesium Hydride or Magnesium Oxide. The shielding gas provided within the furnace prevents the premature oxidation of these coatings during the heating phase. Maintaining the integrity of the coating is vital, as surface characteristics directly dictate the formation and stability of the vapor film.

Understanding the Trade-offs

Geometry Limitations

While the tube furnace offers unmatched uniformity, its elongated, narrow structure limits the size of the specimens you can test. It is strictly optimized for smaller, often spherical samples rather than large or irregularly shaped components.

Setup Complexity

Achieving the necessary protective atmosphere requires more than just the furnace itself. You must manage the flow of inert gases effectively, adding a layer of complexity to the experimental setup compared to standard open-air heating.

Making the Right Choice for Your Experiment

To maximize the utility of a tube furnace in your research, consider your specific experimental needs:

- If your primary focus is surface chemistry: Ensure your gas flow system is perfectly calibrated to prevent even trace oxidation of coatings like Magnesium Oxide.

- If your primary focus is data repeatability: Rely on the multi-zone capabilities or the inherent cylindrical uniformity to guarantee every sample starts at the exact same thermal baseline.

The tube furnace is not merely a heater; it is the control environment that validates the transition boundaries of your vapor film study.

Summary Table:

| Feature | Function in Leidenfrost Experiments | Impact on Data Accuracy |

|---|---|---|

| Thermal Uniformity | 360-degree constant temperature field | Eliminates gradients; ensures consistent starting baselines |

| Inert Shielding | Integration with Nitrogen or Argon gas | Prevents premature oxidation of sensitive sample coatings |

| Sample Integrity | Controlled high-temperature environment | Maintains surface characteristics critical for vapor film stability |

| Geometry Focus | Optimized for spherical/cylindrical specimens | Provides peak efficiency for small-scale material analysis |

Elevate Your Thermal Research with KINTEK Precision

Precise Leidenfrost identification requires more than just heat—it requires a perfectly controlled environment. KINTEK provides high-performance Tube, Muffle, Vacuum, and CVD systems backed by expert R&D and manufacturing. Our customizable laboratory furnaces are designed to help researchers achieve the thermal uniformity and atmosphere control essential for advanced material science and quenching studies.

Ready to optimize your experimental setup?

Contact KINTEK today for a custom high-temp furnace solution and ensure your data integrity with industry-leading thermal engineering.

Visual Guide

References

- Raminta Skvorčinskienė, Vidas Makarevičius. Magnesium Hydride: Investigating Its Capability to Maintain Stable Vapor Film. DOI: 10.3390/en17030661

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is a vertical tube furnace and how does it function? Optimize Material Processing with Precision

- How does a three-tube diffusion furnace ensure the quality of thermal oxidation layers? Achieve High-Efficiency Passivation

- What is the necessity of a precision tube resistance furnace in molten salt electrolysis research? Ensure Unrivaled Precision & Reproducibility!

- What are the unique features of a multi station vacuum tube furnace regarding atmosphere control? Unlock High-Purity Parallel Experiments

- What is the primary purpose of using a tube furnace during the desizing phase? Optimize Carbon Fiber Surface Purity

- What are the key features of a vertical tube furnace? Maximize Efficiency in High-Temperature Labs

- What are the advantages of Quartz Tube Furnaces in terms of customizability and specifications? Unlock Precision and Flexibility for Your Lab

- Why are high-precision industrial quartz tube reactors necessary for butane steam cracking kinetic studies? Ensure Accuracy