At its core, a horizontal electric furnace is engineered for precise thermal processing in highly controlled environments. It is the instrument of choice for applications that demand exceptional temperature uniformity across the sample, particularly when working under a specific atmosphere or in a vacuum.

The horizontal orientation is not an arbitrary design choice; it is a solution specifically tailored to provide a highly stable and uniform heating zone, making it ideal for processing elongated or small-diameter materials with exacting precision.

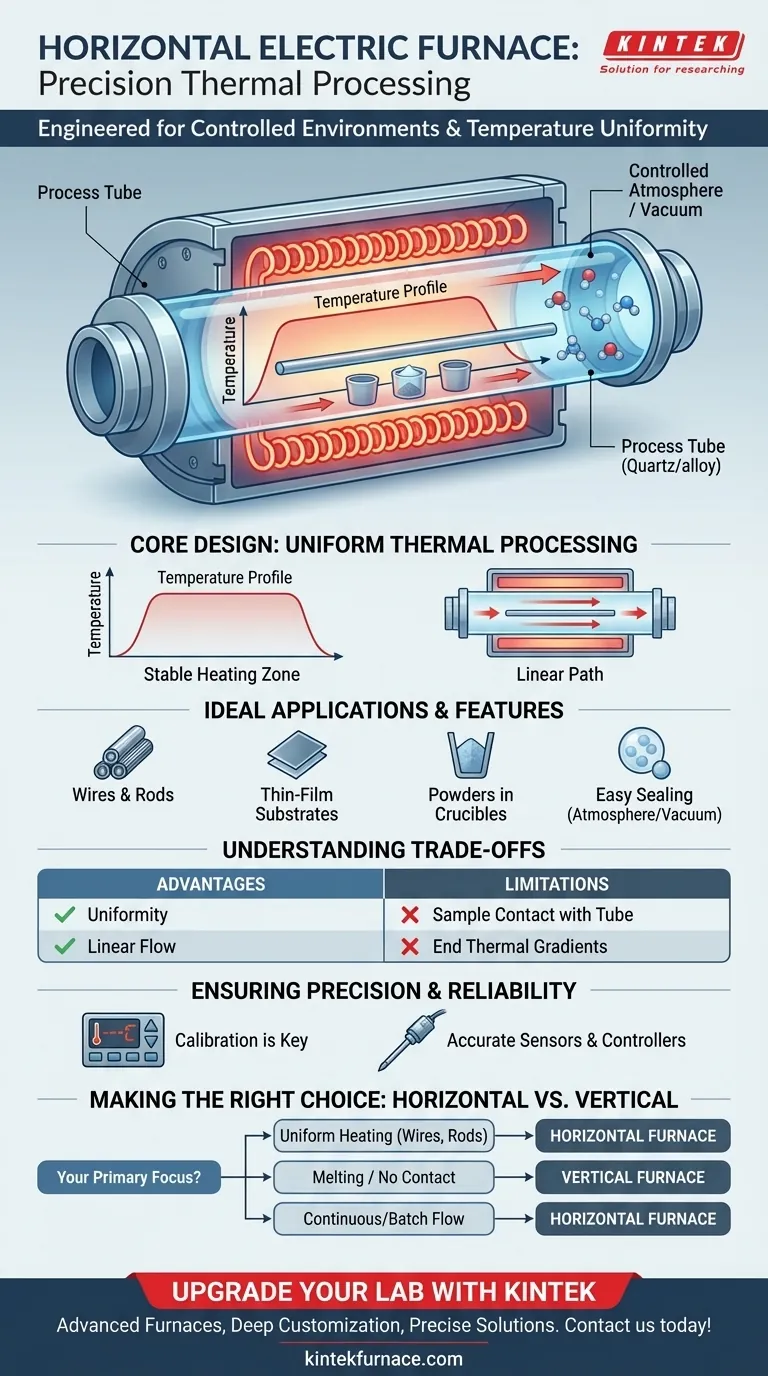

The Core Design Principle: Uniform Thermal Processing

The primary advantage of a horizontal furnace lies in its ability to create a consistent and predictable thermal environment along the length of its heating chamber.

Why the Horizontal Layout Excels

The design typically involves a cylindrical tube, often made of quartz, alumina, or a metal alloy, surrounded by heating elements. This elongated, straight path allows for the creation of a very stable, flat temperature profile in the center of the furnace.

Ideal Sample Types

This configuration is particularly beneficial for treating materials that can be laid flat or passed through the tube. Common examples include wires, rods, small boats or crucibles containing powders, and substrates for film deposition.

Atmosphere and Vacuum Control

The simple, linear geometry of a horizontal tube makes it exceptionally easy to seal. This is critical for applications requiring a controlled atmosphere (like nitrogen or argon to prevent oxidation) or for processes that must be run under a vacuum.

Understanding the Trade-offs

While powerful, the horizontal design is not universally superior. Understanding its limitations is key to selecting the right tool.

Limitation: Gravity and Sample Contact

In a horizontal furnace, the sample rests on the bottom surface of the process tube. This can be a significant drawback if a material melts and must not make contact with the tube, or if a sample must be suspended freely.

Limitation: Thermal Gradients at the Ends

While the central zone is highly uniform, temperature inevitably drops off toward the cooler ends of the tube. This can be a factor for very long samples that extend beyond the optimal flat zone.

Ensuring Precision and Reliability

The value of a horizontal furnace is its precision. Maintaining that precision requires operational discipline.

The Role of Temperature Control

The furnace itself is only part of the system. Its performance is critically dependent on the accuracy of its temperature controller and the placement and health of its temperature sensors (thermocouples).

The Mandate for Calibration

To ensure accurate and repeatable results, periodic calibration of these sensors and controllers is not optional. As noted in technical best practices, even small deviations over time can compromise the material properties you are trying to achieve, negating the primary benefit of using such a precise instrument.

Making the Right Choice for Your Application

Use these principles to guide your decision between a horizontal furnace and other configurations, such as a vertical tube furnace.

- If your primary focus is uniform heating of wires, rods, or thin-film substrates: The horizontal furnace is purpose-built for this and will likely provide the best results.

- If your primary focus is melting materials, growing crystals, or processing samples that must not touch tube walls: A vertical furnace is almost always the superior choice, as it uses gravity to your advantage.

- If your primary focus is processing multiple small samples in a continuous or batch flow: The linear path of a horizontal furnace is often easier to automate and manage.

Ultimately, choosing the correct furnace is about matching the tool's fundamental design strengths to the specific physical demands of your process.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | Precise thermal processing in controlled environments (e.g., vacuum, specific atmospheres) |

| Key Advantage | Exceptional temperature uniformity for elongated or small-diameter materials |

| Ideal Samples | Wires, rods, powders in crucibles, thin-film substrates |

| Limitations | Sample contact with tube bottom; thermal gradients at ends |

| Best For | Applications requiring stable, linear heating and easy sealing |

Upgrade your laboratory's thermal processing with KINTEK's advanced horizontal electric furnaces! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, whether you're working with wires, rods, or substrates. Contact us today to discuss how we can enhance your precision and efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis