At its core, the primary space-saving benefit of a tube furnace is its compact, integrated design. This allows it to occupy a minimal footprint, often fitting on a standard laboratory bench, making it an ideal solution for facilities where floor or counter space is a premium resource.

The true value of a tube furnace isn't just that it's small, but that its compact design is directly responsible for its high thermal efficiency, processing precision, and operational versatility, allowing you to do more within a limited space.

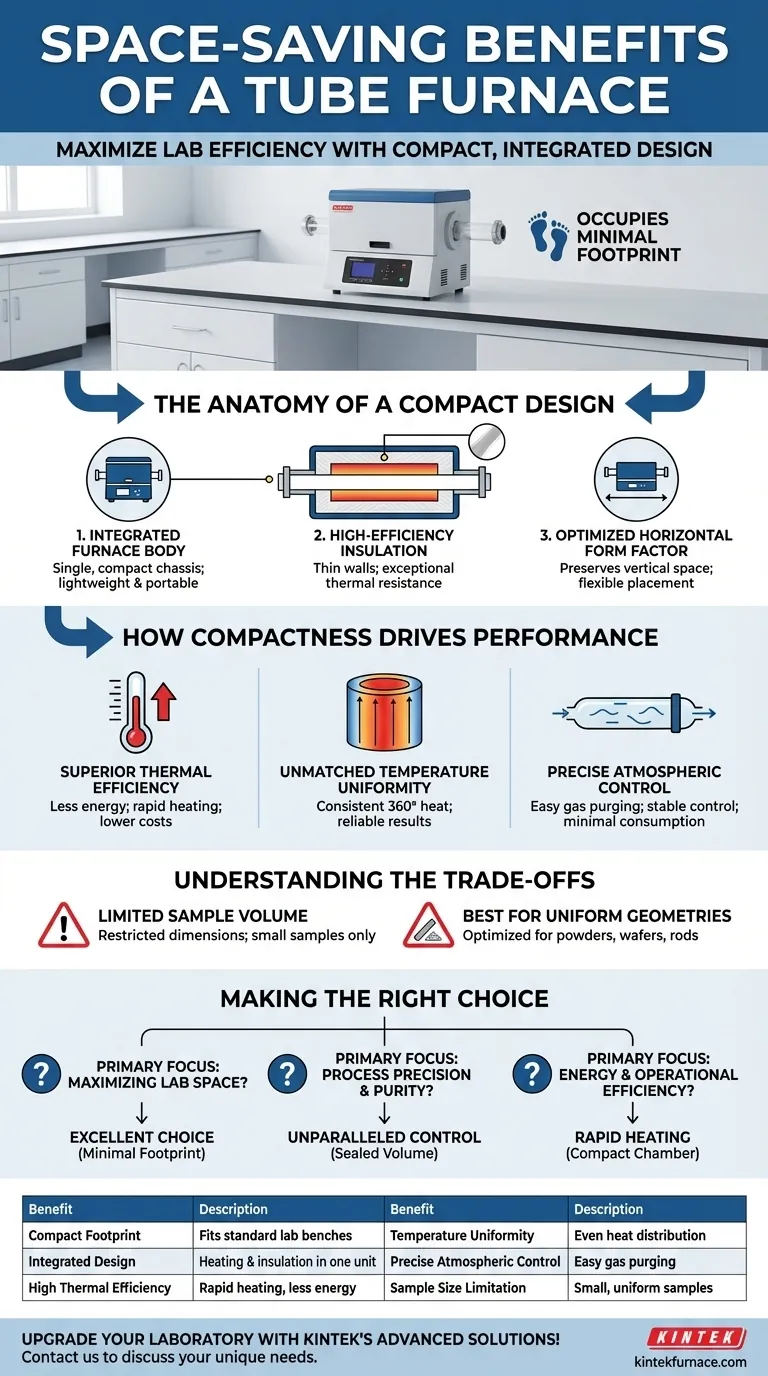

The Anatomy of a Compact Design

A tube furnace achieves its small footprint through deliberate engineering choices that combine the heating chamber, insulation, and shell into a highly efficient, self-contained unit.

Integrated Furnace Body

Modern tube furnaces feature an integrated body where the heating elements and insulation are built directly into a single, compact chassis. This eliminates the need for the large, separate components found in bulkier equipment.

This design is not only space-efficient but also often lightweight, improving portability and ease of placement within a lab.

High-Efficiency Insulation

Tube furnaces leverage advanced insulation materials like high-quality polycrystalline mullite fiber. This material provides exceptional thermal resistance without requiring significant thickness or bulk.

This allows for thinner furnace walls, which directly reduces the overall external dimensions while minimizing heat loss and conserving energy during operation.

Optimized Horizontal Form Factor

The most common horizontal orientation is inherently space-saving. It can be placed on any stable, flat surface, preserving valuable vertical space above it for other equipment or operations.

While vertical models exist for specific applications, the horizontal design offers maximum flexibility for general lab use and easy sample loading.

How Compactness Drives Performance

The small physical volume of a tube furnace is not just a spatial advantage; it is fundamental to its superior performance characteristics compared to larger, less-specialized ovens.

Superior Thermal Efficiency

A smaller, well-insulated chamber requires significantly less energy to reach and maintain high temperatures. This rapid heating capability is a direct result of its compact volume and advanced insulation.

Features like double-layer shells and air insulation further reduce energy consumption, lowering operational costs.

Unmatched Temperature Uniformity

The cylindrical geometry of a tube furnace is ideal for providing uniform heat distribution. The workpiece is subjected to consistent temperatures across its full 360° axis.

This ensures that the entire sample is processed evenly, which is critical for achieving reliable and repeatable results in sensitive applications.

Precise Atmospheric Control

The small, sealed internal volume of a tube makes it exceptionally easy to purge and maintain a specific gas atmosphere.

Whether you need a vacuum, inert, or reactive environment, the limited volume allows for quick gas exchange and stable control with minimal gas consumption.

Understanding the Trade-offs

While highly effective, the design of a tube furnace presents certain limitations that are important to acknowledge.

Limited Sample Volume

The most significant trade-off is sample size. The compact design and tube diameter inherently restrict the dimensions and overall volume of the material you can process at one time.

While some horizontal models offer a larger working volume for multiple small samples, they are not suited for large, bulky components.

Best for Uniform Geometries

Tube furnaces are optimized for samples that fit well within a tube, such as powders, wafers, rods, or small crucibles.

Processing irregularly shaped objects can be challenging and may lead to inefficient heating or contact with the tube walls.

Making the Right Choice for Your Goal

To determine if a tube furnace is the right fit, consider your primary objective.

- If your primary focus is maximizing limited lab space: A tube furnace is an excellent choice due to its minimal footprint and benchtop-friendly design.

- If your primary focus is process precision and purity: The small, sealed volume provides unparalleled control over temperature uniformity and atmospheric conditions.

- If your primary focus is energy and operational efficiency: The combination of a compact chamber and modern insulation ensures rapid heating and lower energy costs.

Ultimately, a tube furnace excels by leveraging its compact form to deliver exceptional thermal performance and process control.

Summary Table:

| Benefit | Description |

|---|---|

| Compact Footprint | Fits on standard lab benches, minimizing space usage |

| Integrated Design | Combines heating elements and insulation in one unit |

| High Thermal Efficiency | Rapid heating with less energy due to small volume |

| Temperature Uniformity | Even heat distribution for reliable results |

| Precise Atmospheric Control | Easy gas purging in sealed tube for purity |

| Sample Size Limitation | Best for small, uniform samples like powders or wafers |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with compact, efficient options like Tube Furnaces, Muffle Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, saving space while boosting performance. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide