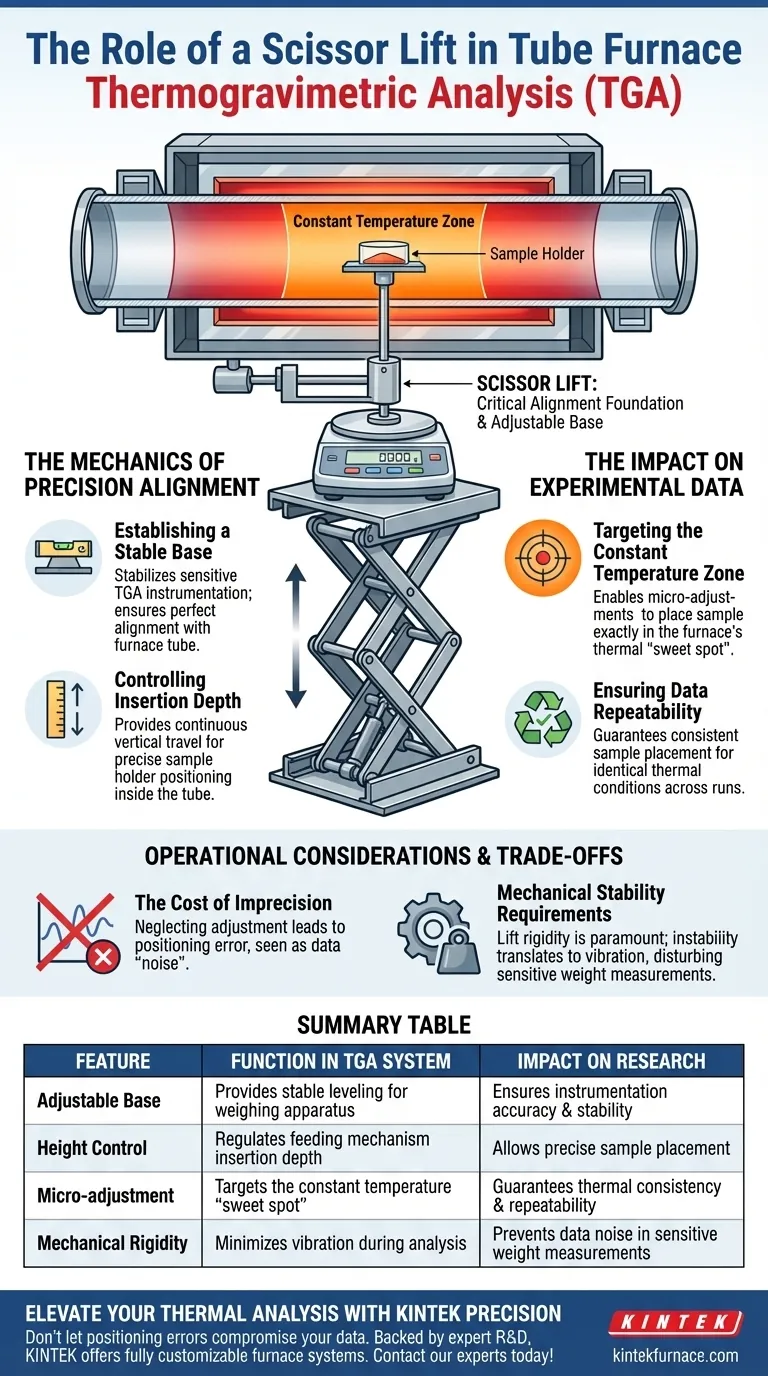

A scissor lift functions as the critical alignment foundation within a tube furnace’s thermogravimetric analysis system. It acts as an adjustable base for the weighing apparatus, providing the mechanical ability to raise or lower the entire setup with smooth, continuous motion. This mechanism allows researchers to control the precise depth of the feeding mechanism inside the furnace tube.

The scissor lift acts as the bridge between mechanical positioning and thermal precision. By enabling micro-adjustments, it ensures the sample resides exactly in the center of the constant temperature zone, which is the defining factor for generating repeatable experimental data.

The Mechanics of Precision Alignment

Establishing a Stable Base

The primary role of the scissor lift is to serve as a leveling platform for the weighing system. It stabilizes the sensitive instrumentation required for thermogravimetric analysis, ensuring the equipment remains perfectly aligned with the furnace tube.

Controlling Insertion Depth

The lift provides the vertical travel necessary to manipulate the feeding mechanism. Through continuous, smooth height adjustments, the operator can dictate exactly how deep the sample holder penetrates the furnace.

The Impact on Experimental Data

Targeting the Constant Temperature Zone

Tube furnaces do not have uniform heat distribution across the entire length of the tube; they have a specific "sweet spot" known as the constant temperature zone. The scissor lift allows the user to physically navigate the sample into the dead center of this zone.

Ensuring Data Repeatability

In pyrolysis or combustion studies, even slight deviations in temperature can alter reaction kinetics. By using the lift to guarantee consistent sample placement, researchers ensure that the thermal conditions are identical for every run, leading to highly repeatable data.

Operational Considerations and Trade-offs

The Cost of Imprecision

While the scissor lift may seem like a passive component, neglecting its adjustment capabilities is a common source of error. Failing to utilize the micro-adjustment feature to find the thermal center often results in "noise" in the data that is actually just positioning error.

Mechanical Stability Requirements

Because the lift supports the weighing system, its own rigidity is paramount. Any instability or play in the scissor mechanism can translate into vibrations that disturb the sensitive weight measurements during the analysis.

Making the Right Choice for Your Goal

To maximize the reliability of your thermogravimetric analysis, consider how you utilize the lift's capabilities:

- If your primary focus is data repeatability: Calibrate the height of the scissor lift before every trial to ensure the sample returns to the exact same geometric coordinates within the tube.

- If your primary focus is accurate pyrolysis: Use the micro-adjustment feature to map the furnace's thermal profile, placing the sample precisely where the temperature is most stable.

By treating the scissor lift as a precision instrument rather than a simple stand, you eliminate spatial variables and ensure your results reflect true chemical behavior.

Summary Table:

| Feature | Function in TGA System | Impact on Research |

|---|---|---|

| Adjustable Base | Provides stable leveling for weighing apparatus | Ensures instrumentation accuracy and stability |

| Height Control | Regulates feeding mechanism insertion depth | Allows precise sample placement in furnace tube |

| Micro-adjustment | Targets the constant temperature "sweet spot" | Guarantees thermal consistency and repeatability |

| Mechanical Rigidity | Minimizes vibration during analysis | Prevents data noise in sensitive weight measurements |

Elevate Your Thermal Analysis with KINTEK Precision

Don't let positioning errors compromise your experimental data. At KINTEK, we understand that research excellence depends on the intersection of mechanical stability and thermal precision.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique laboratory requirements. Whether you need integrated scissor lifts for TGA or bespoke high-temperature configurations, our team is ready to deliver the perfect solution for your workflow.

Ready to achieve repeatable, high-accuracy results? Contact our experts today to discuss your custom furnace needs.

Visual Guide

References

- Beata Brzychczyk, L. J. Sikora. Modernization of a Tube Furnace as Part of Zero-Waste Practice. DOI: 10.3390/su17198940

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the differences between solid and split tube furnaces? Choose the Right Furnace for Your Lab

- What is the primary function of a Drop Tube Furnace in iron ore beneficiation? Unlock High-Precision Thermal Shock.

- What are the disadvantages of a tube furnace? Key Limitations for Industrial and Lab Use

- How does high-temperature heating tape function in conjunction with a tube furnace? Optimize Methanol Cracking.

- What is the primary function of controlled thermal processing for YIG thin films? Unlock Magnetic Order in Spintronics

- What are the disadvantages of quartz tube furnaces? Limitations in Durability and Temperature

- How are tube furnaces utilized in environmental testing? Key Applications for Analysis and Remediation

- How does a tube furnace differ from HPHT methods for Fe2B-HS? Compare Diffusion and Structural Integrity