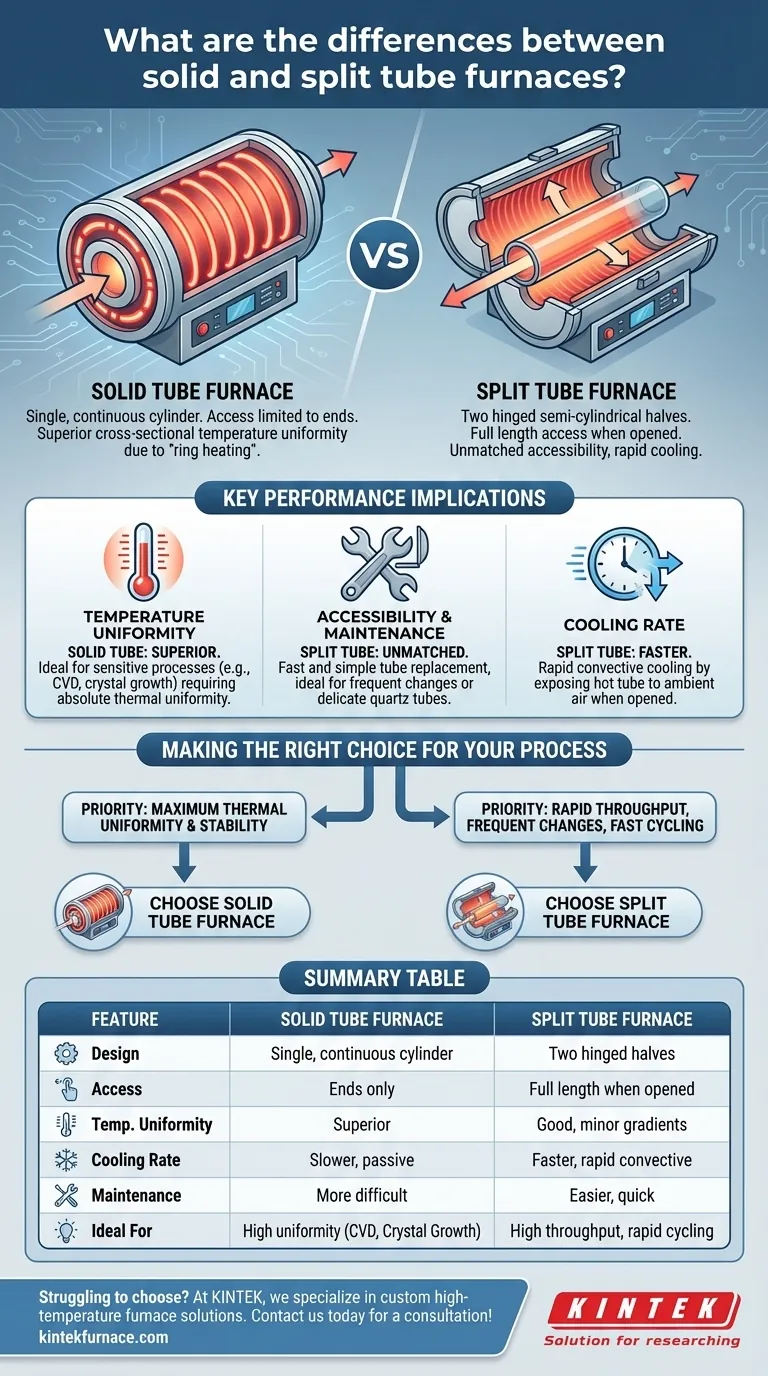

At its core, the difference between a solid and a split tube furnace lies in its physical construction and how you access the internal process tube. A solid tube furnace is a single, continuous cylinder that requires you to slide the work tube and sample in from the ends. In contrast, a split tube furnace is built in two semi-cylindrical halves, allowing it to be hinged open for direct access to the work tube along its entire length.

The decision between a solid and split tube furnace is a fundamental trade-off. You must choose between the superior temperature uniformity of a solid tube design and the enhanced accessibility, faster cooling, and easier maintenance offered by a split tube design.

The Core Design Difference: Access and Construction

The physical build of the furnace directly dictates how you interact with your process and equipment. This is the most immediate and practical difference between the two types.

Solid Tube Furnaces

A solid tube furnace features a heating chamber that is a single, unified cylinder. The heating elements are typically arranged in a ring, fully encircling the process tube.

Access to the chamber is limited to the ends. You must slide your process tube, boat, or crucible into the furnace from one of the openings, which are often sealed with insulating plugs.

Split Tube Furnaces

A split tube furnace is constructed from two separate, semi-cylindrical sections joined by a hinge. This allows the entire furnace body to be opened like a clamshell.

This design provides complete and immediate access to the process tube along its heated length. You can place or remove the tube and its contents without disturbing the end seals or sliding components through the entire heated zone.

Key Performance Implications

The structural differences lead to critical trade-offs in performance, convenience, and operational speed. Your specific application will determine which of these factors is most important.

Temperature Uniformity

Solid tube furnaces generally offer superior temperature uniformity, especially across the tube's cross-section. The "ring heating" design ensures the process tube is heated evenly from all sides.

Split tube designs, which often use heating elements on the top and bottom halves, can create minor temperature gradients between the top, bottom, and sides of the tube.

Accessibility and Maintenance

Split tube furnaces provide unmatched accessibility. This makes replacing a process tube—whether for cleaning, replacement, or to switch materials—a fast and simple task.

In a solid tube furnace, a broken or stuck process tube can be difficult and time-consuming to remove. The ability to open a split tube furnace is a significant advantage for processes that require frequent tube changes.

Cooling Rate

Split tube furnaces cool down much faster. By opening the furnace body, the hot process tube is immediately exposed to ambient air, allowing for rapid convective cooling.

Solid tube furnaces rely on passive cooling, where heat slowly dissipates through the insulation. This results in significantly longer cycle times if your process requires cooling samples back to room temperature.

Understanding the Trade-offs

Neither design is inherently better; they are simply optimized for different priorities. Choosing the wrong one can introduce inefficiencies or compromise the quality of your results.

When to Prioritize a Solid Tube Furnace

A solid tube furnace is the ideal choice for applications where absolute thermal uniformity is the primary concern. This includes processes like sensitive chemical vapor deposition (CVD), single-crystal growth, or annealing specific alloys where even minor temperature gradients can affect outcomes.

When to Prioritize a Split Tube Furnace

A split tube furnace excels in environments that demand speed, flexibility, and easy access. It is superior for rapid thermal cycling, high-throughput sample testing, processes involving in-situ adjustments, or when working with delicate quartz tubes that may require frequent replacement.

The Role of Heating Zones

It's important to distinguish cross-sectional uniformity (solid vs. split) from longitudinal uniformity. Many furnaces, both solid and split, are available with multiple heating zones (e.g., three-zone models). These zones provide excellent temperature control along the length of the furnace, creating a longer, stable hot zone. This feature is independent of the solid or split tube construction.

Making the Right Choice for Your Process

Selecting the correct furnace type requires aligning the furnace's strengths with the non-negotiable requirements of your work.

- If your primary focus is maximum thermal uniformity and process stability: Choose a solid tube furnace for its superior ring heating design.

- If your primary focus is rapid sample throughput and frequent changes: Choose a split tube furnace to minimize downtime between runs.

- If your primary focus is fast heating and cooling cycles: Choose a split tube furnace for its ability to cool down rapidly when opened.

- If your primary focus is using delicate process tubes or frequent maintenance: Choose a split tube furnace for its unparalleled ease of access.

By understanding this core trade-off between uniformity and accessibility, you can confidently select the precise tool required for your scientific or industrial goal.

Summary Table:

| Feature | Solid Tube Furnace | Split Tube Furnace |

|---|---|---|

| Design | Single, continuous cylinder | Two hinged semi-cylindrical halves |

| Access | From ends only | Full length access when opened |

| Temperature Uniformity | Superior, due to ring heating | Good, but may have minor gradients |

| Cooling Rate | Slower, passive cooling | Faster, rapid convective cooling |

| Maintenance | More difficult, time-consuming | Easier, quick tube replacement |

| Ideal For | High uniformity processes (e.g., CVD, crystal growth) | High throughput, rapid cycling, frequent changes |

Struggling to choose between a solid or split tube furnace for your lab? At KINTEK, we specialize in high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer advanced products like Tube Furnaces with deep customization to ensure precise performance—whether you prioritize temperature uniformity or accessibility. Let our experts help you select the perfect furnace to enhance efficiency and results. Contact us today for a consultation!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab