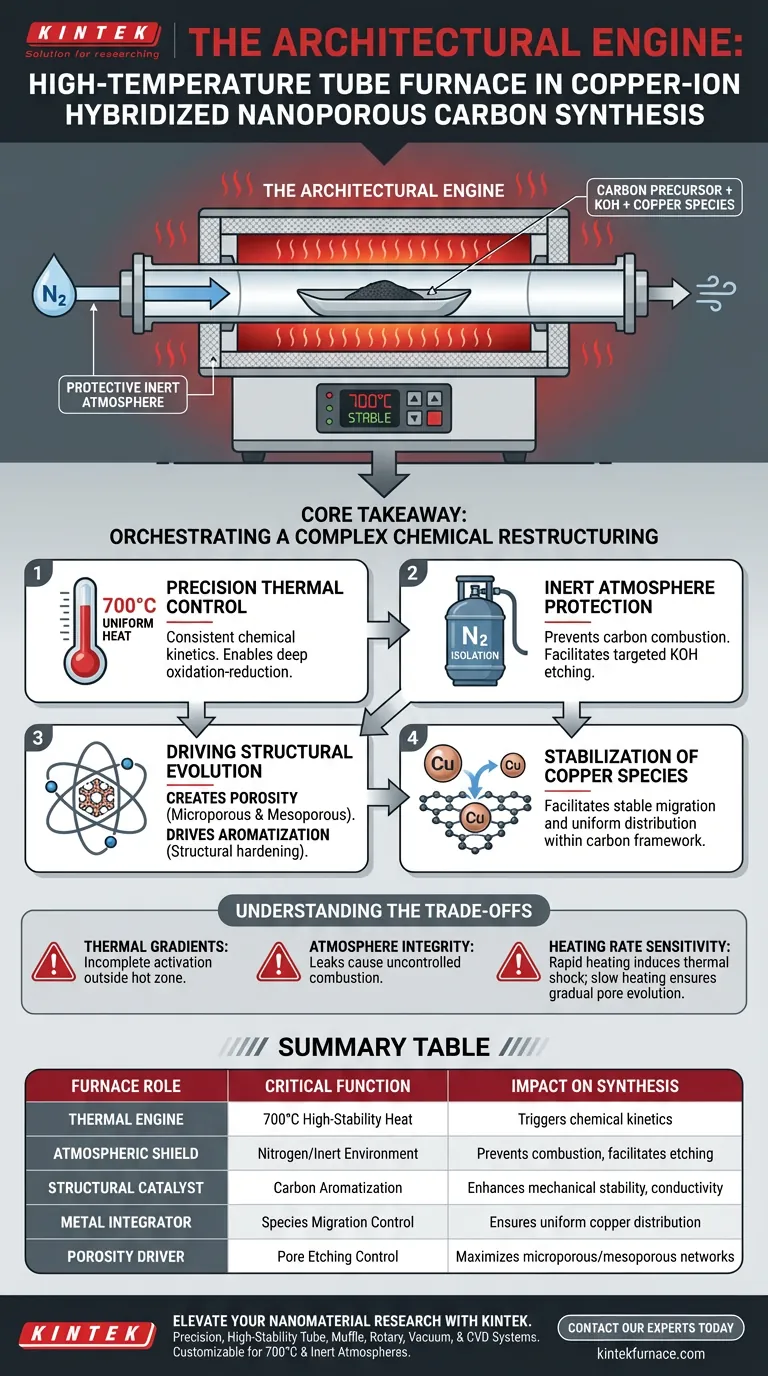

The high-temperature tube furnace acts as the architectural engine for synthesizing copper-ion hybridized nanoporous carbon. It functions by establishing a precisely maintained 700°C thermal environment encased within a protective nitrogen atmosphere. This specific combination of heat and inert gas is required to trigger the deep oxidation-reduction reactions between the activation agent (potassium hydroxide) and the carbon precursor.

Core Takeaway The tube furnace does more than heat the sample; it orchestrates a complex chemical restructuring. It simultaneously drives the formation of high-volume microporous and mesoporous networks while ensuring the stable migration of copper species into a newly aromatized carbon lattice.

Orchestrating the Chemical Environment

Precision Thermal Control

The synthesis requires a strictly controlled temperature, specifically cited as 700°C in your primary context. The tube furnace maintains this temperature with high stability, which is critical for consistent chemical kinetics.

Without this precise thermal energy, the activation energy required for the deep oxidation-reduction reaction would not be met. The furnace ensures that the heat is applied uniformly to the sample, preventing gradients that could lead to heterogeneous material properties.

Inert Atmosphere Protection

The "tube" design allows for the isolation of the sample from ambient air. By purging the chamber with nitrogen (or operating in a high-vacuum state), the furnace prevents the carbon skeleton from simply burning away into ash.

This inert environment allows the potassium hydroxide (KOH) to react solely with the carbon structure to create pores, rather than reacting with atmospheric oxygen. It is the boundary condition that makes the synthesis possible.

Driving Structural Evolution

Creation of Porosity

The primary physical outcome of this activation stage is the creation of surface area. Under the furnace's heat, the chemical reaction etches the carbon material.

This etching process excavates the material, resulting in a large volume of microporous (very small) and mesoporous (medium) structures. This porosity is the defining feature of high-performance nanoporous carbon.

Carbon Aromatization

Beyond just digging holes in the material, the thermal treatment fundamentally changes the chemical structure of the carbon itself.

The heat drives aromatization, transforming the carbon precursors into a more stable, ordered aromatic ring structure. This structural hardening is essential for the material's mechanical stability and electrical conductivity.

Stabilization of Copper Species

For copper-ion hybridized materials, the furnace plays a distinct role in metal integration. The controlled thermal energy facilitates the stable migration of copper species throughout the carbon matrix.

Rather than aggregating or oxidizing unpredictably, the copper ions are distributed and locked into the evolving carbon framework. This ensures the final material retains its hybridized catalytic or electrochemical properties.

Understanding the Trade-offs

The Risk of Thermal Gradients

While tube furnaces are designed for uniformity, the "hot zone" has physical limits. Placing samples outside the central uniform zone can lead to incomplete activation or inconsistent pore sizes.

Atmosphere Integrity

The process is entirely dependent on the purity of the inert atmosphere. Any leak in the tube or contamination in the nitrogen gas supply can catastrophically alter the reaction, turning a controlled activation process into uncontrolled combustion.

Heating Rate Sensitivity

The speed at which the furnace ramps to 700°C can impact the pore structure. Rapid heating may induce thermal shock or seal off pores before they fully develop, while slow heating ensures a more gradual evolution of gases and pore channels.

Making the Right Choice for Your Goal

- If your primary focus is maximizing surface area: Prioritize the precision of the temperature hold at 700°C and the ratio of KOH, as these factors dictate the volume of micropores generated.

- If your primary focus is catalytic activity (Copper integration): Ensure the nitrogen atmosphere is strictly oxygen-free to facilitate the proper migration and reduction of copper species without unwanted oxidation.

Ultimately, the tube furnace provides the thermodynamic stability required to transform a simple mixture of carbon and copper into a highly structured, functionalized nanomaterial.

Summary Table:

| Furnace Role | Critical Function | Impact on Synthesis |

|---|---|---|

| Thermal Engine | 700°C High-Stability Heat | Triggers deep oxidation-reduction for chemical kinetics |

| Atmospheric Shield | Nitrogen/Inert Environment | Prevents carbon combustion; facilitates KOH etching |

| Structural Catalyst | Carbon Aromatization | Enhances mechanical stability and electrical conductivity |

| Metal Integrator | Species Migration Control | Ensures uniform copper distribution within the carbon lattice |

| Porosity Driver | Pore Etching Control | Maximizes development of microporous and mesoporous networks |

Elevate Your Nanomaterial Research with KINTEK

Precision is the difference between simple ash and high-performance nanoporous carbon. Backed by expert R&D and world-class manufacturing, KINTEK provides high-stability Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for the most demanding thermal protocols. Whether you need exact 700°C maintenance or a strictly controlled inert atmosphere, our lab high-temperature furnaces are fully customizable to meet your unique synthesis needs.

Ready to optimize your architectural engine? Contact our technical experts today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Jieni Wang, Shicheng Zhang. Cu-Ion Hybrid Porous Carbon with Nanoarchitectonics Derived from Heavy-Metal-Contaminated Biomass as Ultrahigh-Performance Supercapacitor. DOI: 10.3390/ijms26020569

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the primary function of a tube furnace in materials science and engineering? Unlock Precise High-Temperature Processing

- What role does automation play in horizontal electric furnaces? Boost Precision and Efficiency in Thermal Processing

- How does a high vacuum tube furnace contribute to the carbonization process? Engineered Hard Carbon Synthesis

- What was the original design concept for tube heating furnace systems? Discover the Kettle-Inspired Roots of Modern Heating

- Why is a high-temperature tube furnace necessary for carbonization of biochar? Unlock High-Performance Electrodes

- How does tube furnace cracking compare to fuel furnaces in terms of efficiency? Discover Higher Efficiency and Precision

- Why is atmosphere control critical for lignin carbonization? Expert Tips for High-Temperature Tube Furnace Success

- What role does an industrial-grade tube furnace play in the pyrolysis of nickel-modified molybdenum carbide catalysts?