At its core, the primary function of a tube furnace is to perform high-temperature thermal processing of materials within a tightly controlled and isolated atmospheric environment. It is an indispensable tool in materials science and engineering for synthesis and treatment processes like annealing, sintering, and chemical vapor deposition, where both temperature and the surrounding atmosphere must be precisely managed to achieve specific material properties.

The true value of a tube furnace isn't just its ability to get hot, but its capacity to isolate a sample from the outside world. This control over the processing atmosphere is the critical feature that enables the creation and refinement of advanced materials.

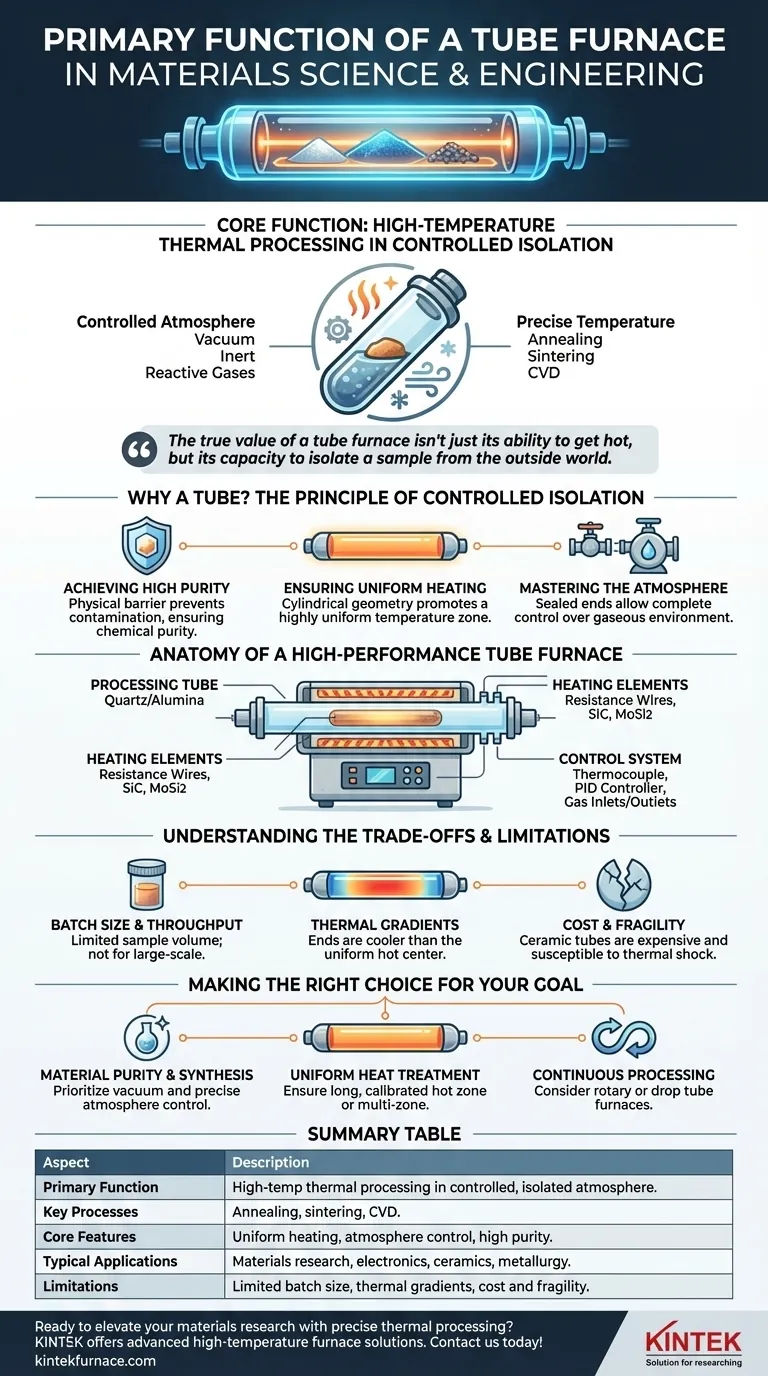

Why a Tube? The Principle of Controlled Isolation

A tube furnace's design is purpose-built to solve one of the biggest challenges in materials science: preventing unwanted reactions. The tubular chamber is the key to creating a pristine, customizable environment separate from the heating elements and ambient air.

Achieving High Purity

The sample is placed inside the tube, which acts as a physical barrier. This prevents contamination from the heating elements or insulation, ensuring the chemical purity of the material being processed.

This separation is critical for sensitive materials where even trace impurities can drastically alter the final electrical, mechanical, or optical properties.

Ensuring Uniform Heating

The cylindrical geometry of the furnace, with heating elements wrapped around the tube's exterior, promotes a highly uniform temperature zone along the central length of the tube.

This uniformity is essential for processes like annealing, where consistent crystal growth or stress relief across the entire sample is required.

Mastering the Atmosphere

The sealed ends of the tube allow for complete control over the gaseous environment around the sample.

This can be a vacuum, created by a pump to remove reactive gases like oxygen. It can also be a specific inert gas like argon or nitrogen to provide a neutral environment, or a reactive gas to intentionally cause a chemical reaction, such as oxidation or carburization.

Anatomy of a High-Performance Tube Furnace

Several key components work in concert to provide this level of precise control. Understanding them reveals how the furnace achieves its function.

The Processing Tube

This is the heart of the furnace. Tubes are typically made from materials like quartz for lower temperatures (up to ~1200°C) or high-purity alumina and other ceramics for higher temperatures (1200°C to 1800°C+). The material is chosen based on temperature requirements and chemical compatibility with the sample.

The Heating Elements

These components generate the heat. Common elements include resistance wires, silicon carbide (SiC) rods, or molybdenum disilicide (MoSi2) rods, which are placed around the process tube to ensure efficient and uniform heat transfer.

The Control System

A thermocouple is inserted near the sample to provide precise, real-time temperature feedback to a PID controller. This system maintains the set temperature with very high accuracy.

Atmosphere is managed via gas inlets and outlets connected to mass flow controllers and vacuum pumps, allowing for programmable environmental conditions.

Understanding the Trade-offs and Limitations

While powerful, a tube furnace is a specialized tool with inherent limitations. It is not the optimal solution for every heating application.

Batch Size and Throughput

The tubular geometry inherently limits the size and volume of the sample. For large-scale industrial production, box furnaces or other configurations are often more suitable due to their larger capacity.

Thermal Gradients

While the central zone is highly uniform, the ends of the tube will always be cooler than the center. This creates a temperature gradient that must be accounted for, often by ensuring the sample is placed entirely within the calibrated uniform hot zone.

Cost and Fragility

High-purity ceramic tubes, especially those made for extreme temperatures or large diameters, can be expensive and are susceptible to thermal shock. Mishandling or excessively rapid heating/cooling cycles can cause them to crack, leading to costly downtime.

Making the Right Choice for Your Goal

Selecting and using a tube furnace effectively requires aligning its capabilities with your specific research or production objective.

- If your primary focus is material purity and controlled synthesis: Prioritize a system with excellent vacuum capabilities and precise atmosphere control to prevent any unwanted chemical reactions.

- If your primary focus is uniform heat treatment like annealing: Ensure the furnace has a long, calibrated hot zone and use a multi-zone furnace for even greater temperature precision over larger samples.

- If your primary focus is continuous processing: Consider specialized variants like rotary or drop tube furnaces that are designed for handling powders and granulates in a continuous flow.

By mastering the principles of controlled atmosphere and temperature, the tube furnace becomes a powerful tool for pushing the boundaries of what materials can do.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | High-temperature thermal processing in a controlled, isolated atmosphere for material synthesis and treatment. |

| Key Processes | Annealing, sintering, chemical vapor deposition (CVD). |

| Core Features | Uniform heating, atmosphere control (vacuum, inert, reactive gases), high purity. |

| Typical Applications | Materials research, electronics, ceramics, metallurgy. |

| Limitations | Limited batch size, thermal gradients at tube ends, cost and fragility of tubes. |

Ready to elevate your materials research with precise thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories in academia and industry. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our tube furnaces can enhance your material synthesis and treatment processes with superior control and reliability!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability