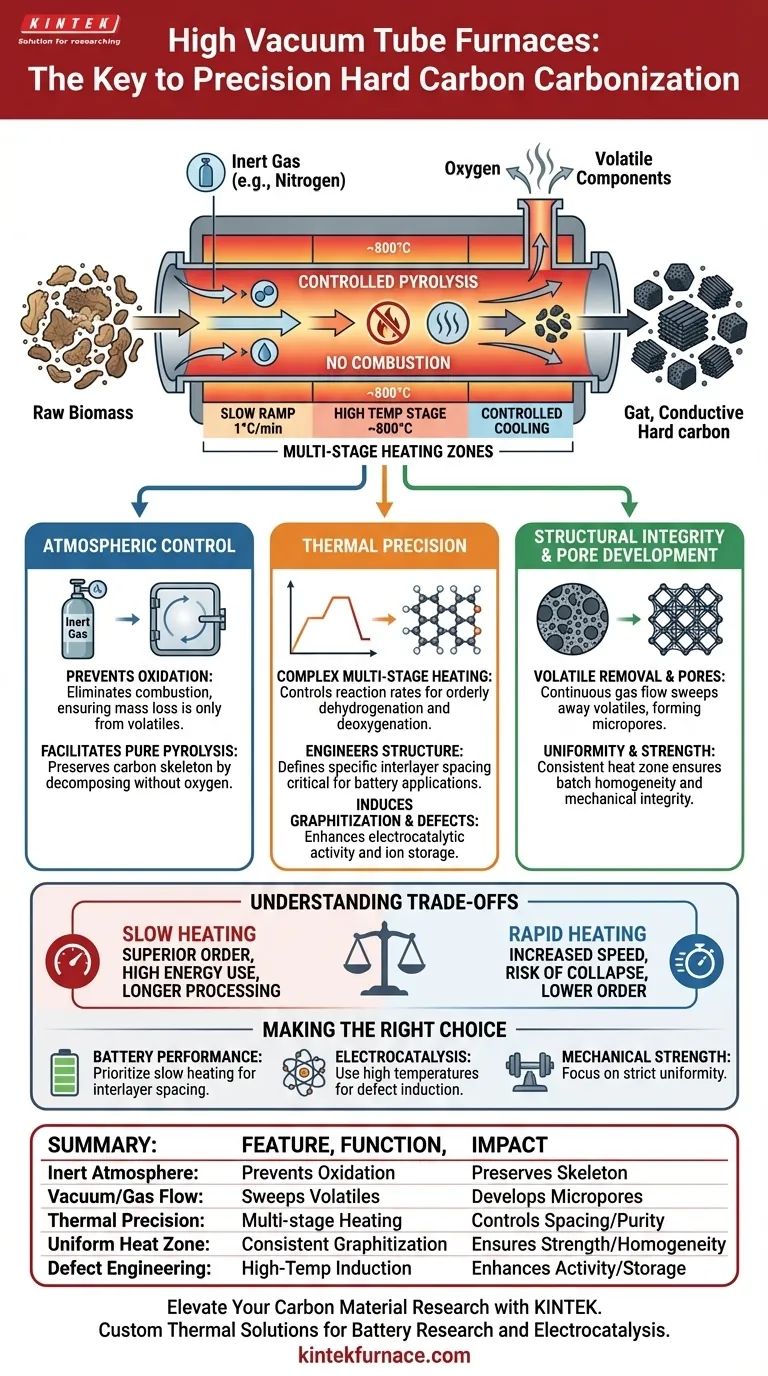

A high vacuum tube furnace acts as the precision reactor necessary to convert organic precursors into structured hard carbon without combustion. By replacing the oxygenated atmosphere with a strictly inert gas environment (typically nitrogen) and executing complex heating profiles, it forces the material to undergo orderly pyrolysis. This process breaks down molecular chains and removes volatiles to engineer a carbon framework with specific interlayer spacing, rather than allowing the biomass to burn away into ash.

Core Takeaway The furnace’s primary value is not just heat, but the decoupling of temperature from oxidation. It facilitates a controlled "molecular surgery"—removing hydrogen and oxygen in a predictable sequence—to transform raw biomass into a conductive, structurally stable hard carbon lattice suitable for advanced energy storage.

The Role of Atmospheric Control

Preventing Oxidative Loss

The fundamental challenge in carbonization is that biomass naturally combusts at high temperatures in air. A high vacuum tube furnace eliminates this by establishing a strictly inert protective environment.

By utilizing high-purity nitrogen or argon, the furnace prevents the oxygen in the air from reacting with the precursor material. This ensures that the mass loss during heating is due to the calculated removal of volatiles, not uncontrolled burning or oxidative degradation.

Facilitating Pure Pyrolysis

In this oxygen-free zone, the material undergoes pyrolysis, where chemical decomposition occurs solely due to thermal energy. This environment allows for the preservation of the carbon skeleton while eliminating non-carbon elements, resulting in a higher purity carbon yield.

Engineering the Carbon Structure via Thermal Precision

Complex Multi-Stage Heating

Creating high-performance hard carbon requires more than a simple ramp to a target temperature. The furnace allows for complex multi-stage heating profiles, which are critical for controlling the rate of chemical change.

The primary reference highlights the necessity of variable gradients, such as slowing the rate to 1°C/min or 2°C/min during critical reaction phases, or accelerating to 10°C/min during stable phases.

Orderly Dehydrogenation and Deoxygenation

These precise heating rates drive orderly dehydrogenation and deoxygenation. Instead of a chaotic release of gases that might crack the material, the furnace allows hydrogen and oxygen to exit the molecular structure systematically.

This controlled removal is essential for forming a hard carbon structure with specific interlayer spacing. This spacing is often the defining characteristic that determines the material's suitability for applications like sodium-ion or potassium-ion batteries.

Defect Engineering and Graphitization

Beyond simple carbonization, the thermal treatment induces the breaking and reorganizing of crosslinked polymer chains. This process initiates graphitization—the formation of a semi-crystalline carbon framework.

Furthermore, high-temperature treatment in these furnaces can induce carbon vacancy defects. These structural imperfections are highly valuable, as they can significantly enhance properties like electrocatalytic activity or ion storage capacity.

Structural Integrity and Pore Development

Volatile Removal and Pore Formation

The continuous flow of inert gas in the tube furnace aids in the removal of volatile components released during pyrolysis. Effectively sweeping these volatiles away is necessary to establish the preliminary micropore structure of the material.

Uniformity and Mechanical Strength

The temperature uniformity of the tube furnace is a critical variable. Uneven heating can lead to structural stresses or inconsistent carbon yields. A uniform thermal zone ensures that the entire batch of precursor material graphitizes evenly, resulting in consistent mechanical strength and structural integrity across the final product.

Understanding the Trade-offs

The Balance of Heating Rates

While rapid heating increases production speed, it risks structural collapse. Conversely, extremely slow heating rates (e.g., 1°C/min) produce superior structural order and specific interlayer spacing but significantly increase energy consumption and processing time.

Atmosphere Sensitivity

The "high vacuum" capability is often used to purge the chamber prior to heating, but the process typically relies on a continuous inert gas flow. If the flow rate is insufficient to sweep away volatiles, they may redeposit as amorphous carbon, clogging the desired pore structure. If the system leaks, even trace oxygen can ruin the electrical conductivity of the final nanowire network.

Making the Right Choice for Your Goal

To maximize the utility of a high vacuum tube furnace for hard carbon synthesis, tailor your parameters to your specific end-goal:

- If your primary focus is Battery Performance (Capacity): Prioritize slow, multi-stage heating rates (1-2°C/min) to ensure specific interlayer spacing and optimal pore structure development.

- If your primary focus is Electrocatalysis: Utilize high temperatures (approx. 800°C+) to induce carbon vacancy defects, which serve as active sites for reactions.

- If your primary focus is Mechanical Strength: Focus on maintaining strict temperature uniformity within the "flat zone" of the tube to ensure the polymer network reorganizes homogeneously.

Ultimately, the high vacuum tube furnace is the tool that transforms biological chaos into electrochemical order through strict atmospheric and thermal discipline.

Summary Table:

| Feature | Function in Carbonization | Impact on Hard Carbon |

|---|---|---|

| Inert Atmosphere | Prevents oxidative combustion | Preserves carbon skeleton and ensures high yield |

| Vacuum/Gas Flow | Sweeps away volatile components | Develops critical micropore structures |

| Thermal Precision | Multi-stage heating profiles | Controls interlayer spacing and chemical purity |

| Uniform Heat Zone | Consistent graphitization | Ensures mechanical strength and batch homogeneity |

| Defect Engineering | High-temperature induction | Enhances electrocatalytic activity and ion storage |

Elevate Your Carbon Material Research with KINTEK

Transform biological precursors into high-performance electrochemical structures with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of battery research and electrocatalysis.

Whether you need to optimize interlayer spacing for sodium-ion batteries or induce specific carbon defects, our furnaces are fully customizable to meet your unique research needs. Ensure strict atmospheric discipline and thermal uniformity for your next breakthrough.

Contact KINTEK Experts Today for a Custom Solution

Visual Guide

References

- Tianqi Yin, Dongdong Han. Preparation of green high‐performance biomass‐derived hard carbon materials from bamboo powder waste. DOI: 10.1002/open.202300178

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the primary applications of lab tubular furnaces in material science and engineering? Precision Heat for Advanced Materials

- What is the primary function of a high-temperature tube furnace in NaF–Na3AlF6 molten salt experiments? Learn more!

- Why is a tube furnace considered essential for metal-zeolite catalysts? Unlock Porosity and Active Sites

- What critical process conditions does a tube atmosphere furnace provide for Sr2CuWO6? Control Atmosphere & Temperature

- What is the significance of using perforated tapered silicone stoppers to seal quartz tube reactors? Achieve Precision.

- How does a high-temperature quartz tube reactor facilitate the synthesis of PC-CNT microspheres? Expert Insights

- What is the key function of a tube furnace for AHSS austenitization? Precision Testing for High-Strength Steel

- What role does a high-temperature tube furnace play in Mo2C synthesis? Master Carbonization Precision