At its core, a lab tubular furnace is a precision instrument designed for thermally processing materials under tightly controlled conditions. Its primary applications in material science and engineering include material sintering and annealing to create dense solids, specialized heat treatments to modify properties, catalyst research in controlled gas environments, and thermal decomposition processes like pyrolysis.

The true value of a lab tubular furnace lies not just in its high-temperature capabilities, but in its ability to create a highly uniform and precisely controlled atmosphere. This control over the processing environment is what makes it indispensable for developing and testing advanced materials where contamination or oxidation would compromise results.

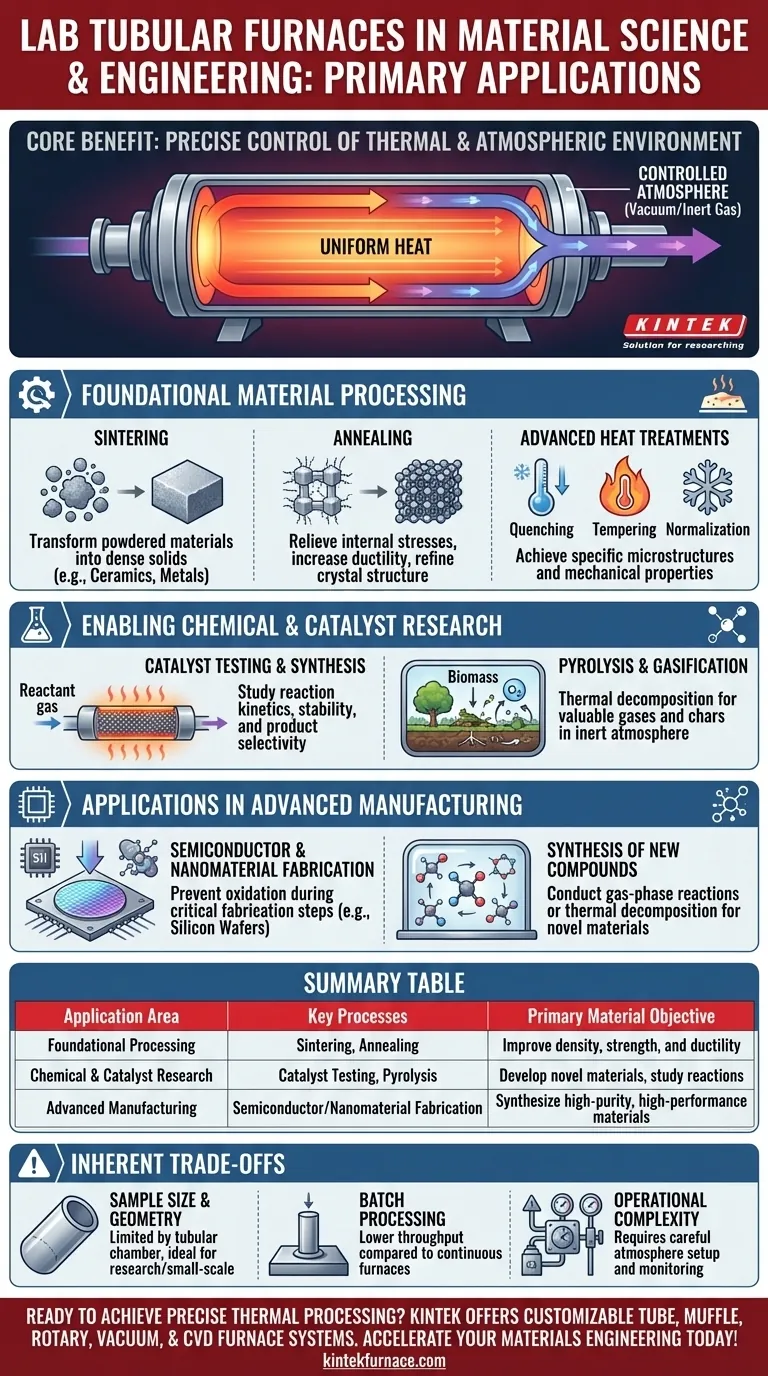

Foundational Material Processing

A tubular furnace provides the uniform thermal environment required for the most fundamental material transformation processes. Its design ensures that heat is applied evenly around the sample's circumference.

Sintering and Annealing

Sintering is the process of heating powdered materials, like ceramics or metals, to a temperature below their melting point. This fuses the particles together, forming a dense, solid mass.

Annealing involves heating a material and then slowly cooling it. This process relieves internal stresses, increases ductility, and refines the crystal structure, making the material less brittle.

Advanced Heat Treatments

Processes like quenching, tempering, and normalization are used to achieve specific microstructures and mechanical properties. The contained, consistent environment of a tube furnace allows for the precise and repeatable heating and cooling cycles these treatments demand.

Enabling Chemical and Catalyst Research

The sealed nature of a tubular furnace makes it an ideal platform for studying chemical reactions and synthesizing new compounds, especially those involving gases or requiring an inert atmosphere.

Catalyst Testing and Synthesis

Researchers can pass reactant gases through the tube over a heated catalyst sample. This setup allows for the direct study of reaction kinetics, catalyst stability, and product selectivity under various temperatures and pressures.

Pyrolysis and Gasification

Pyrolysis is the thermal decomposition of materials, such as biomass, at elevated temperatures in an oxygen-free atmosphere. A tube furnace provides the necessary inert environment to prevent combustion, enabling the production of valuable gases and chars.

Applications in Advanced Manufacturing

The precise atmospheric control offered by tube furnaces is critical for producing high-performance materials where even minimal contamination can cause component failure.

Semiconductor and Nanomaterial Fabrication

These furnaces are widely used in the production of advanced materials like semiconductors and nanomaterials. The controlled atmosphere (vacuum or inert gas) prevents oxidation and other unwanted reactions during critical fabrication steps, such as those for silicon wafers.

Synthesis of New Compounds

The isolated environment is perfect for conducting gas-phase reactions or thermal decomposition experiments. This enables the synthesis of novel compounds that would be impossible to create in a standard furnace exposed to ambient air.

Understanding the Inherent Trade-offs

While incredibly versatile, the design of a lab tubular furnace comes with specific limitations that are important to recognize.

Sample Size and Geometry

The most obvious constraint is the tubular processing chamber. This inherently limits the size and shape of the samples that can be processed, making it ideal for research and small-scale testing rather than mass production.

Batch Processing Limitations

Most lab-scale tube furnaces operate on a batch basis, where one sample or a small group of samples is processed at a time. This results in lower throughput compared to continuous furnaces used in industrial manufacturing.

Operational Complexity

Achieving and maintaining a specific atmosphere—whether high vacuum or a precise gas mixture—requires careful setup and monitoring. This adds a layer of operational complexity compared to a simple air-atmosphere box furnace.

Making the Right Choice for Your Goal

To apply a tubular furnace effectively, you must align the chosen process with your primary material objective.

- If your primary focus is improving material density and strength: Use sintering to transform powdered materials into a solid, cohesive mass.

- If your primary focus is enhancing ductility or reducing brittleness: Employ annealing to relieve internal stresses and refine the material's grain structure.

- If your primary focus is creating highly specific material properties (like hardness): Use controlled heat treatments like quenching and tempering to manipulate the material's microstructure.

- If your primary focus is developing novel materials or catalysts: Leverage the controlled atmosphere for synthesis, pyrolysis, or gas-phase reaction studies where preventing oxidation is critical.

Ultimately, mastering the tubular furnace means mastering control over the thermal and atmospheric environment to precisely engineer the materials of the future.

Summary Table:

| Application Area | Key Processes | Primary Material Objective |

|---|---|---|

| Foundational Processing | Sintering, Annealing | Improve density, strength, and ductility |

| Chemical & Catalyst Research | Catalyst Testing, Pyrolysis | Develop novel materials, study reactions |

| Advanced Manufacturing | Semiconductor/Nanomaterial Fabrication | Synthesize high-purity, high-performance materials |

Ready to achieve precise thermal processing for your material science projects?

Backed by expert R&D and manufacturing, KINTEK offers Tube, Muffle, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique research and development needs. Our lab high-temp furnaces provide the uniform heating and controlled atmospheres essential for sintering, annealing, and advanced synthesis.

Contact us today to discuss how a KINTEK tubular furnace can accelerate your materials engineering!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety