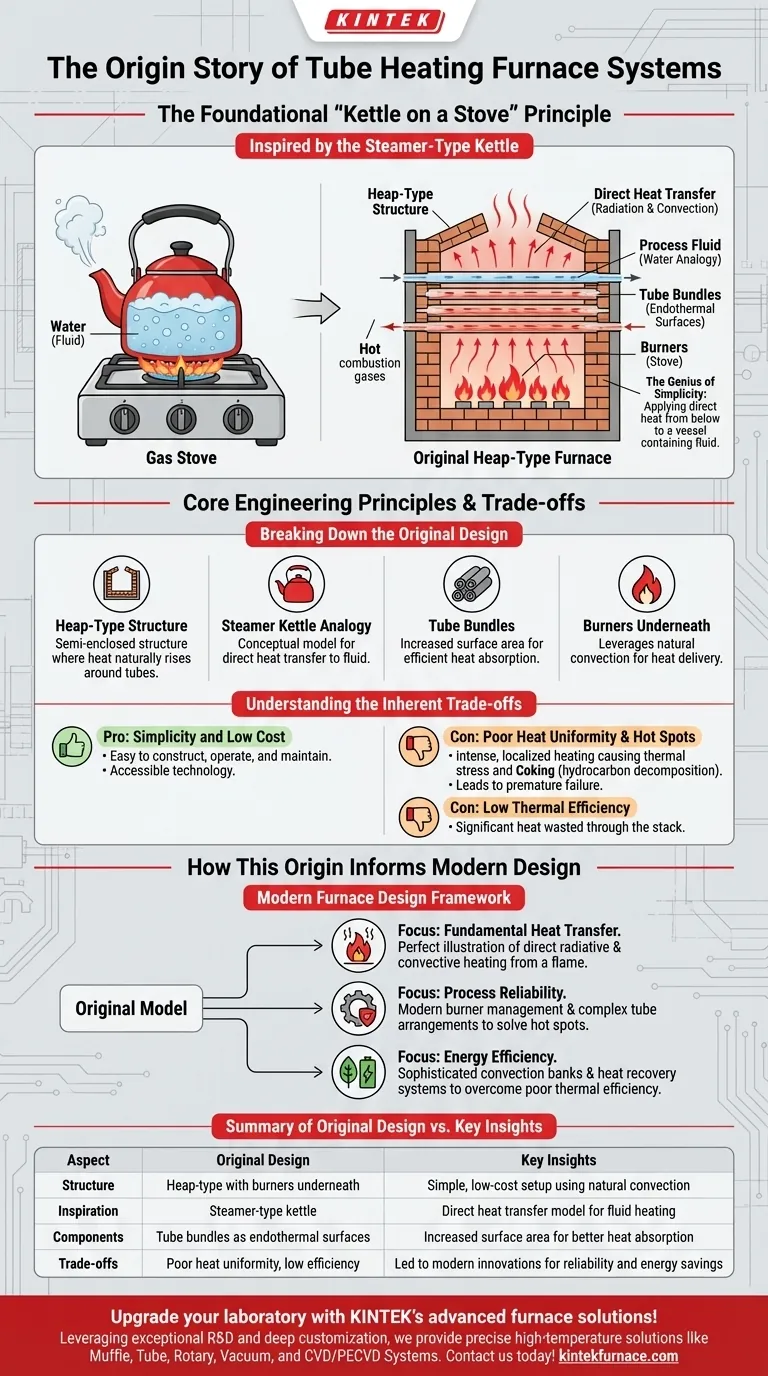

The original tube heating furnace was conceived as a heap-type system, drawing direct inspiration from the concept of a steamer-type kettle. This foundational design positioned burners directly underneath tube bundles, which served as the primary heat-absorbing (endothermal) surfaces to heat the fluid passing through them.

At its core, the first tube heating furnace was a scaled-up industrial version of a simple kettle on a stove. This fundamental principle—applying direct heat from below to a vessel containing a fluid—established the design DNA for all subsequent, more complex furnace technologies.

The Foundational "Kettle on a Stove" Principle

The genius of the original design lies in its simplicity. By breaking it down, we can see the core engineering principles that remain relevant today.

The Heap-Type Furnace Structure

The term heap-type describes the basic layout. It was an open or semi-enclosed structure where heat from the burners naturally rose, "heaping" up around the process tubes much like heat from a campfire.

Inspired by the Steamer Kettle

The conceptual model was a steamer-type kettle. In this analogy, the burners are the stove, the furnace chamber is the kettle, and the fluid inside the tubes is the water being boiled. This simple mental model clarifies the system's primary function: direct heat transfer.

The Role of Tube Bundles

Using tube bundles instead of a single large vessel was a critical innovation. This dramatically increased the surface area exposed to the heat, allowing for more efficient absorption into the process fluid. These are known as endothermal surfaces because they absorb thermal energy.

Burners as the Direct Heat Source

Placing burners underneath the tubes was the most straightforward way to deliver heat. This setup leverages natural convection, as hot combustion gases rise and envelop the tubes, transferring energy primarily through radiation and convection.

Understanding the Inherent Trade-offs

While brilliantly simple, this original design came with significant limitations that drove decades of furnace evolution. Understanding these trade-offs is key to appreciating why modern furnaces are so complex.

Pro: Simplicity and Low Cost

The primary advantage was its simplicity. It was relatively easy and inexpensive to construct, operate, and maintain, making it an accessible technology for early industrial processes.

Con: Poor Heat Uniformity and Hot Spots

Directly exposing tubes to a flame is a double-edged sword. It creates intense, localized heating, or hot spots. This uneven temperature distribution can cause thermal stress on the tube metal and lead to premature failure.

Furthermore, these hot spots can cause the fluid inside the tube to overheat, leading to a process called coking, where hydrocarbons decompose and form insulating layers of carbon inside the tube, drastically reducing efficiency and flow.

Con: Low Thermal Efficiency

The heap-type design was not very efficient. A significant amount of valuable heat energy from the combustion gases would simply rise past the tubes and exit through the stack, completely wasted. Modern furnaces address this with extensive convection sections designed specifically to recover this lost heat.

How This Origin Informs Modern Design

Understanding this simple starting point provides a powerful framework for analyzing any modern furnace system. It allows you to trace complex features back to the fundamental problems they were designed to solve.

- If your primary focus is fundamental heat transfer: See this original model as a perfect illustration of direct radiative and convective heating from a flame source.

- If your primary focus is process reliability: Recognize that modern burner management and complex tube arrangements exist to solve the original problem of hot spots and non-uniform heating.

- If your primary focus is energy efficiency: Acknowledge that sophisticated convection banks and heat recovery systems were developed specifically to overcome the poor thermal efficiency of this first-principles design.

By grasping this origin, you can deconstruct the purpose behind every component in a complex modern furnace.

Summary Table:

| Aspect | Original Design | Key Insights |

|---|---|---|

| Structure | Heap-type with burners underneath | Simple, low-cost setup using natural convection |

| Inspiration | Steamer-type kettle | Direct heat transfer model for fluid heating |

| Components | Tube bundles as endothermal surfaces | Increased surface area for better heat absorption |

| Trade-offs | Poor heat uniformity, low efficiency | Led to modern innovations for reliability and energy savings |

Upgrade your laboratory with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your research and development goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety