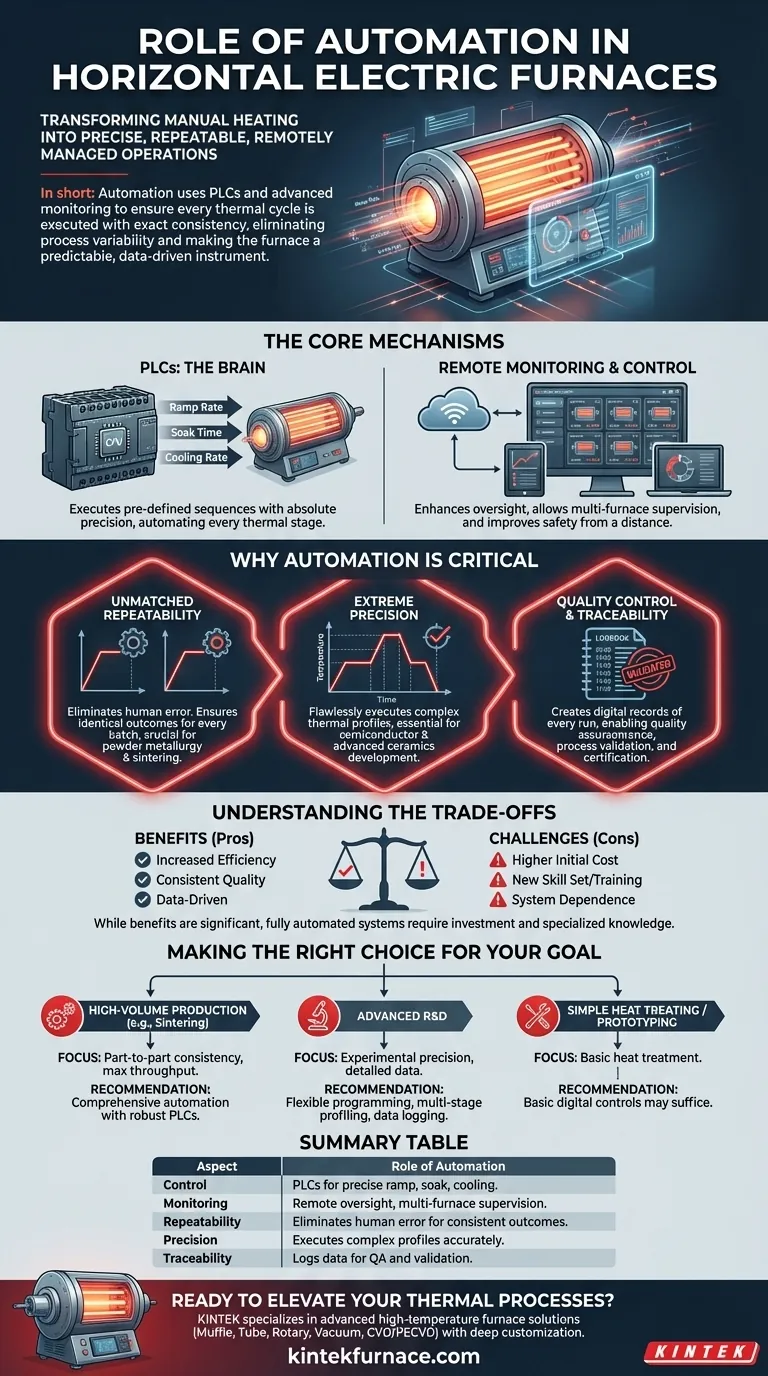

In short, automation in horizontal electric furnaces serves to transform a manual heating process into a highly precise, repeatable, and remotely managed operation. By using programmable logic controllers (PLCs) and advanced monitoring systems, automation ensures that every thermal cycle is executed with exact consistency, which is critical for achieving high-quality results in sensitive applications.

The central role of automation is to eliminate process variability. It moves the furnace from being a simple tool to a predictable, data-driven instrument, ensuring that results from research or production are reliable and traceable, run after run.

The Core Mechanisms of Furnace Automation

To understand the impact of automation, we must first look at the key technologies that enable it. These components work together to take control out of the operator's hands and place it into a reliable, pre-programmed system.

Programmable Logic Controllers (PLCs): The Brain of the Operation

A Programmable Logic Controller (PLC) is a rugged industrial computer that serves as the furnace's central control unit. It executes a pre-defined sequence of commands with absolute precision.

Instead of an operator manually adjusting dials, the PLC automates every stage of the thermal profile. This includes controlling the ramp rate (how fast it heats up), soak time (how long it holds a temperature), and cooling rate.

Remote Monitoring and Control: Enhancing Oversight

Automation platforms provide the ability to monitor and manage the furnace from a central control room or even a remote device. This is far more than a convenience feature.

This capability enhances operational oversight, allowing a single technician to supervise multiple furnaces simultaneously. It also improves safety by reducing the need for personnel to be in close proximity to high-temperature equipment.

Why Automation is Critical for Modern Applications

The drive for automation isn't just about efficiency; it's a direct response to the demands of modern material science and manufacturing. Industries from aerospace to electronics require a level of control that manual operation simply cannot provide.

Achieving Unmatched Process Repeatability

Repeatability is the ability to produce the exact same outcome every time. Automation eliminates the primary source of process variation: human error.

In applications like powder metallurgy or sintering, slight deviations in temperature or time can drastically alter the final product's density and strength. Automation ensures every part in a batch, and every batch over months, receives the identical thermal treatment.

The Demand for Extreme Precision

Many advanced processes, such as semiconductor manufacturing or advanced ceramics development, rely on complex, multi-stage thermal profiles. Precision is key.

An automated system can execute these profiles flawlessly, hitting exact temperature targets without overshooting or undershooting. This precision is fundamental for creating materials with specific, desired microstructures and properties.

Ensuring Quality Control and Traceability

Modern automation systems create an invaluable digital record of every furnace run. They log temperature, time, and other critical process parameters.

This data provides complete traceability, which is essential for quality assurance, process validation, and troubleshooting. For industries requiring certification, this automated documentation is often a non-negotiable requirement.

Understanding the Trade-offs

While the benefits are significant, an objective assessment requires acknowledging the potential downsides of embracing full automation.

Initial Cost and Complexity

Fully automated furnace systems carry a higher upfront investment compared to their manual or semi-automatic counterparts. The hardware and software add to the initial purchase price.

Furthermore, these systems require a different skill set. Staff must be trained to program the PLCs and interpret the data, which can introduce a learning curve for teams accustomed to manual equipment.

Dependence on System Integrity

An automated system is only as reliable as its weakest component. A failed sensor, a software glitch, or a control board issue can bring the entire process to a halt.

Troubleshooting these issues can be more complex than diagnosing a mechanical fault in a simpler furnace. This creates a dependency on reliable electronics and a team capable of diagnosing them.

Making the Right Choice for Your Goal

The appropriate level of automation depends entirely on your specific application and operational priorities.

- If your primary focus is high-volume production (e.g., sintering, ceramics): Comprehensive automation with robust PLCs is critical for ensuring part-to-part consistency and maximizing throughput.

- If your primary focus is advanced research and development: Prioritize systems with flexible programming, multi-stage profiling, and detailed data logging to ensure experimental precision and traceability.

- If your primary focus is simple heat treating or one-off prototyping: A furnace with basic digital controls may be the most cost-effective solution, as the need for absolute repeatability is less critical.

By matching the level of automation to your goals, you can ensure the furnace is a powerful and efficient tool for your specific needs.

Summary Table:

| Aspect | Role of Automation |

|---|---|

| Control | Uses PLCs for precise ramp, soak, and cooling control. |

| Monitoring | Enables remote oversight and multi-furnace supervision. |

| Repeatability | Eliminates human error for consistent outcomes. |

| Precision | Executes complex thermal profiles accurately. |

| Traceability | Logs data for quality assurance and validation. |

Ready to elevate your thermal processes with automated precision? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our automated furnaces can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity