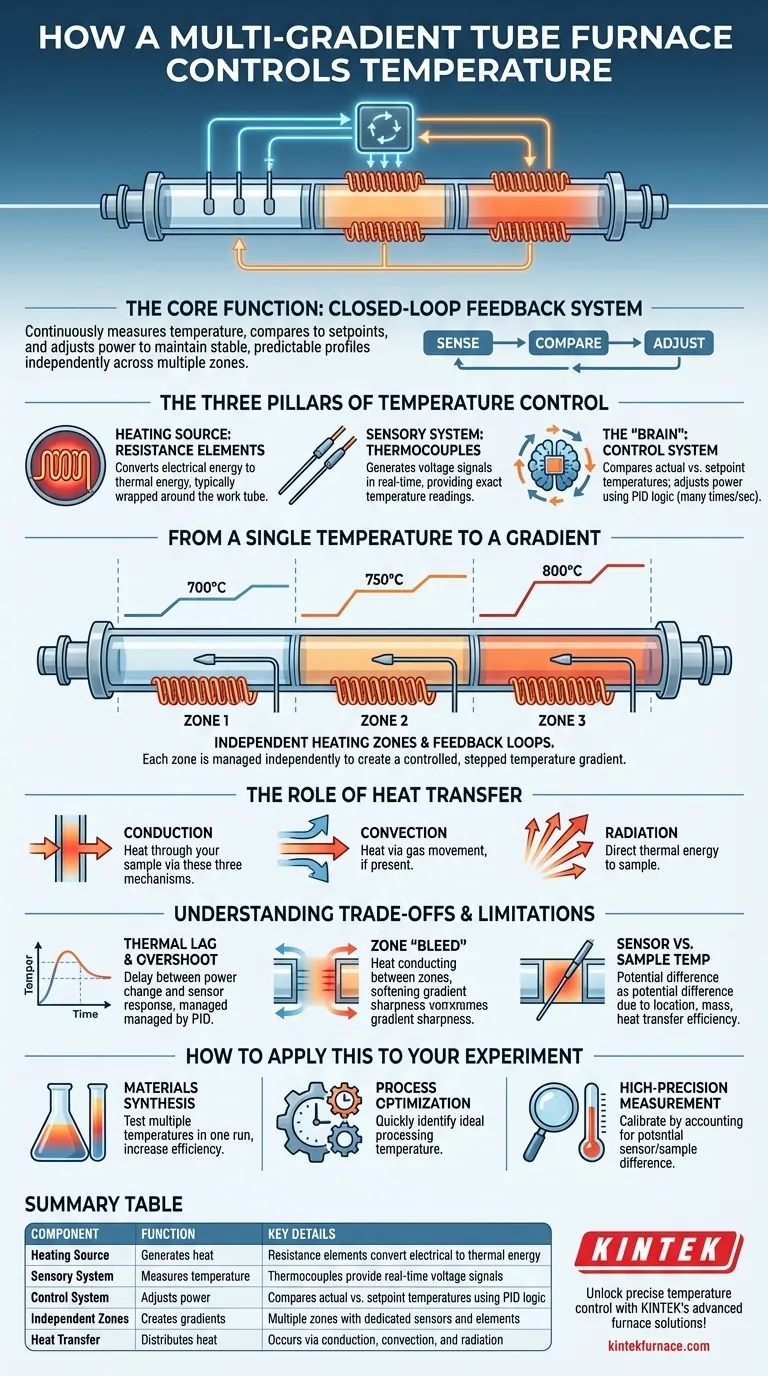

At its core, a multi-gradient experimental tube furnace controls temperature using a sophisticated closed-loop feedback system. It precisely manages multiple independent heating zones along the length of a tube by continuously measuring the temperature in each zone with sensors, comparing these readings to the desired setpoints, and instantly adjusting the electrical power supplied to the corresponding heating elements.

The system's true function is not just to generate heat, but to create and maintain a stable, predictable temperature profile along the furnace tube. This is achieved through a constant, high-speed cycle of sensing, comparing, and adjusting power independently in multiple zones.

The Three Pillars of Temperature Control

To understand how the furnace achieves a precise gradient, we must first look at the three core components working in unison within each temperature zone.

The Heating Source: Resistance Elements

The furnace generates heat using resistance heating elements, typically wrapped around the exterior of the work tube. When the control system sends electrical current to these elements, their natural electrical resistance causes them to heat up, converting electrical energy into thermal energy.

The Sensory System: Thermocouples

To know the temperature, the system relies on sensors, almost always thermocouples. A thermocouple is a simple device made of two different metals joined at one point. This junction produces a tiny voltage that changes predictably with temperature.

This voltage acts as a real-time signal, telling the control system the exact temperature at its specific location.

The "Brain": The Control System

The control system is the central processor that makes intelligent decisions. It constantly performs a simple but critical task for each zone: it compares the temperature signal from the thermocouple (actual temperature) with the target temperature you programmed (setpoint).

If the actual temperature is too low, the controller increases power to the heating elements in that zone. If it's too high, it reduces or cuts the power. This continuous cycle of measuring and adjusting happens many times per second.

From a Single Temperature to a Gradient

The key to a multi-gradient furnace is the multiplication of this control system across several distinct sections of the furnace tube.

The Concept of Independent Heating Zones

A multi-gradient furnace is not one single heater. It is constructed with several sets of resistance heating elements placed sequentially along the length of the tube. Each set constitutes an independent heating zone.

Independent Feedback Loops

Crucially, each of these heating zones has its own dedicated thermocouple and is managed independently by the control system. This means the controller can maintain Zone 1 at 700°C, Zone 2 at 750°C, and Zone 3 at 800°C simultaneously.

Each zone runs its own feedback loop, unaware of the others. The result is a controlled, stepped temperature gradient along the interior of the tube.

The Role of Heat Transfer

Once the heating elements create the temperature on the outside of the tube, that heat must reach your sample on the inside. This occurs through three mechanisms:

- Conduction: Heat travels through the solid material of the tube itself.

- Convection: If a gas is present in the tube, its movement helps distribute heat.

- Radiation: The hot inner wall of the tube radiates thermal energy directly to your sample.

Understanding the Trade-offs and Limitations

While powerful, this system is governed by the laws of physics, which introduces practical considerations you must be aware of.

Thermal Lag and Overshoot

There is a delay between the controller sending more power and the thermocouple registering a temperature increase. An intelligent controller (often using PID logic) anticipates this lag to avoid overshooting the target temperature, which is critical for stability.

Zone "Bleed" and Gradient Sharpness

The heating zones are not perfectly isolated. Heat will naturally conduct along the material of the furnace tube from a hotter zone to an adjacent cooler one. The control system must work constantly to counteract this "bleed," which can slightly soften the sharpness of the gradient between zones.

Sensor Placement vs. Sample Temperature

The system only knows the temperature at the thermocouple's location. The actual temperature of your sample may be slightly different due to its position in the tube, its mass, and the efficiency of heat transfer. For high-precision work, this potential difference must be considered.

How to Apply This to Your Experiment

Understanding how the system works allows you to design better experiments and interpret your results with greater confidence.

- If your primary focus is materials synthesis: Recognize that the gradient allows you to test the effects of multiple precise temperatures on your sample in a single experimental run, dramatically increasing efficiency.

- If your primary focus is process optimization: Use the independent zone controls to quickly identify the ideal processing temperature without having to run multiple, time-consuming experiments.

- If your primary focus is high-precision measurement: Calibrate your setup by accounting for the potential difference between the thermocouple reading and the true temperature at your sample's exact location.

By understanding these principles, you move from simply operating the furnace to truly controlling your experimental environment.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Heating Source | Generates heat | Resistance elements convert electrical energy to thermal energy |

| Sensory System | Measures temperature | Thermocouples provide real-time voltage signals |

| Control System | Adjusts power | Compares actual vs. setpoint temperatures using PID logic |

| Independent Zones | Creates gradients | Multiple zones with dedicated sensors and heating elements |

| Heat Transfer | Distributes heat | Occurs via conduction, convection, and radiation |

Unlock precise temperature control for your experiments with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Tube, Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your research efficiency and accuracy!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety