At their core, tube furnaces are used for their exceptional ability to create a highly uniform and precisely controlled high-temperature environment within a confined, isolated tube. This makes them indispensable for processing materials that require consistent heating and specific atmospheric conditions, such as an inert gas flow, reactive gases, or a high vacuum.

A tube furnace's primary value is not just its ability to get hot, but its power to isolate a sample from the outside world. This creates a perfect micro-environment where temperature, atmosphere, and pressure can be controlled with a precision that other furnace types cannot easily achieve.

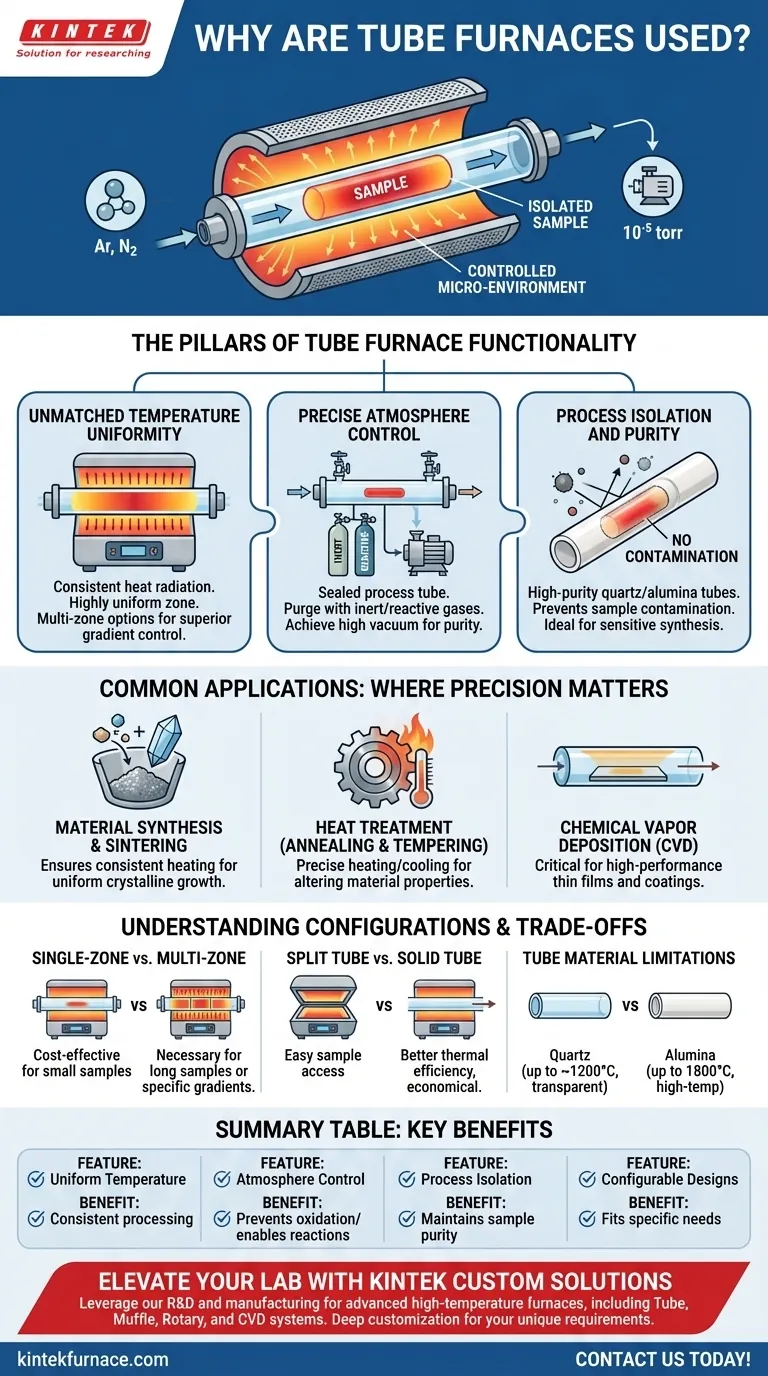

The Pillars of Tube Furnace Functionality

To understand why tube furnaces are so prevalent in research and specialized manufacturing, we must look at the three core capabilities they provide: control over temperature, atmosphere, and contamination.

Unmatched Temperature Uniformity

The cylindrical heating chamber of a tube furnace is designed to radiate heat evenly onto the central process tube. This geometry naturally produces a highly uniform temperature zone in the center of the furnace.

For applications requiring even greater consistency, multi-zone furnaces use multiple, independently controlled heating elements. This allows for superior temperature uniformity over a longer length or the ability to create intentional, stable temperature gradients for advanced processing.

Precise Atmosphere Control

This is a critical differentiator. The sealed process tube allows you to completely control the gaseous environment surrounding your sample.

The furnace can be purged with an inert gas (like argon or nitrogen) to prevent oxidation, filled with a reactive gas for processes like chemical vapor deposition, or evacuated to a high vacuum (down to 10⁻⁵ torr) for purification and degassing. This level of control is achieved with sealed end caps and gas flow management systems.

Process Isolation and Purity

By containing the sample within a high-purity ceramic (alumina) or quartz tube, the furnace ensures the material is not contaminated by the heating elements or the outside air.

This isolation is fundamental for high-purity material synthesis, semiconductor research, and any process where even trace amounts of contaminants could ruin the final product.

Common Applications: Where Precision Matters

The unique capabilities of tube furnaces make them the preferred tool for a range of sensitive thermal processes.

Material Synthesis and Sintering

Creating novel materials or densifying powders into a solid mass (sintering) requires that every part of the sample experiences the exact same temperature profile. The uniformity of a tube furnace prevents weak spots and ensures consistent crystalline growth.

Heat Treatment (Annealing & Tempering)

Altering a material's properties—like making it less brittle (annealing) or harder (tempering)—depends on precise heating and cooling rates. The thermal efficiency and programmable controls of a tube furnace allow for highly repeatable and accurate heat treatment cycles.

Chemical Vapor Deposition (CVD)

CVD is a process used to create high-performance thin films and coatings. A precursor gas is introduced into the tube, where the high temperature causes it to react and deposit a solid layer onto a substrate. This process is entirely dependent on both the stable temperature and the controlled gas atmosphere that only a tube furnace can provide.

Understanding the Trade-offs and Configurations

While powerful, a tube furnace is a specialized tool. Choosing the right configuration involves understanding key trade-offs.

Single-Zone vs. Multi-Zone

A single-zone furnace is simpler and more cost-effective, perfectly suitable for processing smaller samples where the central hot zone is sufficient.

A multi-zone furnace is necessary when processing longer samples or when the absolute best temperature uniformity is non-negotiable.

Split Tube vs. Solid Tube

Split tube furnaces hinge open, allowing for easy placement and removal of the process tube and sample. This is incredibly convenient for complex setups or frequent sample changes.

Solid (or non-split) tube furnaces are more economical and have slightly better thermal efficiency, but require inserting the tube and sample from the end.

Tube Material Limitations

The process tube material dictates the maximum operating temperature. Quartz tubes are excellent for temperatures up to ~1200°C and have the benefit of being transparent. For higher temperatures (up to 1800°C), an alumina ceramic tube is required.

Sample Throughput

Tube furnaces are typically used for batch processing in laboratory and R&D settings. Their sample volume is limited by the tube's diameter, making them less suitable for high-volume, continuous industrial production compared to conveyor or chamber furnaces.

Making the Right Choice for Your Process

Selecting a tube furnace comes down to the specific requirements of your thermal process.

- If your primary focus is material purity and preventing oxidation: A tube furnace with inert gas flow control and high-purity end caps is the ideal solution.

- If your primary focus is creating thin films or coatings: You will need a tube furnace system equipped for Chemical Vapor Deposition (CVD), likely with a gas mixing system and vacuum pump.

- If your primary focus is maximum temperature uniformity over a long sample: A multi-zone tube furnace will provide the most consistent and repeatable results.

- If your primary focus is convenience and frequent sample changes: A split tube design will significantly improve your workflow efficiency and reduce the risk of damaging delicate samples.

Ultimately, a tube furnace is chosen when the integrity of the process environment is just as critical as the temperature itself.

Summary Table:

| Feature | Benefit |

|---|---|

| Uniform Temperature | Ensures consistent heating for reliable material processing |

| Atmosphere Control | Allows use of inert, reactive gases, or vacuum for oxidation prevention and reactions |

| Process Isolation | Maintains sample purity by preventing contamination from external sources |

| Configurable Designs | Options like single/multi-zone and split/solid tubes to fit specific needs |

Ready to elevate your lab's capabilities with a custom tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions tailored for diverse laboratories. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Contact us today to discuss how we can help you achieve precise thermal processing and superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide