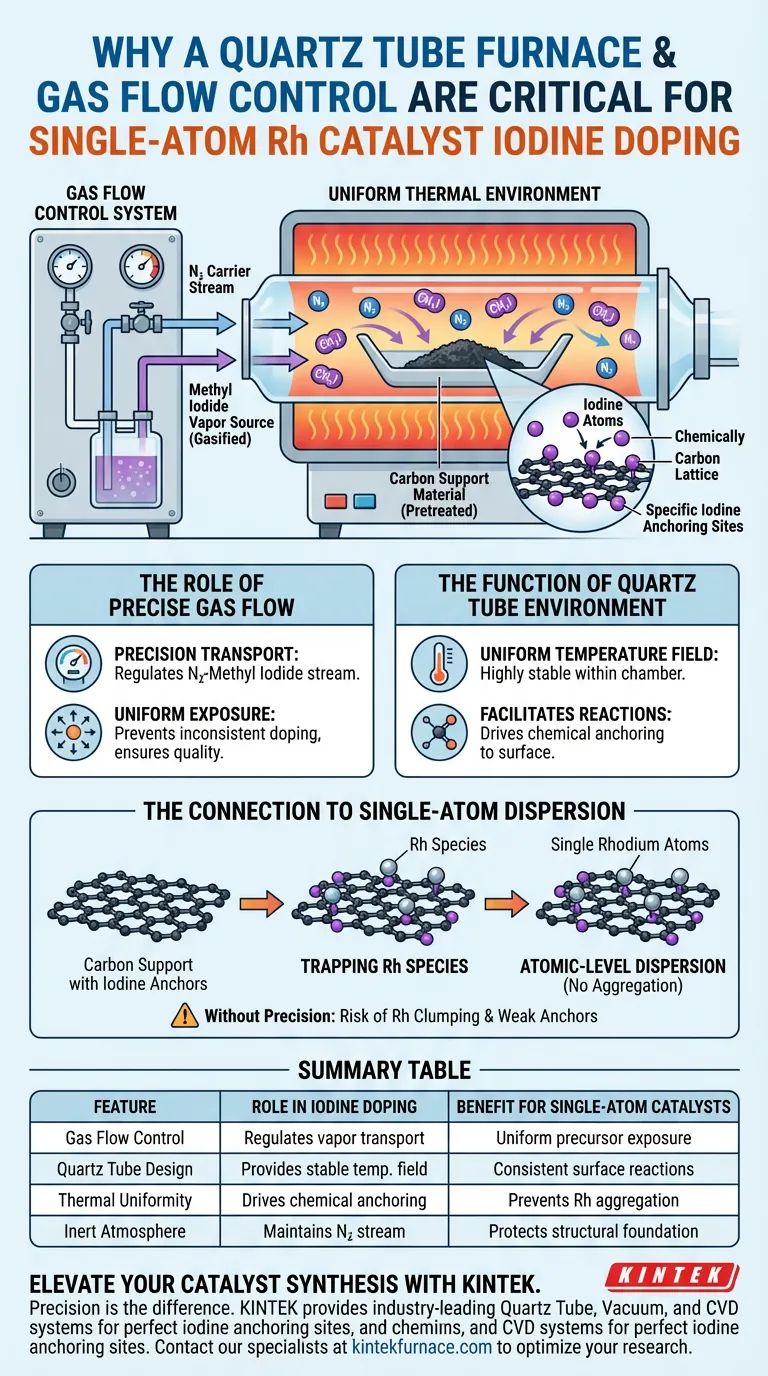

A quartz tube furnace with gas flow control is critical because it enables the precise transport of gasified methyl iodide via a nitrogen stream while maintaining a uniform thermal environment. This combination ensures that iodine atoms thoroughly react with the carbon support to create specific anchoring sites, which are physically necessary to stabilize single rhodium atoms later in the process.

The core purpose of this setup is to engineer a specific surface chemistry rather than simply heating a material. By controlling both the delivery of the iodine precursor and the temperature field, the system establishes a structural foundation that prevents metal atoms from aggregating, ensuring true atomic-level dispersion.

The Role of Precise Gas Flow Control

Transporting the Precursor

In the iodine doping stage, the iodine source is not a solid sitting on the substrate; it is gasified methyl iodide.

The Nitrogen Carrier

A controlled nitrogen stream acts as a carrier vehicle. The gas flow control system ensures this stream transports the methyl iodide vapor to the pretreated carbon support at a consistent, regulated rate.

Ensuring Uniform Exposure

Without precise flow control, the delivery of the precursor would be uneven. This would lead to inconsistent doping across the carbon support, compromising the quality of the final catalyst.

The Function of the Quartz Tube Environment

Creating a Uniform Temperature Field

The quartz tube furnace provides a highly stable and uniform temperature field within the reaction chamber.

Facilitating Surface Reactions

This thermal uniformity is required to drive the reaction between the incoming iodine atoms and the surface functional groups of the carbon support.

Chemical Anchoring

The reaction does not merely deposit iodine; it chemically bonds it. The heat ensures the iodine is firmly anchored to the carbon substrate, creating the specific "landing spots" required for the next stage of synthesis.

The Connection to Single-Atom Dispersion

Building the Structural Foundation

The iodine sites established during this process serve as the structural foundation for the rhodium.

Enabling Atomic Dispersion

These iodine anchors trap the rhodium species. This prevents the metal from clumping together, allowing for the atomic-level dispersion of rhodium atoms, which is the defining characteristic of these high-performance catalysts.

Understanding the Trade-offs

The Risk of Thermal Inconsistency

If the temperature field within the tube is not uniform, the reaction between iodine and the carbon functional groups will be incomplete. This leads to weak anchoring sites and eventually results in rhodium aggregation rather than single-atom dispersion.

The Complexity of Gas Management

While gas flow control offers precision, it introduces variables regarding flow rate and pressure. Incorrect flow settings can either starve the reaction of methyl iodide or oversaturate the surface, both of which degrade the catalyst's final performance.

Making the Right Choice for Your Goal

To ensure the successful preparation of single-atom rhodium catalysts, focus on the following parameters:

- If your primary focus is Uniformity: Ensure your gas flow controller is calibrated to deliver the nitrogen-methyl iodide stream without fluctuation.

- If your primary focus is Stability: Verify that the quartz tube furnace maintains a consistent temperature profile across the entire length of the sample boat to guarantee thorough chemical anchoring.

Mastering the doping environment is the only way to transition from standard metal nanoparticles to true single-atom catalysis.

Summary Table:

| Feature | Role in Iodine Doping Process | Benefit for Single-Atom Catalysts |

|---|---|---|

| Gas Flow Control | Regulates nitrogen-methyl iodide vapor transport | Ensures uniform precursor exposure across carbon support |

| Quartz Tube Design | Provides a highly stable & uniform temperature field | Facilitates consistent surface chemical reactions |

| Thermal Uniformity | Drives chemical anchoring of iodine to carbon | Prevents rhodium aggregation & enables atomic dispersion |

| Inert Atmosphere | Maintains nitrogen carrier stream integrity | Protects the structural foundation of the catalyst |

Elevate Your Catalyst Synthesis with KINTEK

Precision is the difference between metal clumping and true atomic-level dispersion. KINTEK provides industry-leading Quartz Tube, Vacuum, and CVD systems designed specifically for the rigorous demands of single-atom catalyst preparation.

Backed by expert R&D and manufacturing, our customizable high-temperature furnaces deliver the precise gas flow control and thermal uniformity required to engineer perfect iodine anchoring sites.

Ready to optimize your research? Contact our laboratory specialists today to find the ideal thermal solution for your unique synthesis needs.

Visual Guide

References

- Bin Li, Yunjie Ding. Water-participated mild oxidation of ethane to acetaldehyde. DOI: 10.1038/s41467-024-46884-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does an industrial tube furnace facilitate the pack cementation process? Master Precision Diffusion Coatings

- Why is a specialized tube furnace with a steam inlet required for the steam activation of carbon materials?

- Why is a programmable tube furnace required for the synthesis of bulk Cu13Se52Bi35 alloys? Essential Thermal Precision

- What is the primary role of a Tube Furnace in g-C3N4 synthesis? Achieve Precise Thermal Polycondensation

- Why is a high-temperature tube furnace necessary for carbonization of biochar? Unlock High-Performance Electrodes

- What role does a high-temperature tube furnace play in the pore expansion of porous graphene? Expert Material Engineering

- What is the purpose of flushing a tube furnace with high-purity argon for hours? Ensure Pure Silicon Steel Results

- What role does a Horizontal Tube Furnace play in MoP single crystal preparation? Master Thermal Kinetic Control