To ensure high-quality activation, a specialized tube furnace with a steam inlet is required because it provides two non-negotiable conditions: a precise constant temperature zone and a stable, integrated mechanism for steam delivery. Without this specialized equipment, you cannot achieve the controlled gasification necessary to transform biochar into a highly porous, high-surface-area material.

The Core Reality

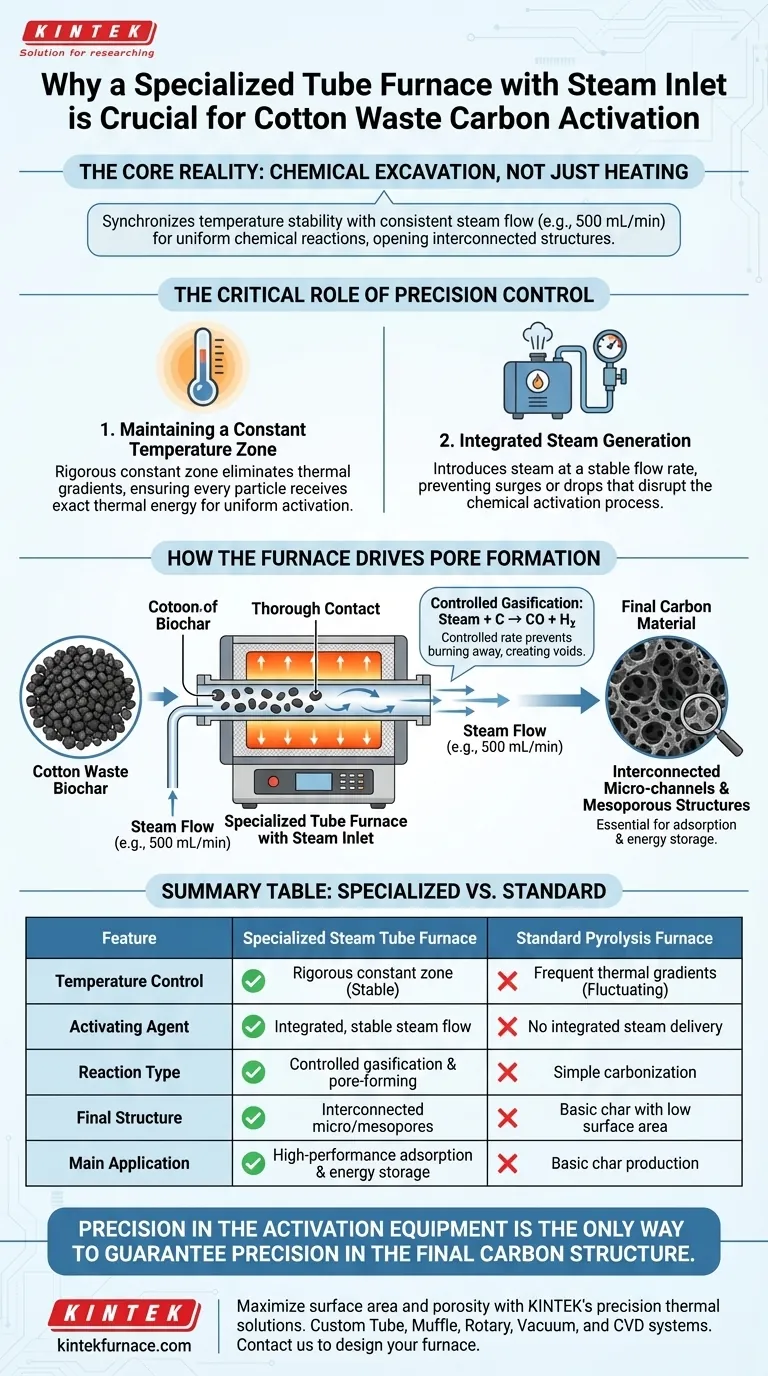

Converting cotton waste into high-performance carbon is not just about heating; it is about chemical excavation. The specialized furnace is essential because it synchronizes temperature stability with a consistent steam flow (e.g., 500 mL/min), ensuring the uniform chemical reactions required to open up interconnected micro-channels and mesoporous structures.

The Critical Role of Precision Control

Maintaining a Constant Temperature Zone

Standard heating equipment often suffers from thermal gradients, where temperature fluctuates across the chamber.

A specialized tube furnace is designed to create a rigorous constant temperature zone. This ensures that every particle of the cotton-derived biochar is exposed to the exact same thermal energy, preventing uneven activation.

Integrated Steam Generation

The key differentiator of this equipment is the integrated steam generation device.

It does not simply dump moisture into the chamber; it introduces steam at a stable flow rate, such as the referenced 500 mL/min. This precision prevents surges or drops in steam pressure that would disrupt the chemical activation process.

How the Furnace Drives Pore Formation

Ensuring Thorough Contact

The design of the tube furnace forces the introduced steam to flow directly through the reaction zone.

This ensures thorough contact between the activating agent (steam) and the biochar surface. Uniform contact is critical for maximizing the surface area of the final material.

Triggering Controlled Gasification

Once the steam contacts the biochar at the correct temperature, it triggers controlled carbon dioxide gasification.

This chemical reaction essentially "eats away" at the carbon skeleton. By controlling the rate of this reaction via the steam inlet, the furnace prevents the material from burning away completely while removing enough carbon to create voids.

Creating Interconnected Structures

The ultimate goal of using this specific apparatus is to engineer the internal architecture of the carbon.

The controlled environment facilitates pore-forming reactions that carve out specific features. These result in interconnected micro-channels and mesoporous structures, which are essential for the material's performance in adsorption or energy storage applications.

Understanding the Trade-offs

Complexity vs. Consistency

While a specialized tube furnace guarantees quality, it introduces operational complexity.

Operators must precisely calibrate the steam flow rate (e.g., maintaining exactly 500 mL/min) and thermal zones. If the steam flow is too aggressive, it can destroy the pore structure; if it is too weak, activation will fail.

Equipment Dependability

Reliance on integrated systems means that if the steam generator fails, the furnace becomes a simple heater.

The interdependence of the heating element and the steam inlet means maintenance is higher than with standard pyrolysis ovens. However, this is the necessary "cost" for achieving advanced porosity.

Making the Right Choice for Your Goal

To determine if this equipment is strictly necessary for your specific project, consider your end goals:

- If your primary focus is high-performance adsorption: You must use the specialized tube furnace to guarantee the formation of interconnected micro-channels and mesopores.

- If your primary focus is basic char production: You may be able to bypass the steam inlet system, but you will sacrifice the specific surface area and pore structure required for advanced applications.

Precision in the activation equipment is the only way to guarantee precision in the final carbon structure.

Summary Table:

| Feature | Specialized Steam Tube Furnace | Standard Pyrolysis Furnace |

|---|---|---|

| Temperature Control | Rigorous constant temperature zone | Frequent thermal gradients |

| Activating Agent | Integrated, stable steam flow (e.g. 500 mL/min) | No integrated steam delivery |

| Reaction Type | Controlled gasification & pore-forming | Simple carbonization |

| Final Structure | Interconnected micro-channels & mesopores | Basic char with low surface area |

| Main Application | High-performance adsorption & energy storage | Basic char production |

Maximize the surface area and porosity of your carbon materials with KINTEK’s precision thermal solutions. Backed by expert R&D and world-class manufacturing, we offer specialized Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific steam activation requirements. Whether you are scaling up biochar research or optimizing industrial adsorption materials, KINTEK provides the consistent thermal zones and integrated steam delivery systems necessary for high-performance results. Contact us today to design your custom high-temperature furnace and achieve superior material architecture.

Visual Guide

References

- Chaiyan Chaiya, Piyaporn Kampeerapappun. Enhancing the Sustainability of Cotton Spinning Mill Waste Through Thermochemical Processes: Converting Waste into Carbon Materials. DOI: 10.1021/acsomega.5c05007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are tube furnaces commonly used for? Essential for Controlled Heat & Material Synthesis

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What materials can be processed in tubular furnaces? Versatile Solutions for Metals, Ceramics, and More

- Why is annealing in a tube furnace essential for rGO-NiO-ZnO-400? Optimize Your Catalyst Synthesis

- How does oxygen atmosphere treatment in a tube furnace affect titania nanotubes? Optimize Your Nanostructure Performance

- Why is a continuous flow of high-purity nitrogen necessary during the pyrolysis of carbon materials in a tube furnace?

- How does a Tube Resistance Furnace facilitate biomass pyrolysis? Achieve High-Purity Biochar Production

- What role does a tube furnace play in the physical synthesis of metal nanoparticles? Master Phase Transformation