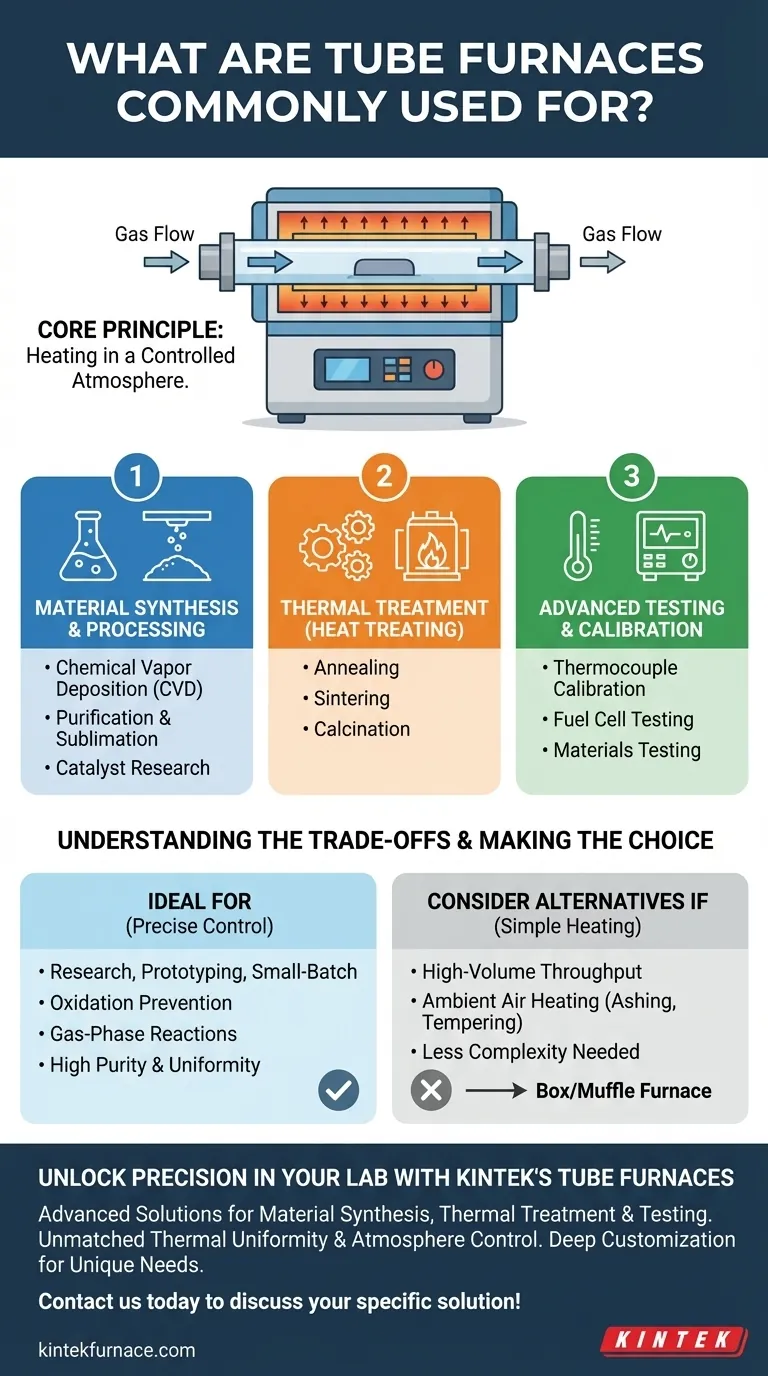

In short, tube furnaces are specialized ovens used to heat samples within a contained tube, allowing for precise thermal processing in a tightly controlled atmosphere. Their primary applications fall into three main categories: material synthesis, thermal treatment (heat treating), and advanced materials testing.

The essential value of a tube furnace is not just its ability to achieve high temperatures, but its unique capacity to isolate a sample from the ambient air. This control over the atmosphere—whether vacuum, inert, or reactive gas—is the reason it is indispensable for processes where purity, oxidation, or specific chemical reactions are critical factors.

The Core Principle: Heating in a Controlled Atmosphere

Unlike a conventional oven that heats in ambient air, a tube furnace's design is centered around a ceramic or metal process tube. This simple design feature is the key to its versatility.

Achieving High Thermal Uniformity

The cylindrical geometry of the heating chamber, combined with high-quality heating elements, ensures that the sample is heated evenly from all sides. This thermal uniformity is crucial for consistent material properties and reliable experimental results.

Mastering the Atmosphere

The sealed tube allows operators to completely control the gaseous environment around the sample. This is typically achieved in one of three ways:

- Vacuum: Air is pumped out to prevent any atmospheric reactions, particularly oxidation.

- Inert Gas: The tube is flushed with a non-reactive gas like argon or nitrogen to displace oxygen and other contaminants.

- Reactive Gas: A specific gas is introduced to intentionally cause a chemical reaction on the sample's surface, a process central to chemical vapor deposition.

Preventing Unwanted Reactions

By removing oxygen and moisture, tube furnaces are the standard for processing air-sensitive materials. This prevents oxidation, unwanted phase changes, and contamination, ensuring the integrity of the final product or experiment.

Key Applications by Function

The ability to control both temperature and atmosphere makes tube furnaces a cornerstone tool in research and specialized manufacturing. Applications are best understood by their function.

Material Synthesis and Processing

This is where new materials are created or existing ones are purified.

- Chemical Vapor Deposition (CVD): A reactive gas is passed over a heated substrate, depositing a thin film. This is fundamental in producing semiconductors and materials like graphene.

- Purification & Sublimation: Heating materials under vacuum can vaporize and separate impurities, leaving behind a purified substance.

- Catalyst Research: The furnace provides a controlled environment to test the performance and durability of catalytic materials under specific gas flows and temperatures.

Thermal Treatment (Heat Treating)

This involves modifying the microstructure and properties of a material using carefully controlled heating and cooling cycles.

- Annealing: Heating a material to relieve internal stresses, making it softer and more workable.

- Sintering: Heating powdered material below its melting point to cause the particles to bond together, forming a solid, dense object. This is common in ceramics and metallurgy.

- Calcination: Heating a material to drive off volatile substances, such as water or carbon dioxide, to induce a phase transition.

Advanced Testing and Calibration

The precision of a tube furnace is essential for applications that require stable and repeatable conditions.

- Thermocouple Calibration: Thermocouples are calibrated against a known standard in a highly stable and uniform thermal environment.

- Fuel Cell Testing: Tube furnaces are used to simulate the high-temperature operating conditions of solid oxide fuel cells (SOFCs) to test material performance and longevity.

- Materials Testing: Aerospace and other high-tech industries use tube furnaces to test how metals, ceramics, and composites behave under extreme temperatures in specific atmospheres.

Understanding the Trade-offs

While powerful, a tube furnace is not always the right tool for every heating task. Objectivity requires acknowledging its limitations.

Sample Size and Throughput

The diameter of the process tube inherently limits the size and volume of the sample. Tube furnaces are ideal for research, prototyping, and small-batch production, but they are not designed for high-volume industrial throughput.

Complexity and Cost

Achieving and maintaining a controlled atmosphere requires additional equipment, such as vacuum pumps, gas mixers, and flow controllers. This adds a layer of complexity and cost compared to a simple box furnace that operates in air.

When a Simpler Furnace Suffices

If your only goal is to heat a sample in ambient air—for example, in ashing processes or simple tempering—a less complex and more cost-effective box or muffle furnace is often the superior choice. The tube furnace's primary advantage is lost if atmospheric control is not needed.

Making the Right Choice for Your Process

Your specific goal determines whether the unique capabilities of a tube furnace are necessary.

- If your primary focus is material synthesis, preventing oxidation, or running gas-phase reactions: A tube furnace is essential for its unparalleled atmospheric control.

- If your primary focus is high-volume heat treatment in air: A larger, industrial batch or conveyor furnace would be a more practical solution.

- If your primary focus is high-purity analysis or component calibration: The thermal uniformity and environmental stability of a tube furnace are non-negotiable for generating reliable data.

- If your primary focus is simple heating of non-sensitive materials: A standard box furnace is likely the more efficient and economical choice.

Ultimately, selecting a tube furnace is a decision to prioritize precise environmental control and thermal uniformity for sensitive, high-value processes.

Summary Table:

| Application Category | Key Uses |

|---|---|

| Material Synthesis | CVD, purification, catalyst research |

| Thermal Treatment | Annealing, sintering, calcination |

| Advanced Testing | Thermocouple calibration, fuel cell testing, materials testing |

Unlock Precision in Your Lab with KINTEK's Tube Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you're in material synthesis, thermal treatment, or advanced testing, our tube furnaces deliver unmatched thermal uniformity and atmosphere control to enhance your research and production efficiency. Contact us today to discuss how we can tailor a solution for your specific needs!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety