In short, a tubular furnace can process an exceptionally wide range of materials, including most metals, ceramics, polymers, semiconductors, and various carbon-based substances. Their suitability comes from their ability to provide precise, uniform heating in a tightly controlled atmosphere, which is critical for both research and specialized industrial production.

The key determining factor is not the furnace itself, but its specific configuration. A material's compatibility depends entirely on the furnace's maximum temperature, its atmosphere control capabilities (air, vacuum, or inert gas), and the chemical inertness of the process tube.

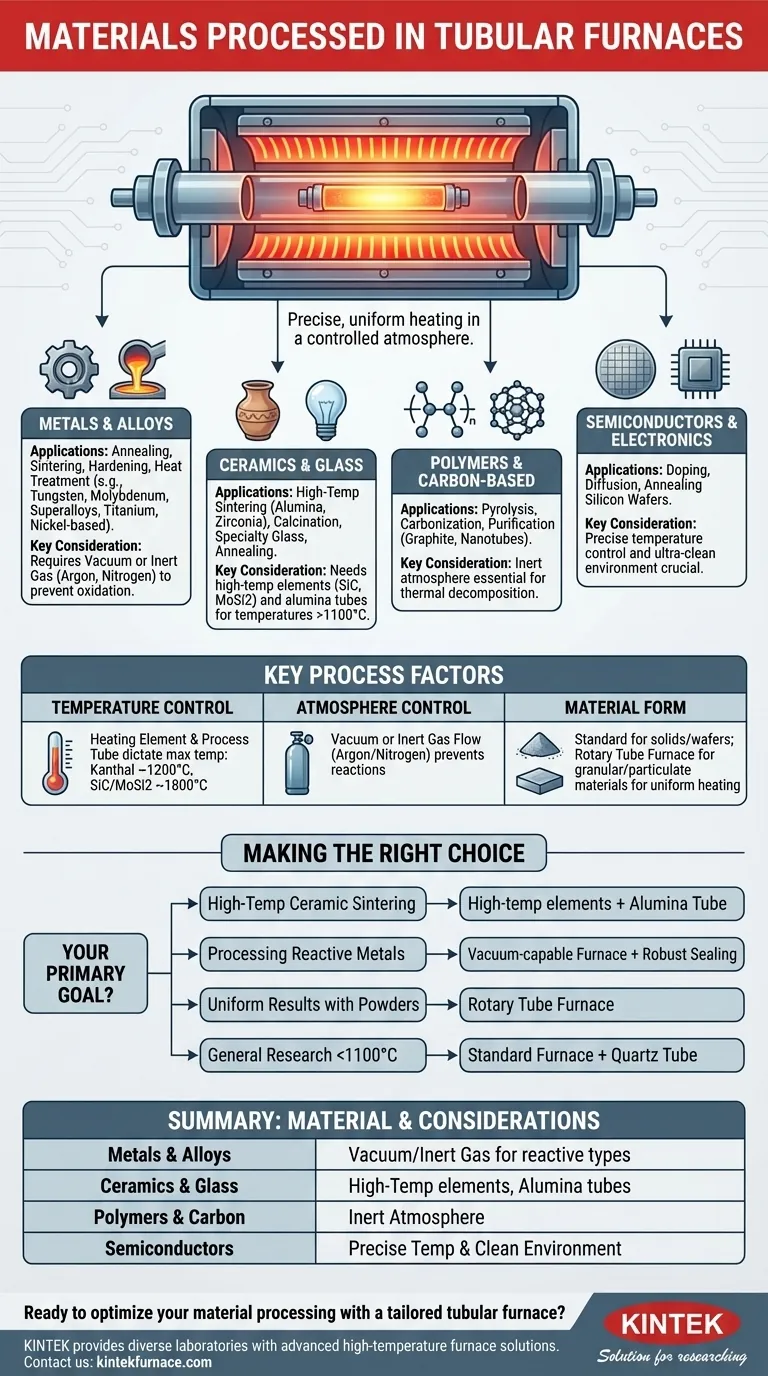

The Fundamental Material Categories

Tubular furnaces are versatile tools, but their primary function is to thermally process materials in a controlled environment. The most common material classes are broken down below.

Metals and Alloys

Metals are frequently processed in tube furnaces for applications like annealing, sintering, hardening, and heat treatment. This includes common metals, refractory metals like tungsten and molybdenum, and advanced superalloys. For reactive metals like titanium or nickel-based alloys, a vacuum or inert gas atmosphere is essential to prevent oxidation.

Ceramics and Glass

These furnaces are ideal for the high-temperature sintering of ceramic powders into dense solids (e.g., alumina, zirconia) and for calcination processes. They are also used for creating specialty glass, annealing glass components to remove internal stresses, and processing ceramic coating materials.

Polymers and Carbon-Based Materials

Specialized processes like pyrolysis (thermal decomposition in an inert atmosphere) and carbonization are performed in tube furnaces. They are also used for the high-temperature purification of materials like graphite and for creating carbon nanotubes and other advanced carbon structures.

Semiconductors and Electronic Materials

The semiconductor industry relies on tube furnaces for critical steps like doping, diffusion, and annealing silicon wafers. The precise temperature control and ultra-clean environment are necessary to achieve the desired electronic properties in these sensitive materials.

It's About the Process, Not Just the Material

Simply knowing a material can be processed is not enough. The success of your work depends on matching the furnace's specific capabilities to your process requirements.

The Role of Temperature

The maximum achievable temperature is dictated by two components: the heating element and the process tube. Elements like Kanthal are common for temperatures up to ~1200°C, while silicon carbide (SiC) or molybdenum disilicide (MoSi2) elements are needed for higher temperatures up to 1800°C.

The Importance of Atmosphere Control

Many materials will react with oxygen at high temperatures, leading to unwanted oxidation. Tube furnaces solve this by enabling processing under:

- A vacuum to remove reactive gases.

- An inert gas flow (like Argon or Nitrogen) to prevent chemical reactions. This is non-negotiable for processing reactive metals, certain ceramics, and for purification processes.

The Form of the Material Matters

The physical form of your material dictates the type of tube furnace you need. While standard furnaces are excellent for solid samples, wafers, or crucibles containing powder, they are inefficient for processing loose powders uniformly.

For granular or particulate materials, a rotary tube furnace is used. It continuously tumbles the material to ensure every particle is exposed to the same temperature, yielding a highly homogenous product.

Understanding the Trade-offs and Limitations

Choosing the right setup involves balancing performance, cost, and chemical compatibility.

Tube Material vs. Temperature

The process tube holding your sample is the most critical consumable. A quartz tube is cost-effective and common for temperatures up to ~1100°C. For higher temperatures, you must use a ceramic tube made of alumina, which can withstand up to 1800°C but is more expensive and brittle.

Chemical Reactivity and Contamination

At very high temperatures, even an "inert" ceramic tube can react with certain sample materials. This can lead to contamination of your sample or degradation of the tube itself. You must always verify the chemical compatibility of your sample material with the process tube at your target temperature.

Unsuitable Material Forms

Standard tube furnaces are not suitable for all processes. Materials that become sticky or melt and flow in an uncontrolled way can damage the process tube. Likewise, trying to heat a large volume of powder in a static tube will result in uneven processing.

Making the Right Choice for Your Goal

Select your furnace configuration based on the primary requirement of your thermal process.

- If your primary focus is high-temperature ceramic sintering: You need a furnace with high-temperature heating elements (SiC or MoSi2) and a high-purity alumina process tube.

- If your primary focus is processing reactive metals: You need a vacuum-capable tube furnace with robust sealing flanges to ensure a pure, oxygen-free environment.

- If your primary focus is achieving uniform results with powders: You need a rotary tube furnace to ensure consistent heating and mixing.

- If your primary focus is general-purpose research below 1100°C: A standard furnace with a quartz tube and basic atmosphere control offers the most versatility and cost-effectiveness.

Ultimately, a tubular furnace is a precision tool defined by its specific components; matching those components to your material and process goal is the key to success.

Summary Table:

| Material Category | Common Applications | Key Considerations |

|---|---|---|

| Metals and Alloys | Annealing, sintering, hardening | Requires vacuum or inert gas for reactive metals |

| Ceramics and Glass | Sintering, calcination, annealing | High-temperature elements and alumina tubes needed |

| Polymers and Carbon-Based | Pyrolysis, carbonization | Inert atmosphere for thermal decomposition |

| Semiconductors and Electronics | Doping, diffusion, annealing | Precise temperature and clean environment essential |

Ready to optimize your material processing with a tailored tubular furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our expertise can enhance your research or production efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab