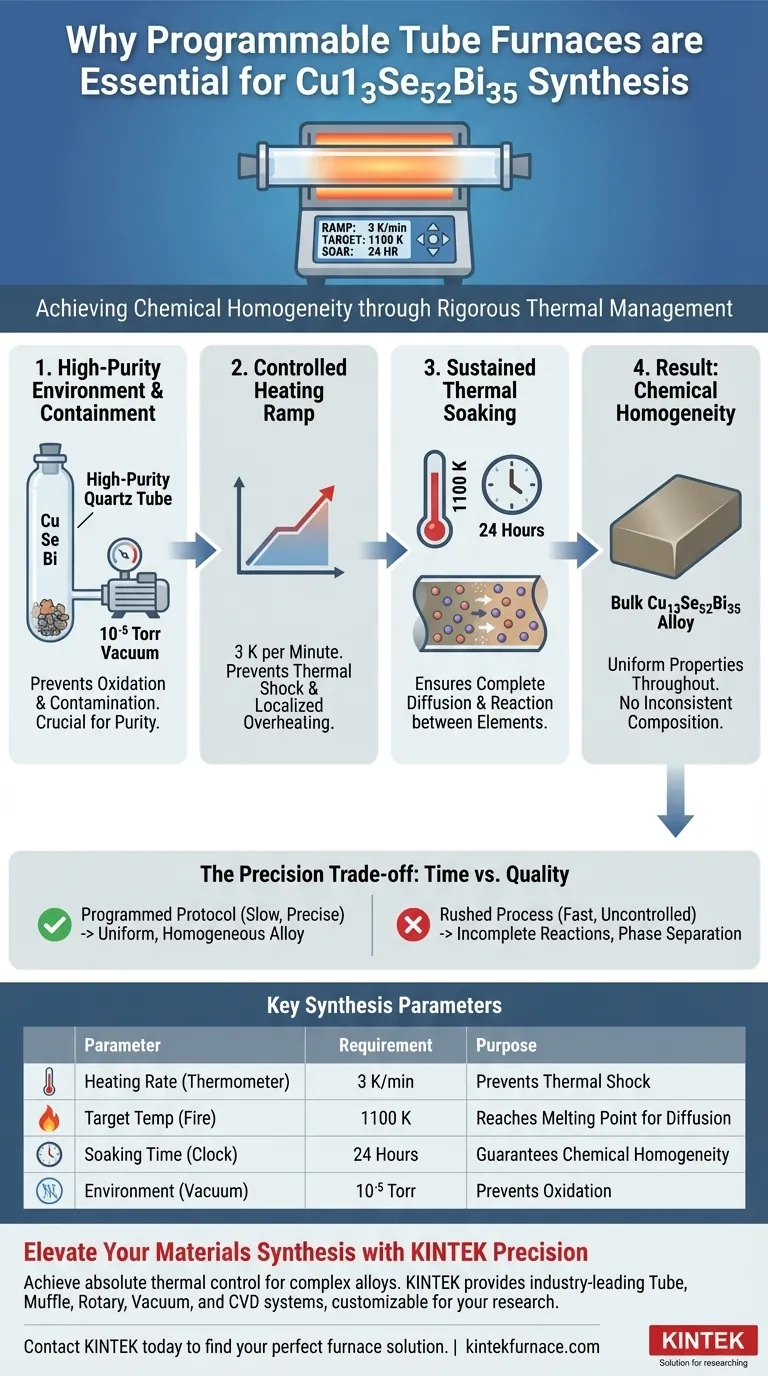

A programmable tube furnace is essential for the synthesis of bulk Cu13Se52Bi35 alloys because it provides the rigorous thermal management required to create a uniform material. Specifically, it executes precise heating rates, such as 3 K per minute, and maintains a stable high temperature of 1100 K for 24 hours to ensure a complete reaction between the elements.

Achieving chemical homogeneity in complex alloys requires more than just high heat; it requires a strictly controlled thermal schedule. The programmable furnace ensures that copper, selenium, and bismuth react thoroughly without the inconsistencies caused by temperature fluctuations.

The Role of Precision Heating

Controlled Temperature Ramps

Standard heating methods often rise to temperature too quickly or unevenly. A programmable tube furnace allows for a specific heating rate, typically set to 3 K per minute for this alloy.

This gradual increase is critical for the melt-quenching process. It allows the raw materials to heat evenly, preventing thermal shock or localized overheating before the reaction temperature is reached.

Sustained Thermal Soaking

Once the target temperature of 1100 K is achieved, the material must be held there for a significant duration. The furnace is programmed to maintain this specific temperature for 24 hours.

This extended "soaking" period is not arbitrary. It provides the necessary time for the atoms of copper, selenium, and bismuth to diffuse and mix completely.

Ensuring Chemical Homogeneity

The primary output of this strict control is chemical homogeneity. Without the stable environment provided by the programmable furnace, the resulting alloy body would likely suffer from inconsistent composition.

By eliminating temperature spikes or drops, the furnace ensures that the constituent elements react thoroughly. This results in a bulk alloy with uniform properties throughout its structure.

The Importance of the Furnace Environment

Containment and Purity

While the furnace controls the heat, the physical synthesis occurs inside high-purity quartz tubes. These tubes serve as the container for the raw elemental materials within the furnace bore.

Preventing Oxidation

To maintain purity, the environment within the quartz tubes is manipulated before heating begins. Using vacuum sealing equipment, the internal pressure is reduced to 10^-5 Torr.

This high-vacuum environment is crucial during the high-temperature melting process managed by the furnace. It effectively prevents the raw materials from oxidizing or absorbing atmospheric impurities, which would degrade the alloy's performance.

Understanding the Trade-offs

Time vs. Quality

The primary trade-off in using a programmable tube furnace for this synthesis is the process time. A 3 K/minute ramp coupled with a 24-hour hold is a slow, energy-intensive process.

The Risk of Shortcuts

Attempting to accelerate this process using rapid heating or shorter soak times carries significant risk. Rushing the synthesis often leads to incomplete reactions or phase separation, where the elements fail to integrate into a single, homogeneous alloy.

Making the Right Choice for Your Goal

To successfully synthesize Cu13Se52Bi35, your equipment choice dictates the quality of your output.

- If your primary focus is material uniformity: You must strictly adhere to the programmed heating rate of 3 K/min and the 24-hour dwelling time to guarantee chemical homogeneity.

- If your primary focus is purity: You must ensure the quartz tube is sealed at 10^-5 Torr prior to inserting it into the furnace to prevent oxidation during the 1100 K melt.

Precision in thermal management is the defining factor between a failed sample and a usable semiconductor alloy.

Summary Table:

| Parameter | Requirement | Purpose in Synthesis |

|---|---|---|

| Heating Rate | 3 K per minute | Prevents thermal shock and ensures even heating |

| Target Temp | 1100 K | Reaches the melting point required for diffusion |

| Soaking Time | 24 Hours | Guarantees chemical homogeneity and thorough reaction |

| Environment | 10^-5 Torr Vacuum | Prevents oxidation and atmospheric contamination |

Elevate Your Materials Synthesis with KINTEK Precision

Achieving chemical homogeneity in complex alloys like Cu13Se52Bi35 requires more than just high heat—it demands absolute thermal control. KINTEK provides industry-leading Tube, Muffle, Rotary, Vacuum, and CVD systems, all engineered to deliver the precise heating ramps and stable soaking periods your research requires.

Backed by expert R&D and advanced manufacturing, our high-temperature lab furnaces are fully customizable to meet your unique alloy synthesis needs. Don't compromise on material purity or uniformity. Contact KINTEK today to find your perfect furnace solution.

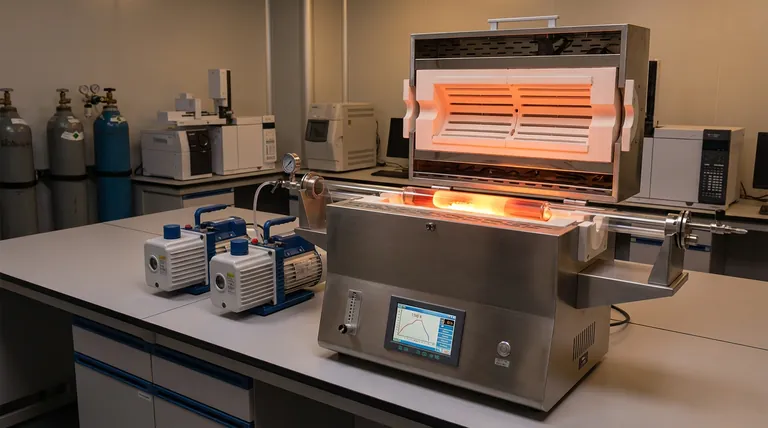

Visual Guide

References

- Abduelwhab B. Alwany, Abdulnasser Abdulrahman Alfaqeer. Effect of annealing temperature on the structural and optical properties of vacuum evaporated Cu13Se52Bi35 thin films. DOI: 10.15251/cl.2024.211.99

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of using a high-temperature tube furnace for the post-deposition annealing of ITO? Optimize Film Performance

- What heating element is used in a multi station vacuum tube furnace and what types of furnace tubes can be used? Optimize Your High-Temp Processes

- How does a horizontal tube furnace work? Master Precise Thermal Processing for Your Lab

- Why is a tube furnace with precise temperature control necessary for synthesizing high-quality monolayer MoS2?

- How does a multi-zone furnace work? Achieve Personalized Comfort and Energy Efficiency

- What roles do sliding rails and lifting handles play in split tube furnaces? Enhance Safety & Precision in CVD Systems

- How does the vacuum environment in a tube furnace benefit material processing? Achieve Purity and Performance

- What is the significance of the slow cooling process in a high-temperature tube furnace? Master TMD Synthesis Quality