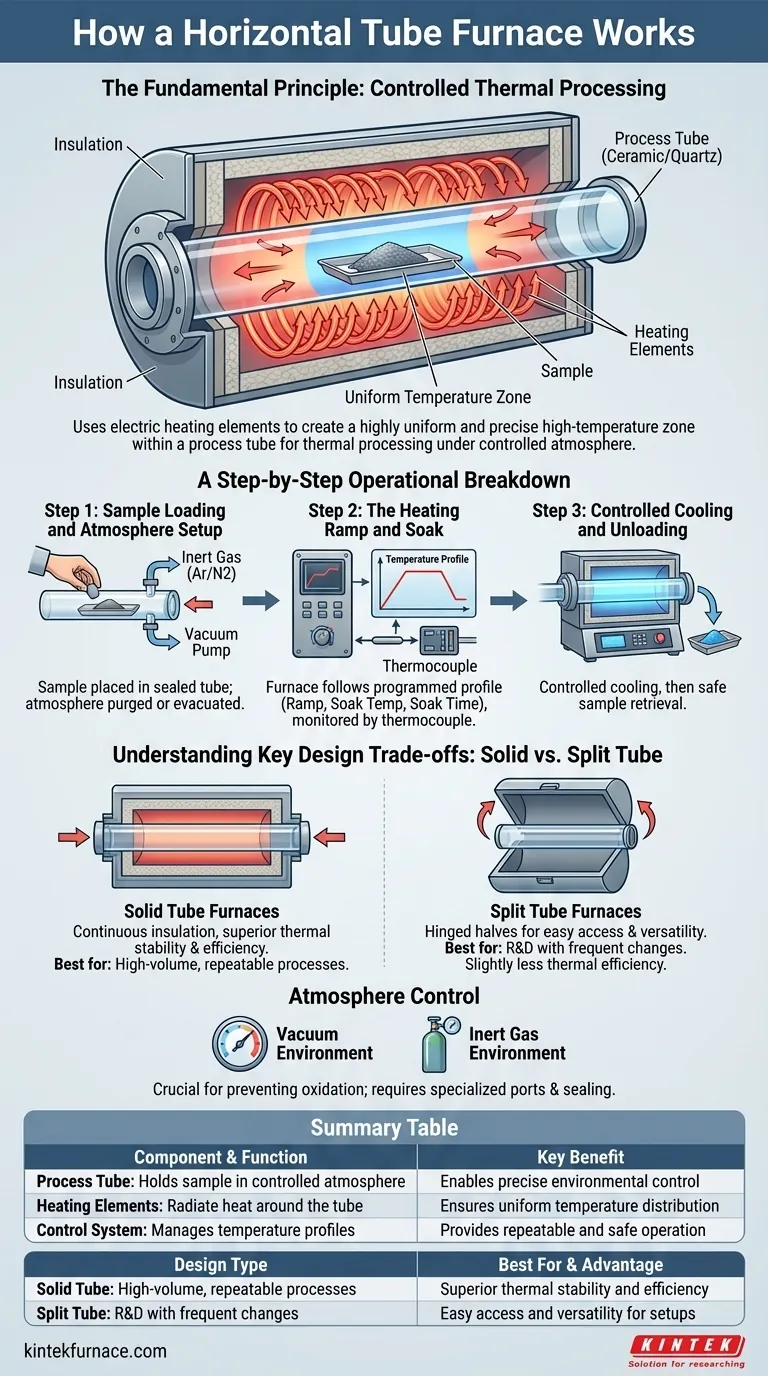

At its core, a horizontal tube furnace works by using electric heating elements to create a highly uniform and precisely controlled high-temperature zone within a horizontal tube. This allows for the thermal processing of materials, often in a specific atmosphere like a vacuum or inert gas, for applications ranging from materials synthesis to quality control testing.

The purpose of a horizontal tube furnace isn't just to generate heat; it's to create an exceptionally stable and uniform thermal environment. Understanding this core function is key to choosing the right design—primarily solid or split tube—for your specific operational needs.

The Fundamental Principle: Controlled Thermal Processing

A horizontal tube furnace is an electric heating device designed for one primary purpose: to apply a precise thermal profile to a sample. The entire design is optimized to achieve this with high repeatability and control.

The Role of the Process Tube

The sample material is not placed directly into the furnace chamber. Instead, it is loaded into a separate process tube, typically made of ceramic, quartz, or a specialized metal alloy, which is then inserted into the furnace.

This tube acts as the micro-environment for your sample, allowing you to control the atmosphere inside it independently of the air outside.

The Function of the Heating Elements

The furnace chamber contains electric heating elements that surround the process tube. When activated, these elements radiate thermal energy, heating the chamber and, in turn, the process tube and the sample within it.

This indirect heating method is crucial for ensuring the temperature is applied evenly from all sides.

Achieving Temperature Uniformity

The horizontal orientation is deliberate. It allows for the creation of a long, stable, and uniform temperature zone in the center of the tube. High-quality furnace designs minimize temperature drop-off at the ends to maximize the usable processing area for the sample.

A Step-by-Step Operational Breakdown

The operation of a tube furnace is a methodical process designed for precision and safety. Each stage is carefully managed by the furnace's control system.

Step 1: Sample Loading and Atmosphere Setup

First, the sample is placed inside the process tube. The tube is then sealed, and if required, it is purged with an inert gas (like argon or nitrogen) or evacuated with a vacuum pump to create a specific processing atmosphere.

Step 2: The Heating Ramp and Soak

The furnace is programmed with a desired temperature profile. This includes the "ramp rate" (how quickly the temperature rises), the "soak temperature" (the target processing temperature), and the "soak time" (how long it stays at that temperature).

The control system activates the heating elements and uses a thermocouple to monitor the temperature, precisely managing power to follow the programmed profile.

Step 3: Controlled Cooling and Unloading

After the soak is complete, the furnace begins a controlled cooling phase. Once the furnace has cooled to a safe temperature, the process tube can be removed, and the processed sample can be retrieved.

Understanding the Key Design Trade-offs

Horizontal tube furnaces are generally classified into two main types: solid and split tube. The choice between them is the most significant decision you will make, as it directly impacts your workflow.

Solid Tube Furnaces: Simplicity and Stability

A solid tube furnace features a continuous, one-piece insulation chamber. The process tube is inserted from the ends.

This design offers superior thermal insulation and temperature uniformity because there are no seams or breaks in the heating chamber. It is ideal for established, repeatable processes where the setup does not change frequently.

Split Tube Furnaces: Access and Versatility

A split tube furnace, also known as a hinged furnace, is built in two semi-cylindrical halves connected by a hinge. This allows the chamber to be opened like a clamshell.

This design provides much easier access to the process tube, making it faster to place or remove tubes, especially those with complex attachments. It is favored in research and development environments where frequent sample changes and setup modifications are common. The trade-off is slightly less thermal efficiency compared to a solid design.

The Importance of Atmosphere Control

The ability to process a sample under a specific atmosphere is a critical feature. For applications like annealing or sintering sensitive materials, preventing oxidation is non-negotiable. Ensure the furnace you consider has the necessary ports and sealing flanges to support a vacuum or inert gas environment if your process requires it.

Making the Right Choice for Your Application

Selecting the correct furnace configuration depends entirely on your primary goal. The design that excels in a high-volume production lab may be inefficient for exploratory research.

- If your primary focus is repeatable, high-volume processing: A solid tube furnace offers the best thermal stability and efficiency for standardized workflows.

- If your primary focus is research and development with frequent sample changes: A split tube furnace provides invaluable convenience and significantly reduces turnaround time between experiments.

- If your primary focus is material purity and reaction control: Prioritize a system with robust atmosphere control capabilities, including high-quality seals and ports for vacuum and gas lines.

Ultimately, choosing the right horizontal tube furnace means matching the instrument's design to the demands of your specific thermal processing task.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Process Tube | Holds sample in controlled atmosphere | Enables precise environmental control |

| Heating Elements | Radiate heat around the tube | Ensures uniform temperature distribution |

| Control System | Manages temperature profiles | Provides repeatable and safe operation |

| Design Type | Best For | Advantage |

| Solid Tube | High-volume, repeatable processes | Superior thermal stability and efficiency |

| Split Tube | R&D with frequent changes | Easy access and versatility for setups |

Ready to enhance your lab's thermal processing with a custom horizontal tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our furnaces can boost your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency