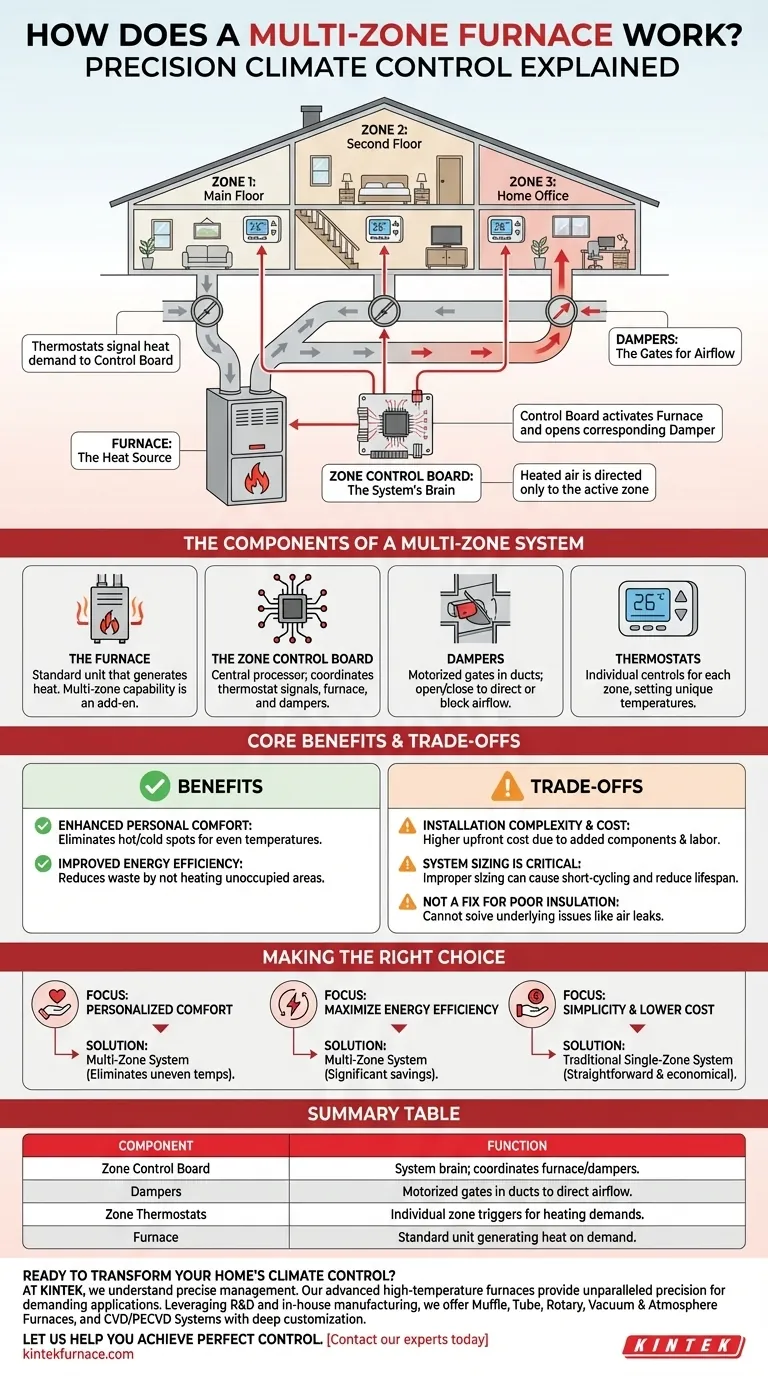

At its core, a multi-zone furnace system works by dividing a home’s ductwork into distinct areas, or "zones," that can be heated independently. Instead of a single thermostat controlling the entire house, each zone has its own thermostat. When a zone calls for heat, a central control panel instructs the furnace to turn on and opens a motorized gate, called a damper, in the ductwork to direct warm air only to that specific zone.

A multi-zone system transforms a standard, brute-force furnace into a precise climate control network. It stops treating your home as a single entity and instead directs conditioned air only to the areas that actually need it, when they need it.

The Components of a Multi-Zone System

A standard furnace does not work as a multi-zone system on its own. It requires a set of specific components working in concert to create and manage the different climate areas within your home.

The Furnace: The Source of Heat

The furnace itself is often a standard, single-stage or multi-stage unit. Its job remains the same: to generate heat. The "multi-zone" capability is an add-on system that controls how the furnace's output is distributed.

The Zone Control Board: The System's Brain

This central processor is the heart of the system. It receives signals from each thermostat in every zone.

Based on these signals, it tells the furnace to turn on or off and commands the specific dampers to open or close, coordinating the entire operation.

Dampers: The Gates for Airflow

Dampers are the physical mechanism of control. These are motorized plates installed inside your ducts. Think of them as automated gates.

When a zone needs heat, its corresponding damper opens; when the temperature is satisfied, it closes. This prevents heated air from entering zones that are already comfortable.

Thermostats: The Triggers for Each Zone

Each designated zone requires its own thermostat. This allows you to set a unique temperature for the bedrooms, the main floor, or a home office, giving you granular control over your environment.

The Core Benefits of Zoned Climate Control

Transitioning from a single-zone to a multi-zone system is driven by two primary goals: improving comfort and increasing efficiency.

Enhanced Personal Comfort

The most common problem solved by zoning is uneven temperatures. A multi-zone system eliminates hot and cold spots, such as a second floor that's always warmer than the first, by treating them as separate environments.

Improved Energy Efficiency

By not heating or cooling unoccupied rooms, you significantly reduce wasted energy. A zoned system allows you to lower the temperature in guest rooms or storage areas while keeping your living spaces comfortable, directly lowering your utility bills.

Understanding the Trade-offs and Considerations

While powerful, a multi-zone system is not a universal solution and introduces its own set of complexities that require careful planning.

Installation Complexity and Cost

Retrofitting a home for a multi-zone system is a complex job that requires professional installation. The added components—the control board, dampers, and thermostats—and the labor involved mean a significantly higher upfront cost compared to a traditional single-zone setup.

System Sizing is Critical

A crucial consideration is ensuring the furnace and ductwork can function properly when only the smallest zone is calling for heat. An improperly designed system can lead to excessive air pressure and cause the furnace to short-cycle (turn on and off too frequently), which reduces efficiency and lifespan.

Not a Fix for Poor Insulation

A multi-zone system can manage temperature differences, but it cannot solve underlying problems like poor insulation, air leaks, or inefficient windows. It is a tool for control, not a substitute for a well-sealed building envelope.

Making the Right Choice for Your Home

The decision to implement a multi-zone system depends entirely on your specific goals for your home's climate.

- If your primary focus is personalized comfort: A multi-zone system is the definitive solution for eliminating hot/cold spots and giving family members individual control.

- If your primary focus is maximizing energy efficiency: Zoning provides significant savings by allowing you to avoid heating or cooling unoccupied areas of your home.

- If your primary focus is simplicity and lower upfront cost: A traditional single-zone system remains the most straightforward and economical choice, provided your home heats and cools relatively evenly.

Ultimately, understanding this principle of targeted airflow is the key to determining whether a zoned approach is the right investment for you.

Summary Table:

| Component | Function |

|---|---|

| Zone Control Board | The system's brain; coordinates furnace and dampers based on thermostat signals. |

| Dampers | Motorized gates in ducts that open/close to direct airflow to specific zones. |

| Zone Thermostats | Individual thermostats for each zone that trigger heating demands. |

| Furnace | Standard heating unit that generates heat on demand from the control board. |

Ready to transform your home's climate control?

At KINTEK, we understand that precise temperature management is crucial, whether for your home or your laboratory. Just as a multi-zone furnace delivers targeted comfort, our advanced high-temperature furnaces provide unparalleled precision for your most demanding applications.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you achieve perfect control. Contact our experts today to discuss your specific needs and discover how our solutions can bring efficiency and precision to your work.

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing