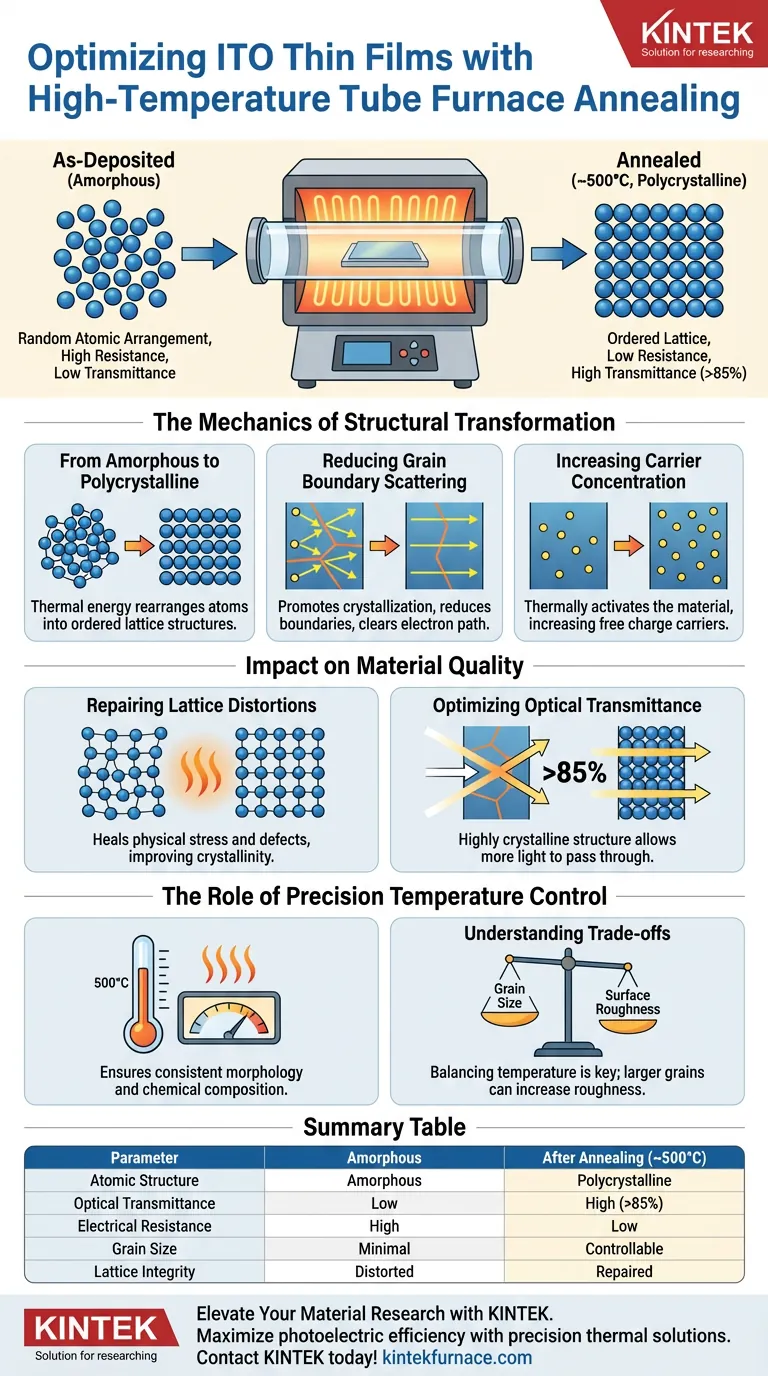

The primary purpose of using a high-temperature tube furnace for the post-deposition annealing of Indium Tin Oxide (ITO) thin films is to fundamentally alter the material's atomic structure to optimize its photoelectric performance.

By processing the film at temperatures typically around 500°C, the furnace facilitates a critical phase transition from an amorphous, disordered state to a highly ordered polycrystalline structure. This structural reorganization is the key mechanism that lowers electrical resistivity and increases visible light transmittance to over 85%.

Core Takeaway The tube furnace acts as a structural corrective tool, using thermal energy to repair atomic disorder introduced during deposition. By converting the ITO film into a polycrystalline state, you simultaneously minimize barriers to electron flow and maximize optical clarity, making the material viable for high-performance electronic applications.

The Mechanics of Structural Transformation

From Amorphous to Polycrystalline

As-deposited ITO films often possess an amorphous structure, where atoms are arranged randomly. This lack of order impedes electron movement and degrades optical quality.

Annealing provides the necessary thermal activation energy to rearrange these atoms. This shifts the material into a polycrystalline state, where atoms align into ordered lattice structures.

Reducing Grain Boundary Scattering

In a disordered state, electrons frequently collide with imperfections, a phenomenon known as grain boundary scattering. This scattering significantly increases electrical resistance.

By promoting crystallization and growing larger grains, the annealing process reduces the density of these boundaries. This clears the path for electrons, resulting in a conductive film with much lower resistivity.

Increasing Carrier Concentration

The thermal environment of the tube furnace does more than just align atoms; it activates the material electronically.

The process increases the carrier concentration within the film. A higher density of free charge carriers directly correlates to improved electrical conductivity without compromising the film's transparency.

Impact on Material Quality

Repairing Lattice Distortions

Deposition processes, such as sputtering, often introduce physical stress and defects into the film's crystal lattice.

The controlled thermal field of a tube furnace promotes atomic thermal diffusion, which effectively repairs these lattice distortions. This "healing" process improves the overall crystallinity and stability of the film.

Optimizing Optical Transmittance

A highly crystalline structure interacts with light more efficiently than a disordered one.

By eliminating internal defects and optimizing the lattice, the film allows more light to pass through. Post-annealing, ITO films typically achieve a visible light transmittance of over 85%, a benchmark requirement for most optoelectronic devices.

The Role of Precision Temperature Control

Determining Grain Size

Temperature acts as the primary dial for controlling the morphology of the film.

While 500°C is standard for crystallization, higher temperatures can drive further grain growth. For example, in specific high-temperature scenarios, increasing heat can expand grain sizes significantly (e.g., from ~35 nm to ~100 nm), though this depends heavily on the specific deposition goals.

Ensuring Uniformity

A tube furnace is designed to provide a specific, stable temperature field.

This uniformity is critical because even minor fluctuations can lead to uneven crystallization. Precise control ensures the film achieves a consistent morphology and chemical composition across the entire substrate.

Understanding the Trade-offs

Balancing Temperature and Substrate Limits

While higher temperatures generally improve crystallinity, they must be balanced against the thermal tolerance of your substrate.

Pushing temperatures too high (e.g., toward 1000°C or 1200°C, which are used for specific growth kinetics rather than standard film annealing) risks damaging the substrate or altering the film's stoichiometry unfavorably.

Grain Size vs. Surface Roughness

Aggressive annealing to maximize grain size can have a side effect: increased surface roughness.

While large grains improve conductivity, a rough surface can be detrimental if the ITO film is meant to serve as a base for subsequent, delicate layers in a device stack.

Making the Right Choice for Your Goal

To maximize the utility of your ITO films, tailor your annealing strategy to your specific performance metrics:

- If your primary focus is Conductivity and Transparency: Target a standard annealing temperature around 500°C to ensure the amorphous-to-polycrystalline transition occurs, achieving low resistivity and >85% transmittance.

- If your primary focus is Grain Size Engineering: Utilize high-precision temperature controllers to explore higher thermal ranges, understanding that increasing temperature drives grain growth (e.g., up to ~100 nm) but requires careful management of surface morphology.

Success in ITO annealing relies on providing just enough thermal energy to order the lattice without degrading the physical integrity of the film or substrate.

Summary Table:

| Parameter | Before Annealing (As-deposited) | After Annealing (~500°C) |

|---|---|---|

| Atomic Structure | Amorphous / Disordered | Polycrystalline / Ordered |

| Optical Transmittance | Low / Variable | High (>85%) |

| Electrical Resistance | High (Grain scattering) | Low (Improved mobility) |

| Grain Size | Minimal / None | Controllable (up to 100nm+) |

| Lattice Integrity | High distortion/stress | Repaired / Stabilized |

Elevate Your Material Research with KINTEK

Maximize the photoelectric efficiency of your ITO thin films with precision thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for your specific laboratory needs. Whether you require advanced grain size engineering or uniform phase transitions, our customizable high-temperature furnaces deliver the stability your research demands.

Ready to optimize your annealing process? Contact KINTEK today to discuss your unique requirements!

Visual Guide

References

- Hessa I. Alabdan, Tapas K. Mallick. Monolithic Use of Inert Gas for Highly Transparent and Conductive Indium Tin Oxide Thin Films. DOI: 10.3390/nano14070565

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the function of a vertical alumina tube reactor in black liquor char gasification? Precision Kinetic Analysis

- How does a dual-temperature zone tube furnace contribute to the carbonization of biomass? Precise Material Engineering

- What is the uniform length of a tube furnace and what factors affect it? Maximize Your Lab's Thermal Precision

- What are the differences between solid and split tube furnaces? Choose the Right Furnace for Your Lab

- Why must catalysts undergo reduction in a tube furnace? Master Your Furfural Hydrogenation Preparation

- What is the role of mixing precursor with sulfur powder? Master Sulfidation in Tube Furnaces for Fe7S8@CT-NS

- What are the primary benefits of using a split tube furnace? Enhance Lab Efficiency with Unmatched Flexibility

- How does a high-temperature tube furnace contribute to the pore regulation of carbon nanofibers? Precision Engineering