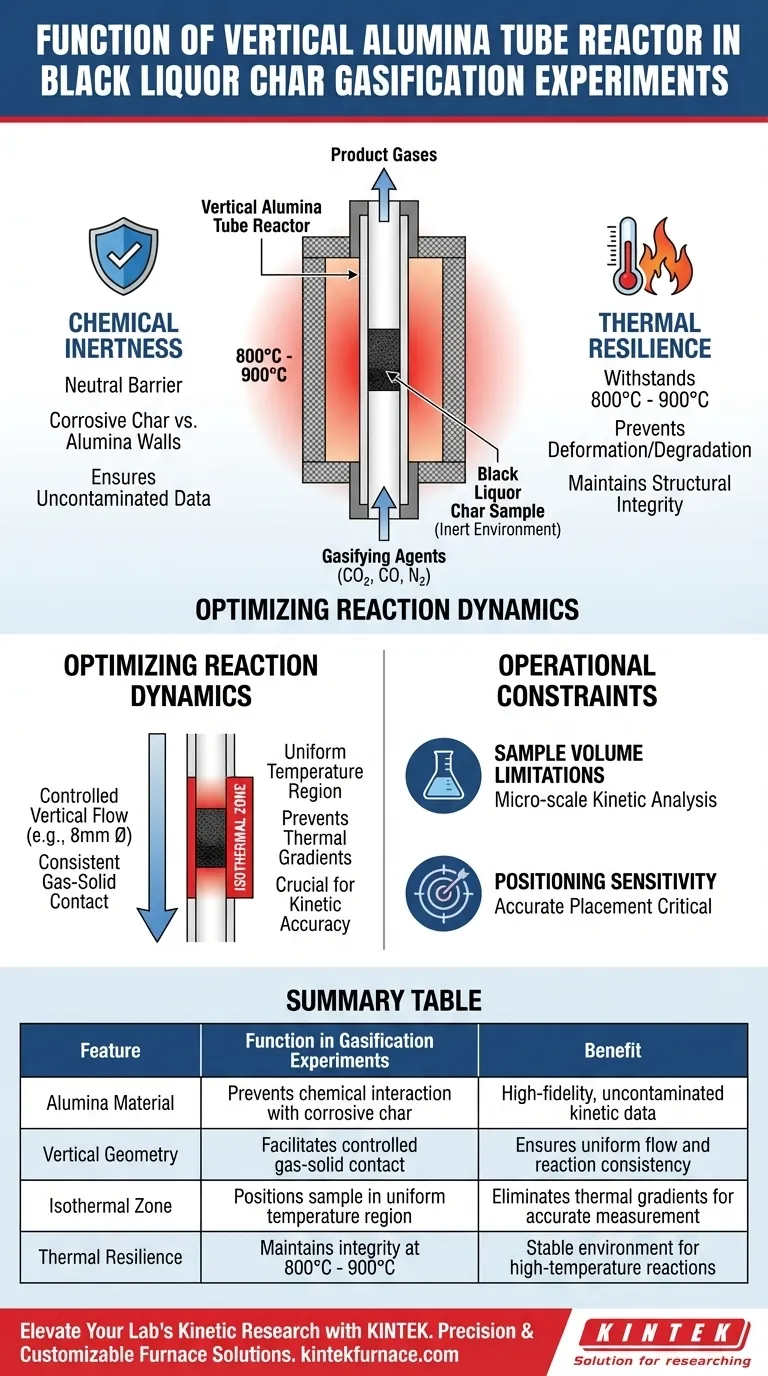

In black liquor char gasification experiments, the vertical alumina tube reactor functions as the primary containment vessel designed to isolate specific chemical reaction kinetics. It provides a chemically inert environment that withstands temperatures between 800°C and 900°C, ensuring that corrosive black liquor char interacts only with the gasifying agents and not the reactor walls. This setup is essential for obtaining accurate, uncontaminated data regarding carbon conversion rates.

By combining high-temperature stability with specific vertical geometry, this reactor design eliminates external variables, allowing researchers to measure the intrinsic kinetic characteristics of the fuel source with high precision.

Engineering High-Fidelity Data

To understand why this specific reactor type is used, one must look at the material requirements of processing black liquor char.

Chemical Inertness

The primary role of the alumina material is to act as a neutral barrier. Black liquor char is highly corrosive, and accurate kinetic measurement requires that the reactor walls do not participate in the chemical process.

Alumina ensures that the carbon conversion is driven solely by the interaction between the char and the gasifying agents.

Thermal Resilience

Gasification requires intense heat to initiate and sustain reactions. The reactor is specifically engineered to maintain structural integrity within the critical 800°C to 900°C operating window.

This thermal resistance prevents physical deformation or material degradation that could skew experimental results.

Optimizing Reaction Dynamics

Beyond material properties, the physical geometry of the tube plays a crucial role in how the experiment is conducted.

Controlled Vertical Flow

The reactor typically features a narrow design, often around 300mm in length with an 8mm diameter. This geometry forces reaction gases—such as CO2, CO, and N2—to flow vertically through the center of the tube.

This ensures the gas passes directly through the sample area, facilitating effective and consistent gas-solid contact.

The Isothermal Zone

The vertical arrangement is not arbitrary; it is designed to position the sample within a specific "isothermal zone" of the furnace.

By keeping the sample in this zone, researchers ensure that the temperature remains uniform throughout the reaction, preventing thermal gradients that could distort kinetic data.

Understanding the Operational Constraints

While the vertical alumina tube is ideal for kinetic studies, it imposes specific operational limitations that must be managed.

Sample Volume Limitations

The narrow diameter (e.g., 8mm) restricts the volume of char that can be processed in a single run. This design is optimized for micro-scale kinetic analysis rather than bulk processing or throughput.

Positioning Sensitivity

Because the accuracy of the data relies on the "isothermal zone," the physical placement of the sample within the tube is critical. Slight misalignments can move the sample out of the uniform temperature region, compromising the validity of the reaction data.

Making the Right Choice for Your Experiment

When designing a gasification experiment, the choice of reactor defines the quality of your data.

- If your primary focus is material compatibility: Rely on alumina construction to prevent corrosive interactions between the black liquor char and the vessel walls.

- If your primary focus is kinetic accuracy: Utilize the vertical tube geometry to ensure uniform gas flow and precise placement within the furnace's isothermal zone.

Success in these experiments ultimately depends on isolating the variable you wish to measure, and the vertical alumina tube is the standard tool for achieving that isolation.

Summary Table:

| Feature | Function in Gasification Experiments | Benefit |

|---|---|---|

| Alumina Material | Prevents chemical interaction with corrosive char | High-fidelity, uncontaminated kinetic data |

| Vertical Geometry | Facilitates controlled gas-solid contact | Ensures uniform flow and reaction consistency |

| Isothermal Zone | Positions sample in uniform temperature region | Eliminates thermal gradients for accurate measurement |

| Thermal Resilience | Maintains integrity at 800°C - 900°C | Stable environment for high-temperature reactions |

Elevate Your Lab’s Kinetic Research with KINTEK

Precision in gasification experiments starts with the right equipment. KINTEK provides high-performance Tube, Muffle, and Vacuum systems, backed by expert R&D and manufacturing. Our vertical alumina reactors are customizable to meet your unique experimental needs, ensuring your research achieves the highest accuracy and reproducibility.

Ready to optimize your high-temperature processes? Contact KINTEK today to find the perfect customizable furnace solution for your laboratory.

Visual Guide

References

- Fernando Leo Bueno - CO₂ Gasification of Black Liquor Char under isothermal and dynamic conditions. DOI: 10.26754/jji-i3a.202512148

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is an atmosphere-protected tube furnace preferred for LMTOF1244? Ensuring Precise Chemical Stoichiometry

- What is the role of a vacuum tube furnace during the final thermal treatment stage of Fe3O4@CSAC catalysts?

- What are the advantages of using a high-temperature tube furnace for rGO sensor fabrication? Precision & Performance

- Why is a high-temperature tube furnace used for PCN exfoliation? Unlock Superior 2D Nanosheet Catalysis

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the essential functional requirements for a tube furnace used in the biomass activated carbon activation process?

- What role does a laboratory tube furnace play in the carbonization process of moxa floss? Expert Guide to Biomass Synthesis

- How does a vacuum tube furnace contribute to the annealing of FePC amorphous alloys? Precision Microstructural Control