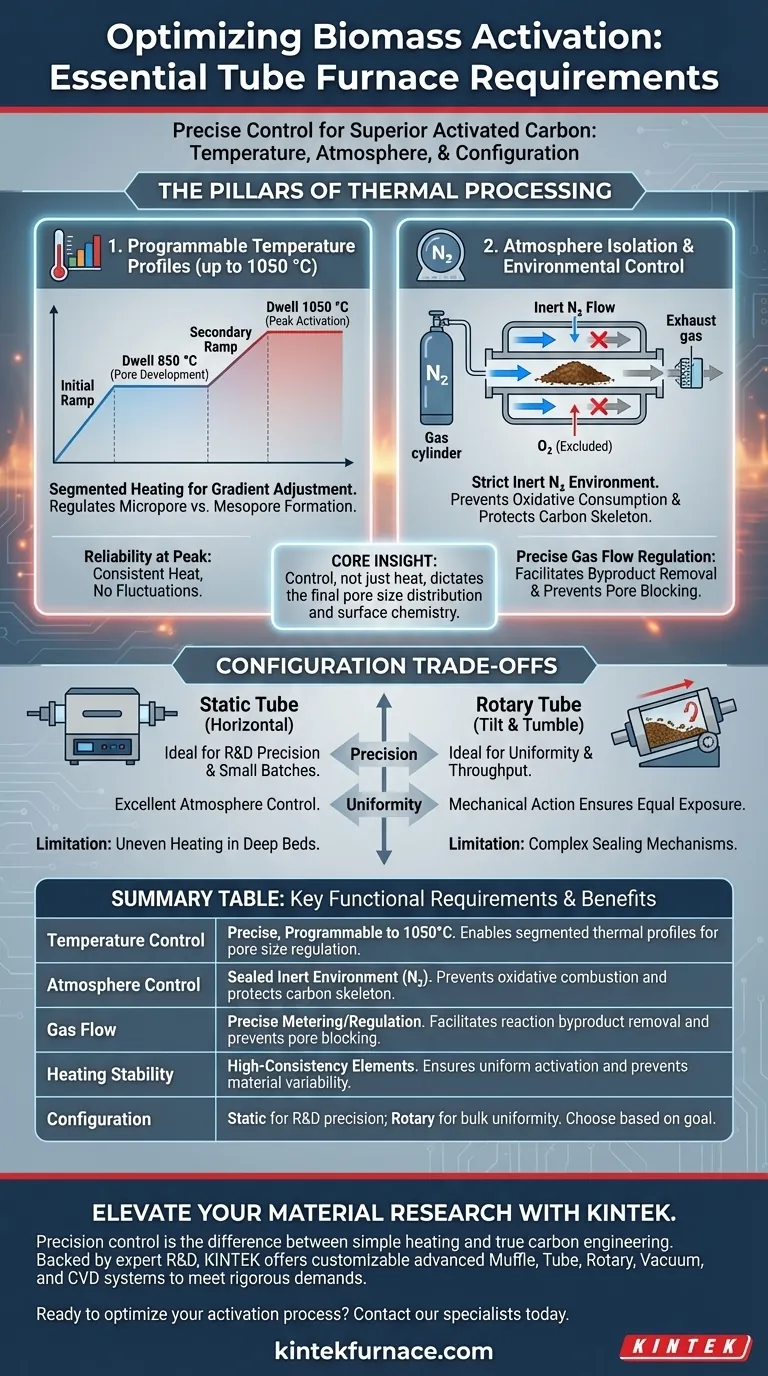

The essential functional requirements for a tube furnace used in biomass activated carbon activation are precise, programmable temperature control and a highly reliable atmosphere isolation system. To effectively process biomass, the unit must be capable of executing segmented thermal profiles reaching up to 1050 °C while maintaining a strictly inert Nitrogen (N2) environment to prevent material oxidation.

Core Insight: The quality of activated carbon is not determined merely by heat, but by control. The furnace's ability to transition smoothly between specific temperature plateaus under a stable inert gas flow is what dictates the final pore size distribution and surface chemistry of the material.

The Pillars of Thermal Processing

Programmable Temperature Profiles

The activation process is rarely linear; it requires a specific "recipe" of heating rates and dwell times.

Segmented heating is critical. The furnace must allow you to program distinct stages, such as an initial rise to 850 °C followed by a secondary ramp to 1050 °C.

This segmentation allows for gradient adjustment. By controlling how long the biomass stays at specific temperatures, you directly regulate the development of micropores versus mesopores.

High-Temperature Capability

For deep activation, the furnace must comfortably sustain temperatures up to 1050 °C.

While initial carbonization may occur at lower temperatures, the creation of a high-quality pore structure requires significant thermal energy.

Reliability at peak temperature is key. The heating elements must deliver consistent heat at these upper limits without fluctuation, as instability can lead to uneven activation.

Atmosphere and Environmental Control

Inert Gas Isolation

The single biggest risk in this process is the oxidative consumption of your biomass. If oxygen enters the chamber at 850 °C, the material will simply burn away.

A sealed Nitrogen (N2) system is mandatory. The furnace requires a continuous flow of inert gas to displace oxygen and create the reduction environment necessary for activation.

This environment protects the carbon skeleton. It ensures that mass loss is due to the targeted removal of volatiles and pore creation, not uncontrolled combustion.

Gas Flow Regulation

The system must allow for the precise metering of gas flow rates.

Continuous flow facilitates reactions. Whether using Nitrogen or introducing reducing gases like hydrogen mixtures, the flow transports reaction byproducts away from the material.

Proper flow control prevents the re-deposition of tars or volatiles onto the activated carbon surface, which would otherwise block the newly formed pores.

Understanding the Trade-offs

Static vs. Rotary Configurations

While a standard horizontal tube furnace offers excellent atmosphere control, it has limitations regarding material uniformity.

Static furnaces are ideal for precise R&D or small batches where surface chemistry study is the goal. However, they may suffer from uneven heating if the powder bed is too deep.

Rotary tube furnaces introduce mechanical complexity (rotation speed, tilt angle) but solve the uniformity problem. By tumbling the biomass, they ensure every particle receives equal exposure to heat and the activating agent (such as KOH).

Throughput vs. Precision

Choosing a continuous rotary system increases throughput but requires more complex sealing mechanisms to maintain the inert atmosphere.

Batch processing (standard tube) generally offers a tighter seal and more rigorously controlled environment, making it superior for determining exact specific surface area parameters during the research phase.

Making the Right Choice for Your Goal

The "perfect" furnace depends heavily on whether you are characterizing a new material or scaling up production.

- If your primary focus is Research & Development: Prioritize a standard horizontal tube furnace with advanced multi-segment programming to precisely determine optimal activation temperatures and pore structures.

- If your primary focus is Uniformity and Throughput: Select a rotary tube tilt furnace to ensure consistent mixing and heat exposure across larger volumes of biomass.

- If your primary focus is Chemical Activation: Ensure the furnace tube material is resistant to corrosive agents like Potassium Hydroxide (KOH) and can support high-flow inert gas to manage volatile byproducts.

Ultimately, the furnace is a precision instrument for sculpting carbon; select the unit that offers the tightest control over the environment, not just the highest temperature.

Summary Table:

| Feature | Requirement for Biomass Activation | Benefit/Impact |

|---|---|---|

| Temperature Control | Precise, Programmable (up to 1050°C) | Enables segmented thermal profiles for pore size regulation. |

| Atmosphere Control | Sealed Inert Environment (N2) | Prevents oxidative combustion and protects carbon skeleton. |

| Gas Flow | Precise Metering/Regulation | Facilitates reaction byproduct removal and prevents pore blocking. |

| Heating Stability | High-Consistency Elements | Ensures uniform activation and prevents material variability. |

| Configuration Choice | Static vs. Rotary | Static for R&D precision; Rotary for bulk material uniformity. |

Elevate Your Material Research with KINTEK

Precision control is the difference between simple heating and true carbon engineering. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of biomass activation and high-temp lab processes.

Whether you need superior atmosphere isolation for research or high-throughput rotary solutions for production, our engineers provide the technical edge your laboratory requires.

Ready to optimize your activation process? Contact our specialists today to find your custom furnace solution.

Visual Guide

References

- Shengfei Zhou, Markus J. Buehler. Enhanced Electrochemical Properties of Biobased Activated Carbon for Supercapacitors. DOI: 10.1002/adem.202401964

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What types of materials can be processed in a vacuum tube furnace? Unlock High-Purity Processing for Metals, Ceramics, and More

- What role does a high-temperature tube furnace play in the final thermal treatment of Na3(VO1-x)2(PO4)2F1+2x?

- What is the purpose of a stepper motor equipped with a 100:1 reducer in a tube furnace? Achieve Precision Control

- How does a high vacuum tube furnace ensure accuracy in Sn-Ag-Cu-Mn-Er solder experiments? Optimize Wetting Analysis

- What are the advantages of using a vertical tube furnace? Achieve Superior Purity and Thermal Uniformity

- What is the purpose of using a high-temperature tube furnace during FePt annealing? Achieve the L1₀ Magnetic Phase

- What role does a horizontal tube furnace play in activated carbon production? Master High-Precision Activation

- Why is atmosphere control critical for lignin carbonization? Expert Tips for High-Temperature Tube Furnace Success