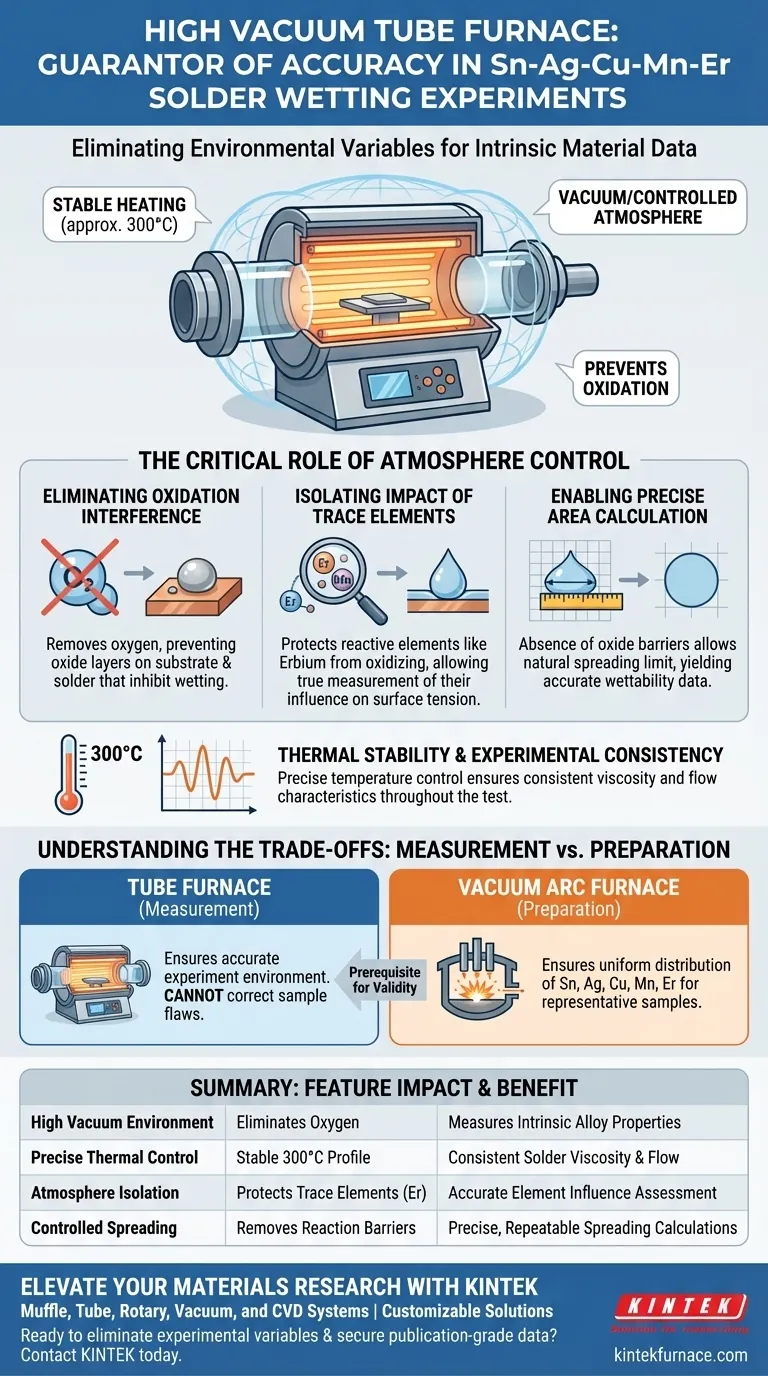

A high vacuum tube furnace acts as the guarantor of experimental validity by eliminating environmental variables that distort wetting data. Specifically, it provides a stable heating environment (typically around 300°C) while maintaining a vacuum or controlled atmosphere to prevent the oxidation of both the Sn-Ag-Cu-Mn-Er solder and the copper substrate. This isolation ensures that observed spreading areas are purely a result of the alloy's physical properties, rather than surface contamination or oxide layer interference.

Core Takeaway: The accuracy of wetting experiments relies entirely on measuring the intrinsic interactions between the solder and the substrate. A high vacuum tube furnace secures this by preventing oxidation, ensuring that data points regarding surface tension and capillary action reflect the true influence of alloying elements like Erbium.

The Critical Role of Atmosphere Control

Eliminating Oxidation Interference

The primary threat to accuracy in wetting experiments is oxygen.

When exposed to heat, both the copper substrate and the solder alloy are prone to rapid oxidation.

A high vacuum tube furnace removes this variable, ensuring the solder spreads over a pristine metal surface rather than an oxide layer, which would drastically inhibit wetting.

Isolating the Impact of Trace Elements

In complex alloys like Sn-Ag-Cu-Mn-Er, trace elements are added to modify performance.

Specifically, researchers need to measure how elements like Erbium (Er) influence surface tension and capillary action.

Without a vacuum environment, these reactive elements could oxidize before affecting the wetting process, leading to false conclusions about their efficacy.

Enabling Precise Area Calculation

The spreading area is the key metric for determining wettability.

Because the vacuum environment prevents the formation of reaction barriers (oxides), the solder can spread to its natural limit.

This allows for the precise calculation of the spreading area, providing data that is a true representation of the material's capability.

Thermal Stability and Experimental Consistency

Controlled Heating Profiles

Accuracy requires more than just a clean atmosphere; it requires precise temperature control.

The tube furnace maintains a stable temperature, such as the 300°C required for these specific solder experiments.

This stability ensures that the viscosity and flow characteristics of the solder are consistent throughout the test duration.

Understanding the Trade-offs

The limit of the Tube Furnace

While the high vacuum tube furnace ensures the accuracy of the experiment, it cannot correct flaws in the sample.

The furnace can only measure the properties of the alloy placed inside it; it does not homogenize the material.

Dependency on Prior Preparation

For the data to be valid, the alloy itself must be uniform before it enters the tube furnace.

This requires the use of a vacuum arc furnace during the melting and preparation stage.

The arc furnace ensures the uniform distribution of Tin (Sn), Silver (Ag), Copper (Cu), Manganese (Mn), and Erbium (Er) so that the sample tested in the tube furnace is representative of the bulk material.

Making the Right Choice for Your Goal

To ensure your research yields publication-grade data, you must align your equipment with your specific experimental phase.

- If your primary focus is experimental measurement: Prioritize the high vacuum tube furnace to control atmosphere and temperature, ensuring that oxidation does not skew your wetting and spreading area calculations.

- If your primary focus is alloy synthesis: Focus on the vacuum arc furnace to ensure the homogeneous distribution of trace elements like Erbium and Manganese before testing begins.

Accuracy in wetting experiments is not just about the measurement tool; it is about preserving the chemical integrity of the materials during the thermal process.

Summary Table:

| Feature | Impact on Wetting Experiments | Benefit to Data Accuracy |

|---|---|---|

| High Vacuum Environment | Eliminates oxygen and prevents surface oxidation | Measures intrinsic physical properties of the alloy |

| Precise Thermal Control | Maintains stable 300°C heating profiles | Ensures consistent solder viscosity and flow behavior |

| Atmosphere Isolation | Protects reactive trace elements like Erbium (Er) | Accurate assessment of alloying element influence |

| Controlled Spreading | Removes oxide-based reaction barriers | Provides precise, repeatable spreading area calculations |

Elevate Your Materials Research with KINTEK

Precision in wetting and spreading experiments demands absolute environmental control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory requirements.

Whether you are synthesizing complex Sn-Ag-Cu-Mn-Er alloys or measuring critical surface tension data, our high-temperature furnaces provide the thermal stability and vacuum integrity your research deserves.

Ready to eliminate experimental variables and secure publication-grade data?

Contact KINTEK today to discuss your custom furnace needs

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the applications of fluidized bed vertical tube furnaces? Achieve Uniform Heating for Powdered Materials

- What role does a vacuum tube furnace play as a reactor during the coal gasification reaction stage?

- What is the role of a vacuum tube furnace during the final thermal treatment stage of Fe3O4@CSAC catalysts?

- How do resistance heating tube furnaces generate heat? Master Precise Temperature Control

- Why is a high-precision programmable tube furnace required for N-doped TiO2@C composites? Expert Thermal Solutions

- What specific process conditions does a laboratory tube furnace provide? Optimize Biomass Carbonization Success

- Why is it necessary to precisely control the oxygen flow rate in a tube furnace? Optimize Li-Deficient Composites

- How does a horizontal dual-zone tube furnace facilitate WSe2 CVT growth? Precision Thermal Gradient Control