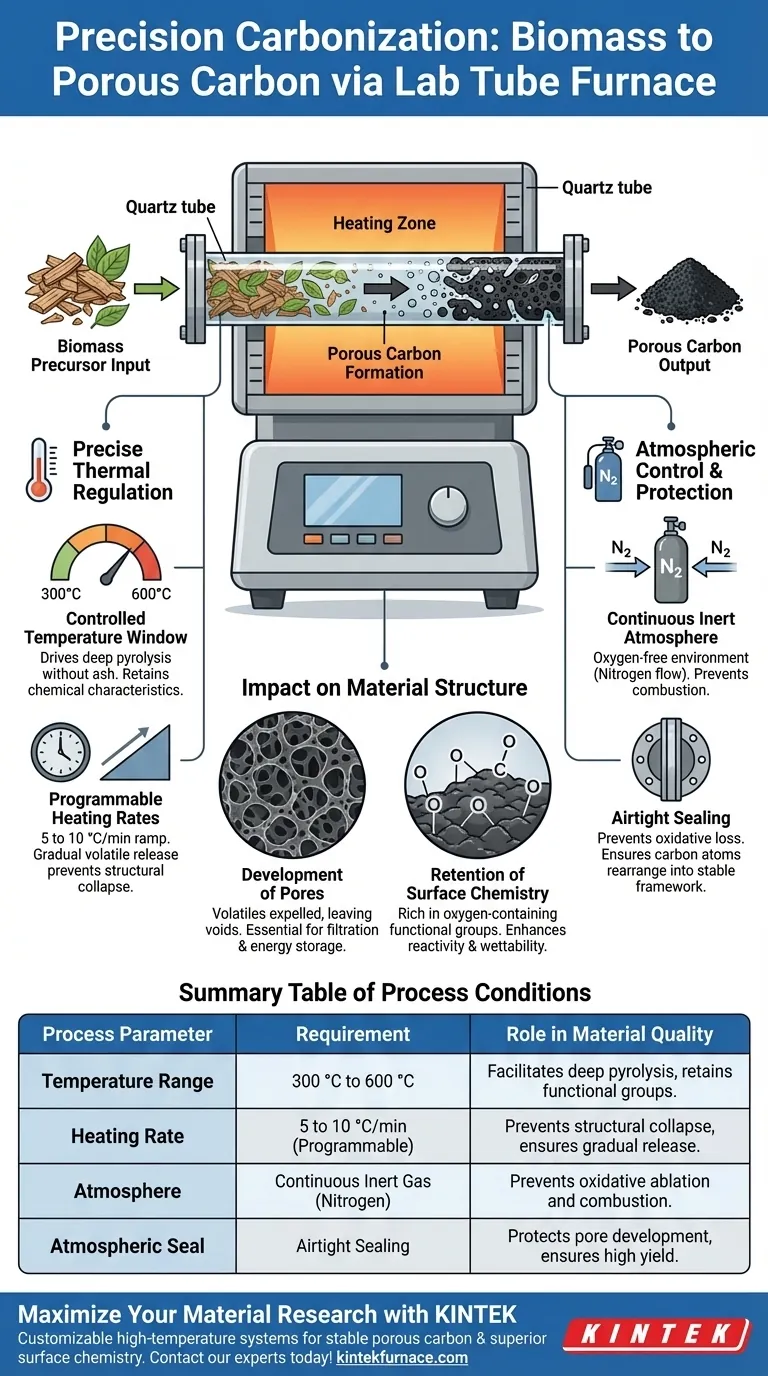

A laboratory tube furnace provides a strictly controlled thermal and atmospheric environment essential for converting biomass precursors into high-quality porous carbon. Specifically, it maintains a precise temperature range typically between 300 °C and 600 °C with a programmed heating rate of 5 to 10 °C/min, while ensuring a continuous nitrogen atmosphere to prevent material combustion.

By combining airtight sealing with programmable thermal regulation, the tube furnace facilitates deep carbonization without oxidation. This specific environment is critical for developing a stable porous carbon structure while preserving essential oxygen-containing functional groups.

Precise Thermal Regulation for Pyrolysis

To transform biological matter into porous carbon, the equipment must facilitate deep pyrolysis—the thermal decomposition of organic material—without burning it to ash.

Controlled Temperature Window

The tube furnace operates within a specific thermal window, typically 300 °C to 600 °C for this application. This range is sufficient to drive off volatile components and induce carbonization but is often low enough to retain specific chemical characteristics of the precursor.

Programmable Heating Rates

A critical feature is the ability to ramp temperature strictly at 5 to 10 °C/min. This slow, steady increase ensures that volatile gases are released gradually. A controlled release prevents structural collapse or cracking, ensuring the final carbon skeleton remains intact and porous.

Atmospheric Control and Protection

The physical design of a tube furnace is centered around its ability to isolate the sample from the ambient environment.

Continuous Inert Atmosphere

The furnace is designed to operate under a flow of inert gas, most commonly nitrogen. This creates an oxygen-free environment within the tube.

Preventing Oxidative Loss

If biomass is heated to 600 °C in the presence of air, it simply burns away. The tube furnace’s airtight design prevents this oxidative ablation. Instead of combusting, the biomass undergoes carbonization, where the carbon atoms rearrange into a stable framework.

Impact on Material Structure

The specific process conditions provided by the furnace directly dictate the quality of the final carbon material.

Development of Pores

As the temperature rises and volatiles are expelled under the nitrogen shield, a network of voids is left behind. This process converts the dense biomass into a material with developed pores, which is essential for applications like filtration or energy storage.

Retention of Surface Chemistry

Because the temperature is carefully capped (e.g., up to 600 °C) and oxidation is prevented, the resulting biochar is not just pure carbon. It remains rich in oxygen-containing functional groups, which can enhance the material's reactivity and wettability.

Understanding the Trade-offs

While the tube furnace is ideal for high-precision carbonization, there are operational constraints to consider.

Volume Limitations

Tube furnaces generally have a small "hot zone" where the temperature is perfectly uniform. This limits the quantity of biomass that can be carbonized in a single batch compared to industrial kilns.

Sensitivity to Seal Integrity

The quality of the carbon depends entirely on the exclusion of oxygen. Any failure in the airtight seals or the nitrogen flow system will result in the partial combustion of the sample, ruining the pore structure and yield.

Making the Right Choice for Your Goal

When configuring a tube furnace for biomass carbonization, your specific objectives should dictate your process parameters.

- If your primary focus is Surface Chemistry: Stick to the lower end of the temperature range (300 °C – 500 °C) to maximize the retention of oxygen-containing functional groups on the carbon surface.

- If your primary focus is Structural Stability: Prioritize a slower heating rate (5 °C/min) to ensure volatiles exit the material gently, preserving the delicate porous framework.

Ultimately, the laboratory tube furnace serves as a precision tool that strictly governs the boundary between thermal decomposition and combustion to yield functionalized porous carbon.

Summary Table:

| Process Parameter | Requirement for Biomass Carbonization | Role in Material Quality |

|---|---|---|

| Temperature Range | 300 °C to 600 °C | Facilitates deep pyrolysis while retaining functional groups |

| Heating Rate | 5 to 10 °C/min (Programmable) | Prevents structural collapse; ensures gradual volatile release |

| Atmosphere | Continuous Inert Gas (Nitrogen) | Prevents oxidative ablation and sample combustion |

| Atmospheric Seal | Airtight Sealing | Protects pore development and ensures high yield |

Maximize Your Material Research with KINTEK

Ready to achieve precision in biomass carbonization? Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding lab environments. Our high-temperature furnaces are fully customizable to meet your unique research needs, ensuring stable porous carbon structures and superior surface chemistry every time.

Take the next step in material excellence—contact our experts today to find the perfect furnace for your laboratory!

Visual Guide

References

- Xing Wang, Long Zhang. Ultrahigh and kinetic-favorable adsorption for recycling urea using corncob-derived porous biochar. DOI: 10.1038/s41598-024-58538-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for long-term heat treatment of FeTeSe crystals? Achieve High Crystallinity & Uniformity

- What is the function of vacuum-sealed tubes and controlled heating? Master Ruthenium Precursor Embedding

- How is a tube furnace designed to operate at 1200°C? Precision Engineering for Extreme Heat

- Why is a high-temperature tube furnace required for LK-99 sintering? Achieve Precise Superconductor Phase Transformation

- What is the role of a vacuum tube furnace during the final thermal treatment stage of Fe3O4@CSAC catalysts?

- What are the advantages of multi-zone tube furnaces? Achieve Superior Thermal Control for Advanced Materials Processing

- What critical environmental conditions does a tube furnace provide for volcanic rock thermal cycling? Expert Guide

- How does the working temperature range affect the choice of a vertical tube furnace? Optimize Your Lab's Performance and Budget