In short, fluidized bed vertical tube furnaces are used in any application where highly uniform and efficient heating of powdered or granular materials is essential. They are staples in advanced materials science, chemical processing, and energy production, handling processes from creating new alloys and catalysts to incinerating waste and generating power.

The core value of this technology lies in its unique method of heat transfer. By suspending solid particles in an upward-flowing hot gas, the furnace creates a "fluidized bed" that behaves like a boiling liquid, ensuring every particle is heated uniformly and rapidly. This overcomes the limitations of conventional furnaces where heat struggles to penetrate a static pile of material.

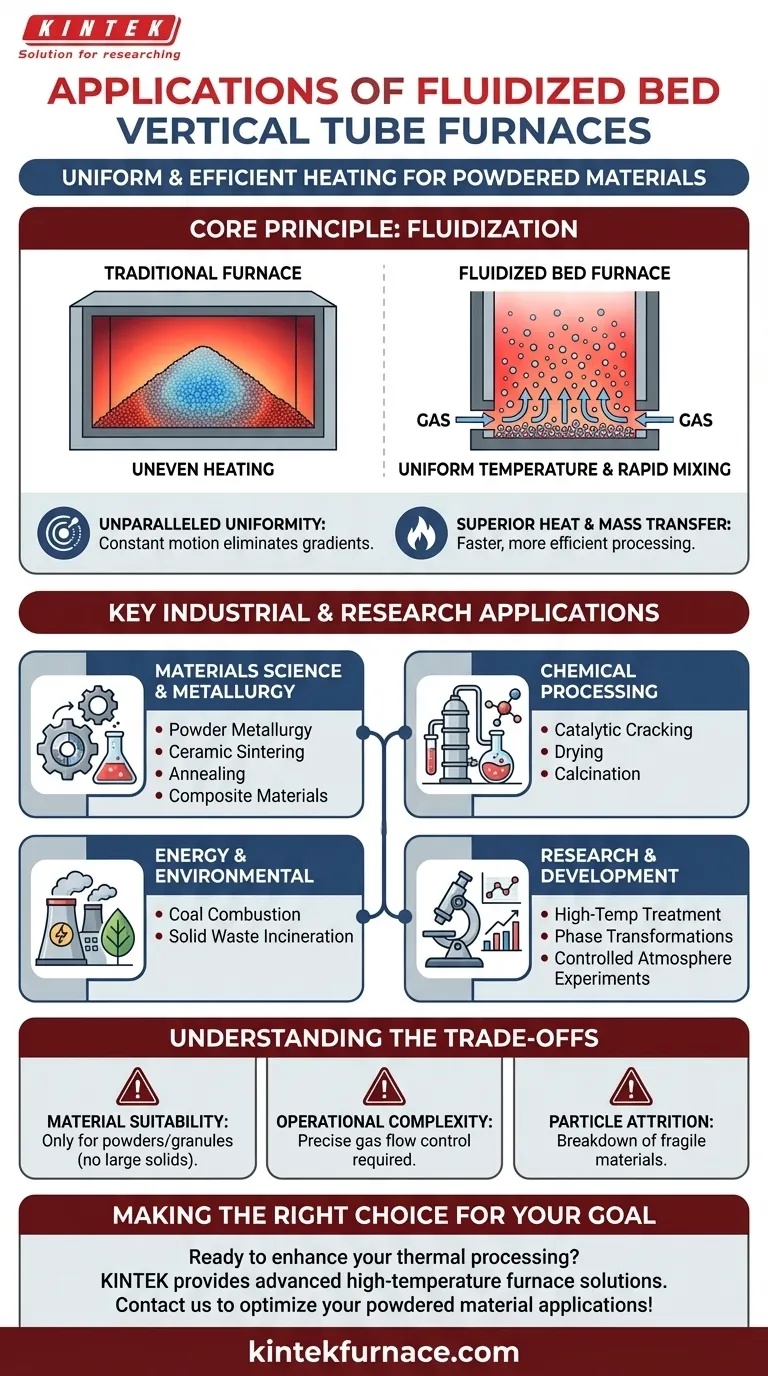

The Core Principle: Why a "Fluidized Bed"?

The "fluidized bed" is the key differentiator. Understanding this mechanism reveals why these furnaces are chosen for specific, demanding tasks.

What is Fluidization?

Fluidization is the process of making a bed of solid particles (like sand or a chemical powder) behave like a fluid. This is achieved by passing a gas upward through the particles at a high enough velocity to suspend them, causing them to churn and mix vigorously.

Imagine blowing air through the bottom of a container of sand. At a certain flow rate, the sand will begin to bubble and flow like water. This is a fluidized bed.

The Benefit: Unparalleled Temperature Uniformity

In a traditional furnace, a pile of powder heats unevenly—the outside gets hot while the core remains cool. In a fluidized bed, the constant, rapid mixing eliminates temperature gradients entirely.

Every single particle is surrounded by the heating gas and is in constant motion, ensuring the entire sample reaches and maintains a precise, uniform temperature.

The Advantage: Superior Heat & Mass Transfer

This constant motion and the immense surface area of the suspended particles lead to extremely high rates of heat transfer. Processes that would take hours in a conventional furnace can be completed much more quickly and efficiently.

This same principle also applies to mass transfer, making these furnaces ideal for chemical reactions where a gas must react with the surface of a solid particle.

Key Industrial & Research Applications

The unique properties of fluidization make these furnaces indispensable across several high-tech fields.

In Materials Science and Metallurgy

These furnaces are crucial for processing powdered metals and ceramics. The precise temperature control prevents overheating and ensures consistent material properties.

Key processes include powder metallurgy, ceramic sintering, annealing of metal powders, and creating advanced composite materials.

In Chemical Processing

The chemical industry relies on fluidized beds for reactions involving solid catalysts or reagents. The excellent mixing and heat transfer maximize reaction rates and product yield.

Common applications are catalytic cracking in petroleum refining, drying of granular raw materials, and calcination (high-temperature decomposition) of minerals.

In Energy and Environmental Management

The furnace's high combustion efficiency and ability to handle various fuel types make it valuable for energy and waste treatment.

It is used for clean and efficient coal combustion in power plants and for the incineration of solid waste, where the uniform high temperature ensures complete destruction of harmful materials.

In the Laboratory for Research & Development

In a research setting, these furnaces are used to develop and test new materials or simulate large-scale industrial processes.

Researchers use them for high-temperature heat treatment (like quenching), studying phase transformations, and conducting experiments under controlled atmospheres (e.g., in inert argon or reactive hydrogen).

Understanding the Trade-offs

While powerful, these furnaces are not a universal solution. Their specialized nature comes with specific limitations.

Material Suitability

The most significant constraint is that these furnaces only work with powders or small granules that can be fluidized. They are unsuitable for heating large, solid objects or bulk materials.

Operational Complexity

Achieving and maintaining a stable fluidized bed requires precise control over gas flow rates. Incorrect flow can lead to poor fluidization (channeling) or blowing the material out of the furnace (elutriation).

Particle Attrition

The constant, energetic collisions between particles can cause them to break down or wear away over time. This "attrition" can be a concern when working with fragile or expensive materials.

Making the Right Choice for Your Goal

Selecting the correct thermal processing tool depends entirely on your material and your objective.

- If your primary focus is process efficiency and uniformity for powders: This furnace is the superior choice for its rapid heat transfer and elimination of hot spots.

- If your primary focus is research and new material synthesis: Its precise control over temperature and atmosphere makes it an invaluable laboratory tool for repeatable experiments.

- If you are working with large, solid, or non-granular samples: A conventional muffle furnace or standard tube furnace would be a more practical and appropriate choice.

By understanding its core principle of fluidization, you can leverage this furnace's unique capabilities for highly controlled and efficient thermal processing.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Materials Science | Powder metallurgy, ceramic sintering, annealing, composite material creation |

| Chemical Processing | Catalytic cracking, drying, calcination of minerals |

| Energy & Environmental | Coal combustion, solid waste incineration |

| Research & Development | High-temperature heat treatment, phase transformation studies, controlled atmosphere experiments |

Ready to enhance your thermal processing with precision and efficiency? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our fluidized bed vertical tube furnaces can optimize your powdered material applications and drive innovation in your projects!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide